Unmanned management method and system for test equipment

A technology of test equipment and management method, which is applied in the field of test equipment online monitoring system, can solve the problems of cumbersome wiring and limited number of network interfaces, and achieve the effects of avoiding accidents, ensuring the safety of life and property, and reducing accidents and economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

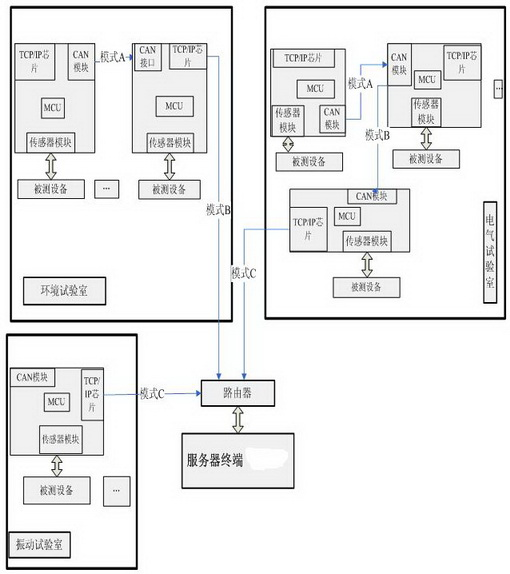

Embodiment 1

[0034] An information acquisition unit is installed on each test equipment in each laboratory, and each information acquisition unit has the same structure, mainly including sensors, microprocessor MCU, CAN module, and TCP / IP chip. The sensor in the information acquisition unit is used to collect the analog signal of the running test equipment. The microprocessor MCU obtains the analog signal collected by the sensor through the A / D interface, converts the analog signal into a digital signal, and amplifies the collected digital signal and data Processing and logical judgment whether there is a potential fault occurs, so as to give an alarm fault signal and make further analysis. The processed digital signal is converted into a differential signal through the CAN module and sent to the CAN interface, and then the differential signal is received and analyzed by the TCP / IP chip, and the differential signal is transmitted through the TCP / IP interface. The TCP / IP in each laboratory ...

Embodiment 2

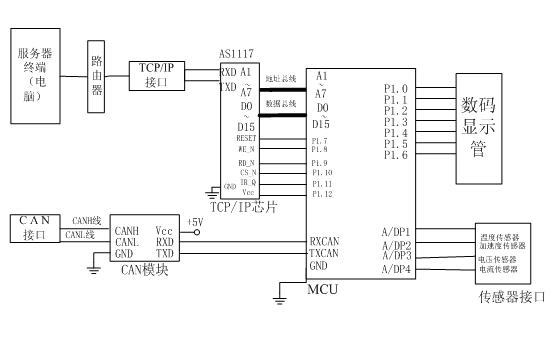

[0040] according to figure 2 As shown, the sensors include: a temperature sensor, an acceleration sensor, a voltage sensor, and a current sensor are respectively installed on the experimental equipment to obtain the digital signal of the experimental equipment, and transmit it to the A / DP1 to A / DP4 pins of the microprocessor MCU. The microprocessor MCU performs data processing and analysis, and then transmits it to the CAN module through the two lines RXCAN and TXCAN; the signal receiving pin RXD and signal sending pin TXD of the CAN module are respectively connected with the CAN signal receiving pin RXCAN and CAN signal of the MCU chip. The sending pin TXCAN is connected to complete the differential signal transmission of the CAN line, and collect the real-time status information of the running test equipment;

[0041] The CANH terminal and CANL terminal of the CAN module are respectively connected to the CANH line and the CANL line of the CAN interface to complete the diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com