Light fitting

A technology of lamps and chambers, which is applied in the direction of damage prevention measures for lighting devices, lighting devices, cooling/heating devices for lighting devices, etc., and can solve problems such as light decay, affecting service life, affecting air circulation effects, and heat dissipation efficiency. Achieve the effects of avoiding light decay, prolonging service life, improving airflow and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

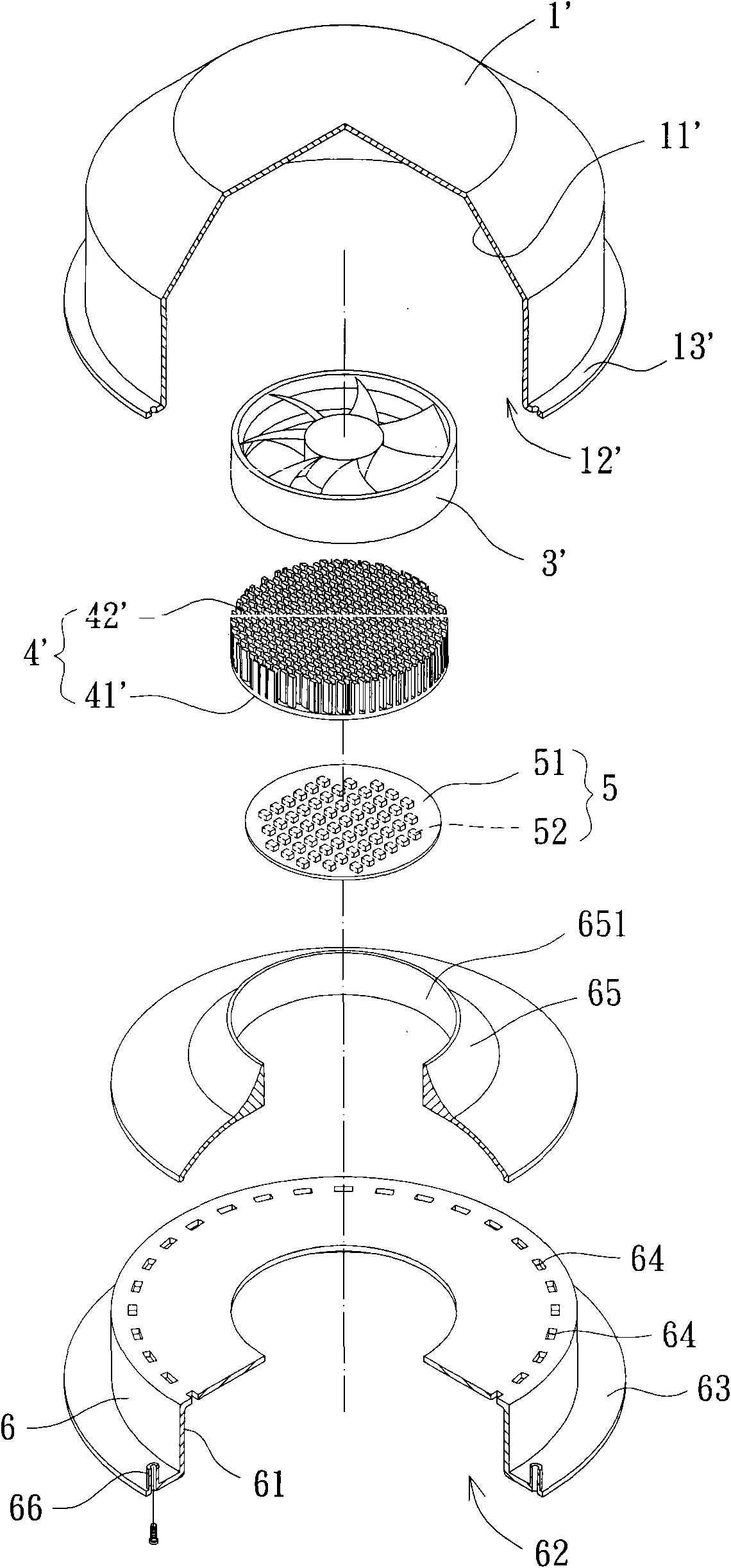

[0044] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

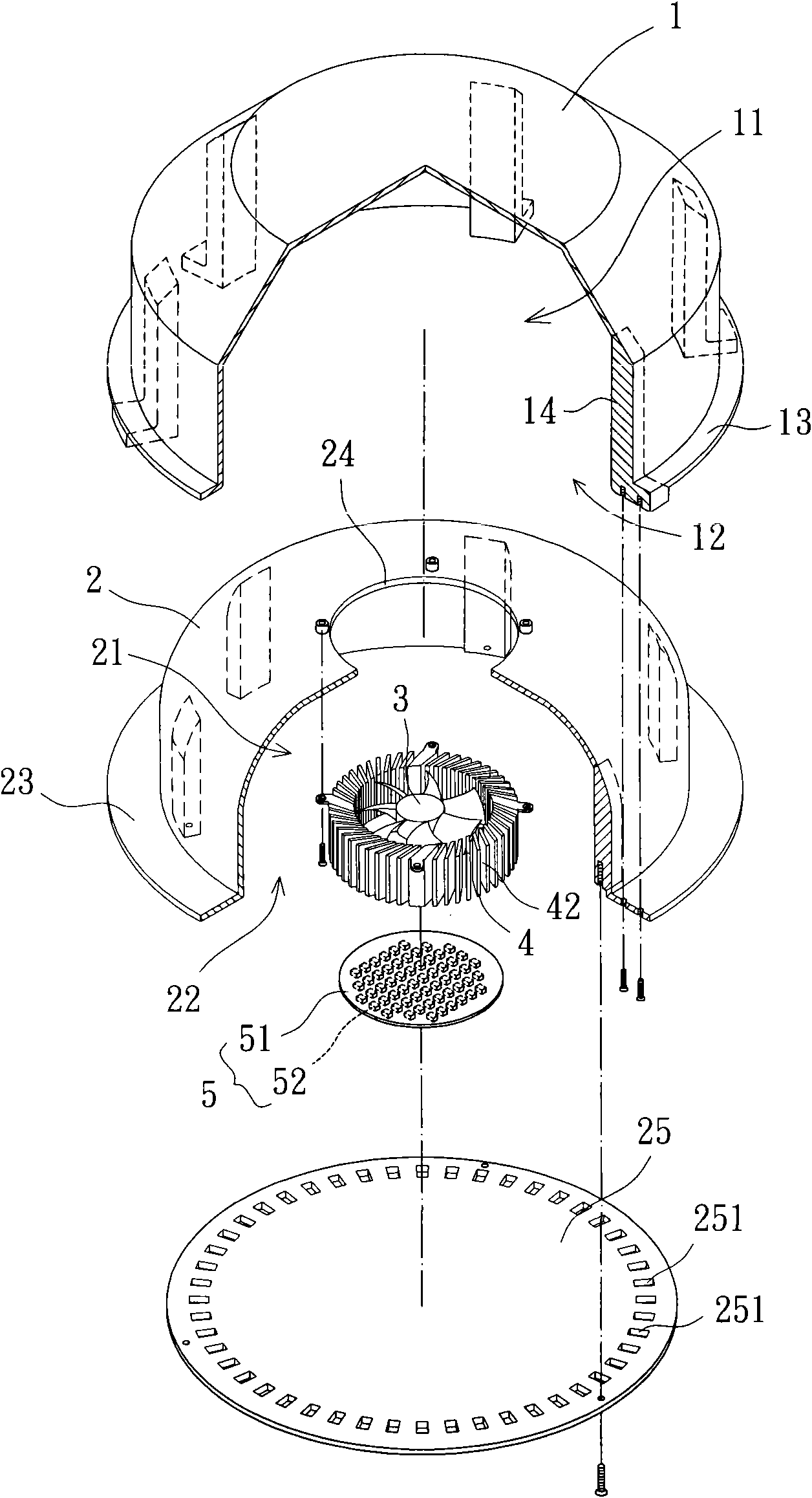

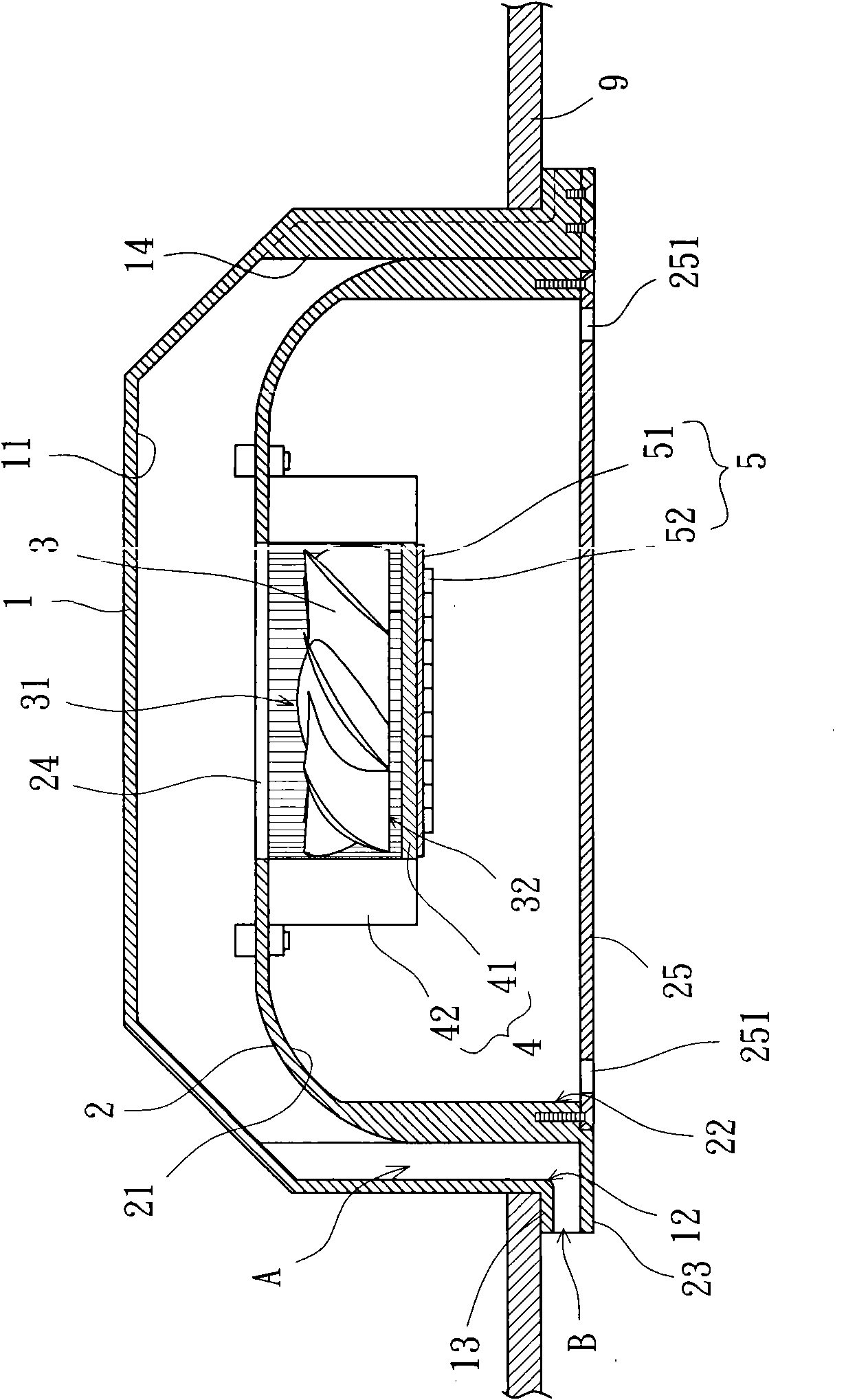

[0045] Please refer to figure 1 and 2 As shown, the lamp according to the first embodiment of the present invention includes an outer cover 1 , an inner shell seat 2 , a fan 3 , a heat sink 4 and a light emitting element 5 . Wherein, the inner shell base 2 is arranged in the outer cover 1, and an airflow channel A is formed between the outer cover 1 and the inner shell base 2, the fan 3 is arranged in a through hole 24 adjacent to the inner shell base 2, and the radiator 4 and the light-emitting element 5 are arranged in the inner shell seat 2, so that when the fan 3 is running, the airflow can be driven to circulate between the airflow passage A and the interior of the inner shell seat 2 through the through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com