Light modulator

A dimming device and variable technology, applied in lighting devices, light sources, electric light sources, etc., can solve the problems of destroying electronic components or circuits, not getting a sense of snapping, and not being able to lengthen through holes, etc., to prevent temperature rise, The effect of ensuring the snap feeling and improving the static resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

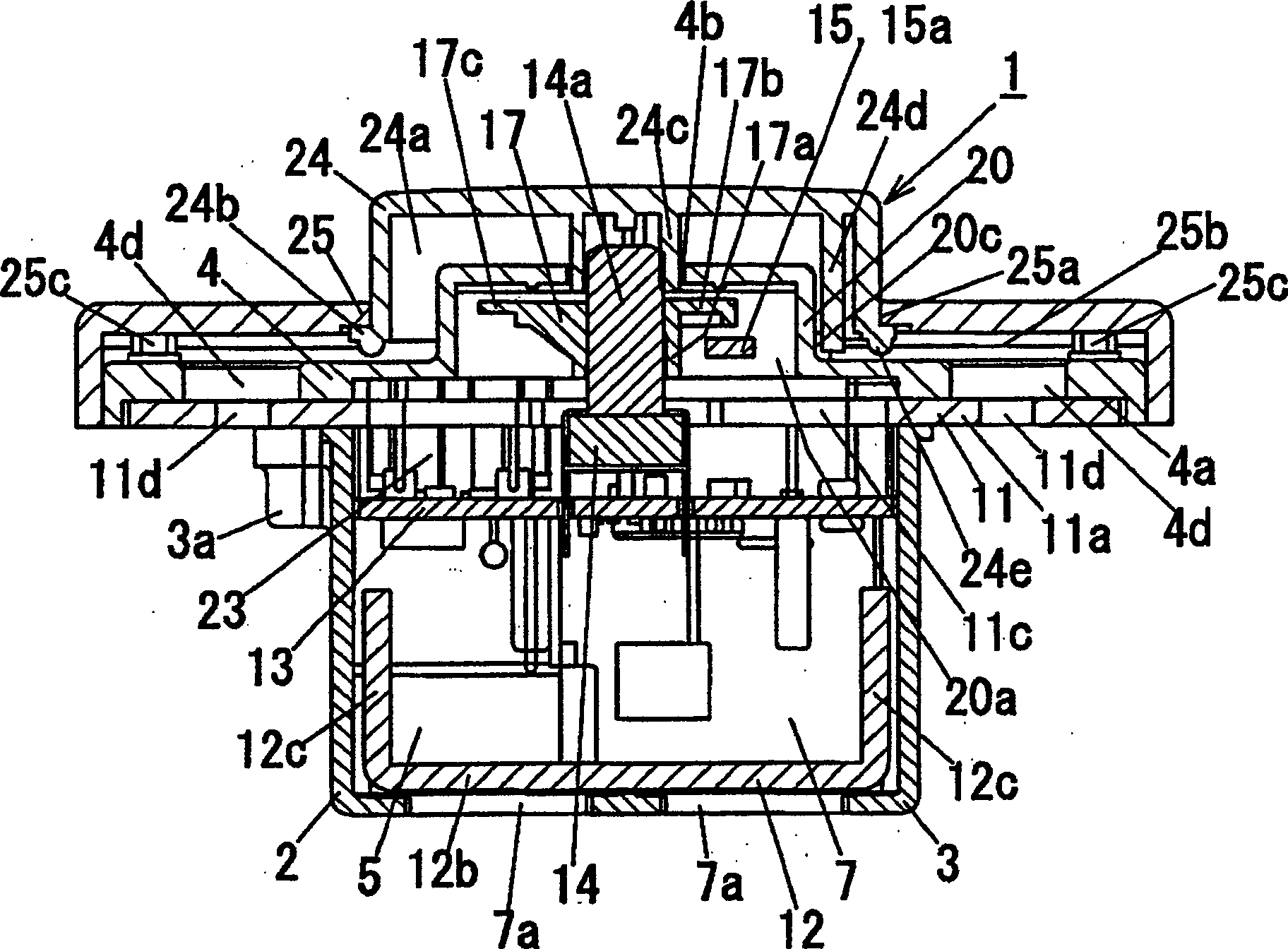

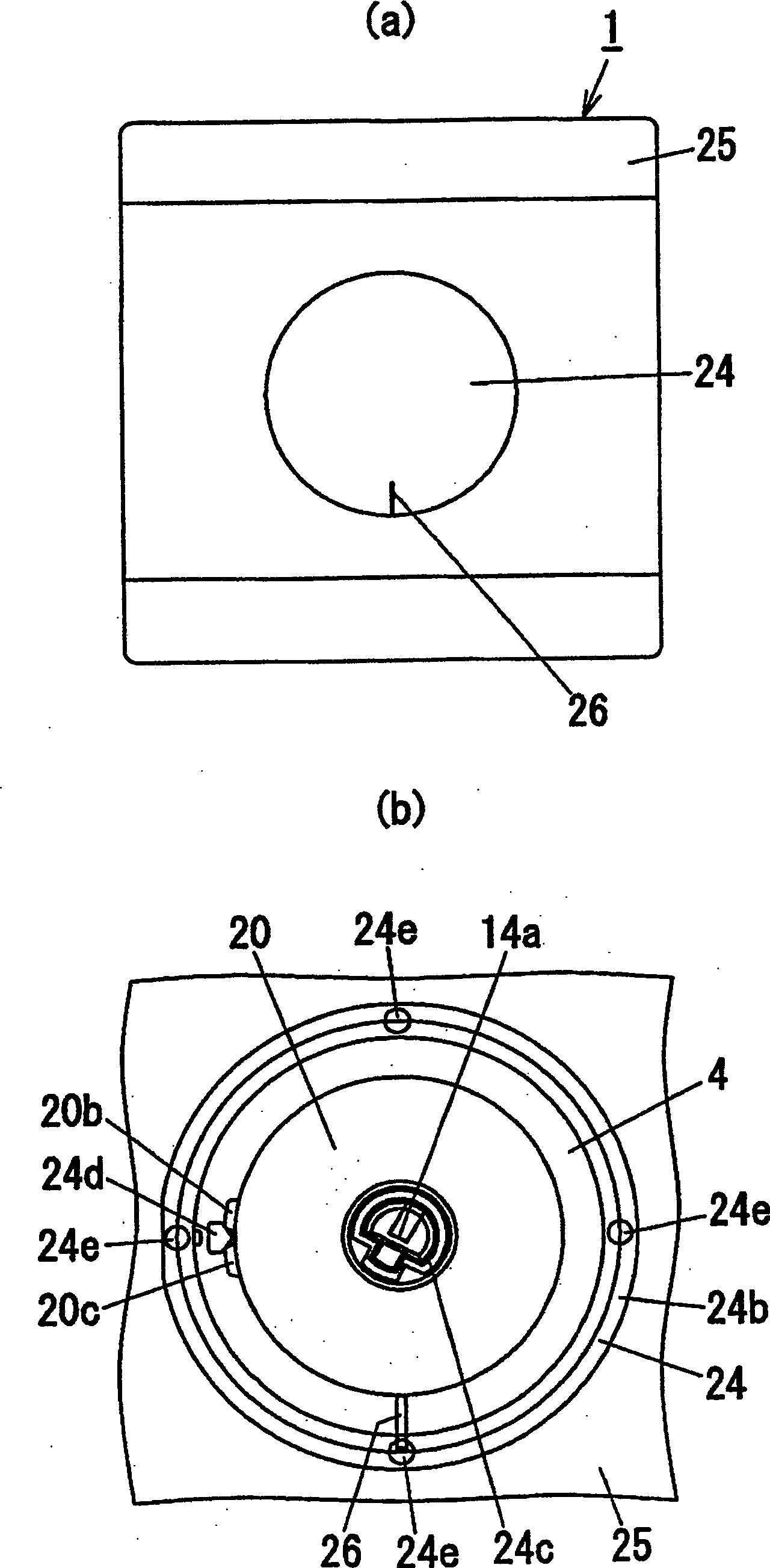

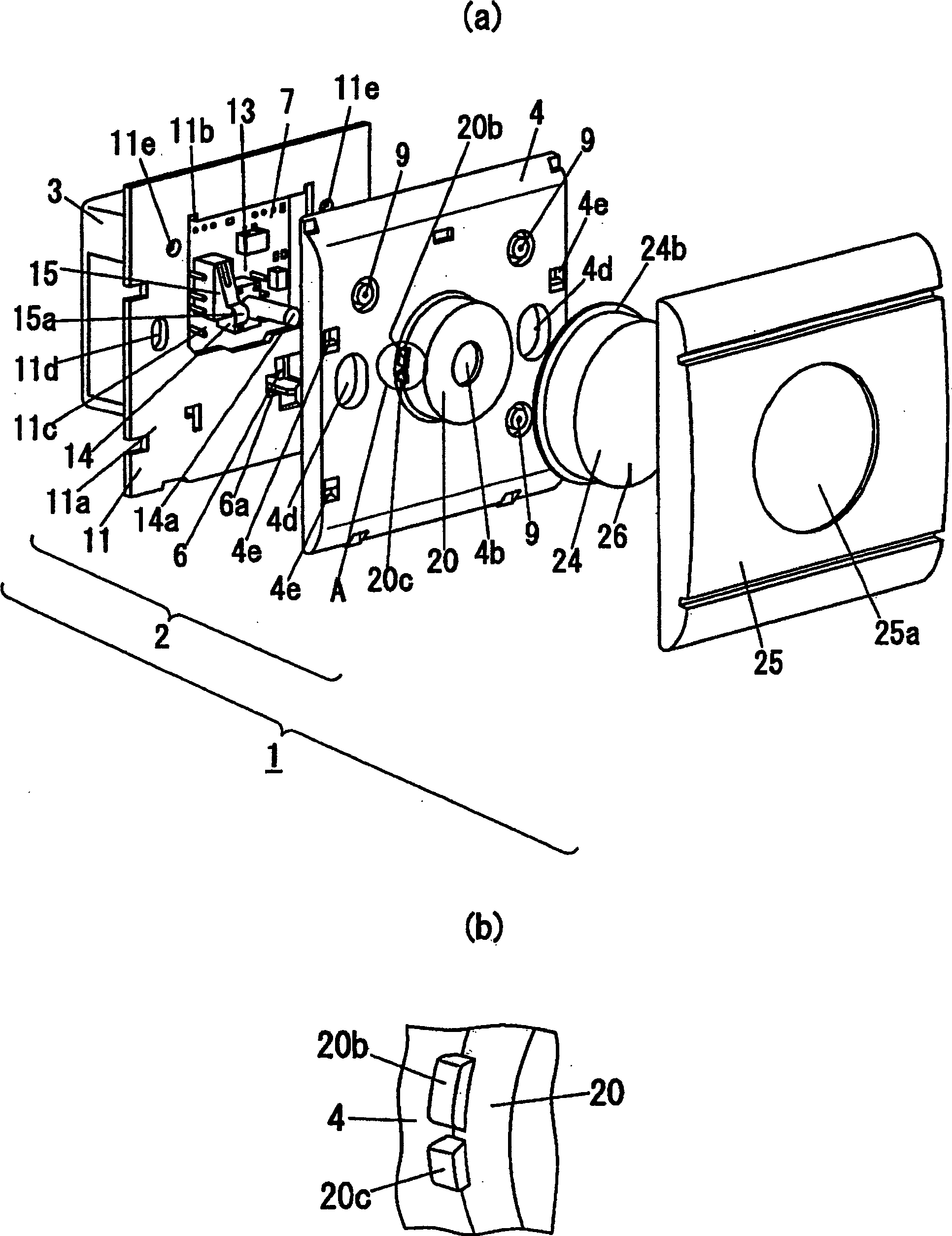

[0026] Below, refer to Figure 1 to Figure 5 The lighting device 1 of the present invention will be described. In addition, in figure 1 Among them, the front direction is the upper side of the dimming device 1, the left direction is the right side of the dimming device 1, the right direction is the left side of the dimming device 1, the upper direction is the surface side of the dimming device 1, and the lower direction is The back side of the dimming device 1 .

[0027] The dimming device 1 of the present invention, such as figure 1As shown, it has: a circuit board part 13, including a rotary rheostat 14 for dimming control setting with a rotating operation shaft 14a, and a switch between an external power supply (not shown) and a lighting load (not shown). The switch 15 for conducting electricity between them; the body 2 has a through hole 4b that rotatably penetrates the inner peripheral surface of the operation shaft 14a close to the operation shaft 14a, and protrudes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com