Unmanned management method and system for test equipment

A test equipment, microprocessor technology, applied in the direction of instruments, comprehensive factory control, electrical program control, etc., can solve the problems of limited number of network interfaces, cumbersome wiring, etc., to ensure the safety of life and property, avoid accidents, and improve the economy. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

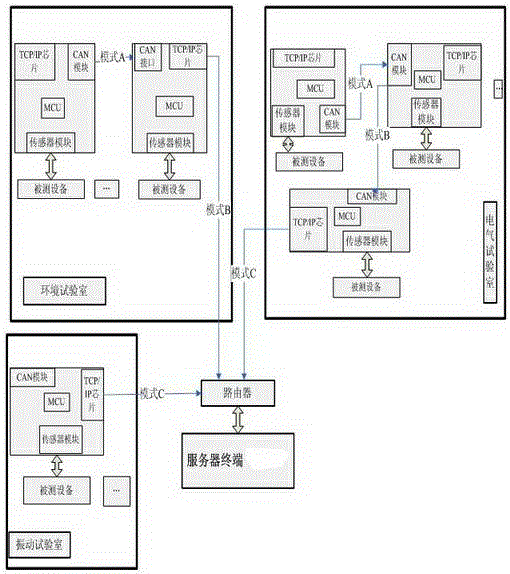

[0034] There are three main modes for differential signal transmission to the server terminal (computer) display (mode A or mode B or mode C):

[0035] Mode A, the CAN module in the information acquisition unit directly uploads the differential signal of the running test equipment to the CAN interface;

[0036] Mode B. The CAN interface in the information collection unit obtains the differential signal on the CAN interface of other information collection units in the CAN network, and at the same time uploads the differential signal on its own test equipment to the CAN network, and the microprocessor MCU obtains the differential signal. Through TCP / IP interface uploads the signal to the server terminal (computer);

[0037] Mode C. The information collection unit uploads the differential signal of the running test equipment to the server terminal (computer) through the TCP / IP interface. (see figure 1 )

[0038] Example 2

Embodiment 2

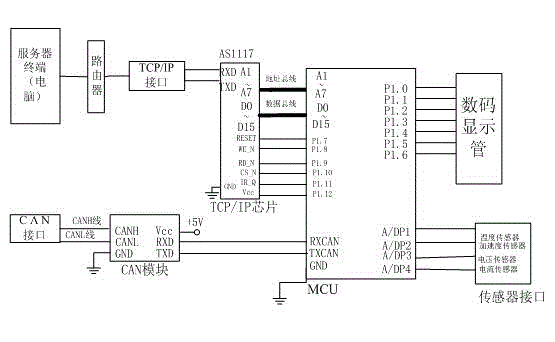

[0040] The CANH terminal and CANL terminal of the CAN module are respectively connected to the CANH line and the CANL line of the CAN interface to complete the differential signal transmission of the CAN line to the CAN interface, mainly through transmission mode A and mode B for differential signal transmission: mode A, information acquisition unit The CAN module of the CAN module directly uploads the differential signal of the running test equipment to the CAN interface; in mode B, the CAN interface in the information acquisition unit obtains the differential signal on the CAN interface of other information acquisition units in the CAN network, and at the same time uploads the differential signal on the own test equipment The differential signal is uploaded to the CAN network, the microprocessor MCU obtains the differential signal, and uploads the signal to the server terminal (computer) through the TCP / IP interface.

[0041] The TCP / IP chip (DM9000 model used in this example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com