Method for representing high-phosphorus iron ore dynamic reaction stage

A high-phosphorus iron ore, reaction stage technology, applied in furnaces, furnace types, fluidized bed furnaces, etc., can solve the problems of difficult to accurate and stable information, incomplete testing methods, surface and crystal defects, etc., to achieve high sensitivity, Reliable and practical judgment and characterization method, the effect of the method is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

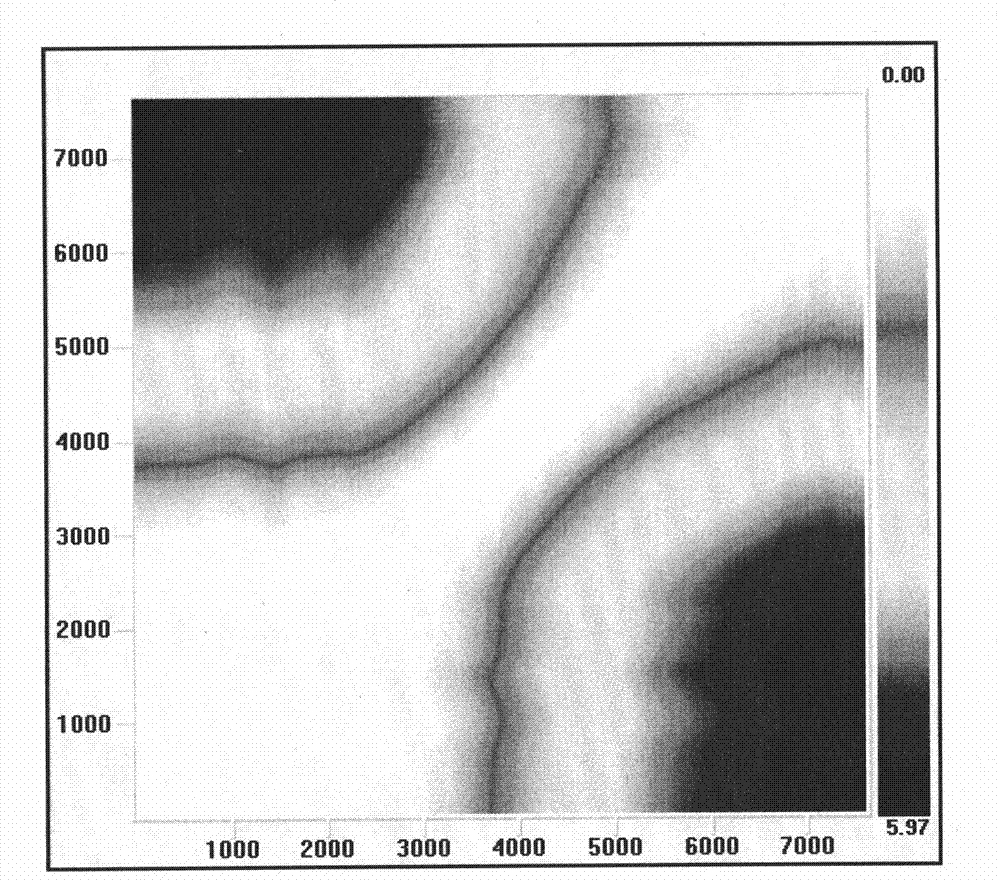

[0018] In the direct smelting reduction test of Huimin high phosphorus iron ore, the thermogravimetric experiment was used for analysis. The experimentally obtained differential thermal scanning calorimetry data is made into a dynamic map with VRA software (such as figure 1 ). It can be seen from the figure that [0, 3000] is the phase interface reaction stage, [3000, 5000] is the one-dimensional diffusion stage, and after 5000 points is the two-dimensional diffusion stage.

Embodiment 2

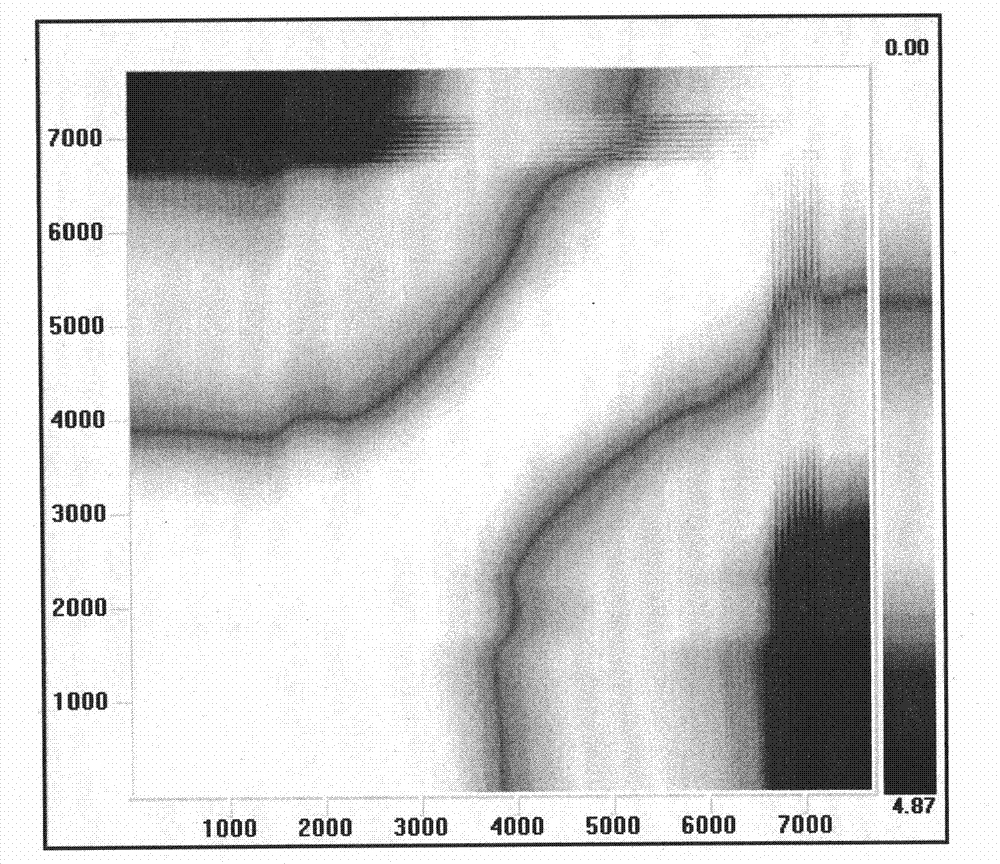

[0020] In the direct smelting reduction test of Luojing high-phosphorite iron ore, the thermogravimetric test was used for analysis. The experimentally obtained differential thermal scanning calorimetry data is made into a dynamic map with VRA software (such as figure 2 ). It can be seen from the figure that [0, 3200] is the phase interface reaction stage, [3200, 5500] is the one-dimensional diffusion stage, and after 5500 points is the two-dimensional diffusion stage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com