750 kv lattice composite cross-arm insulator

An insulator and lattice-type technology, which is applied in the field of lattice-type composite cross-arm insulators, can solve problems such as the difficulty in meeting the mechanical strength requirements of 750kV transmission lines, large tower structure sizes, and large conductor loads, etc., to achieve easy self-cleaning, It is convenient to repair the tower and reduce the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

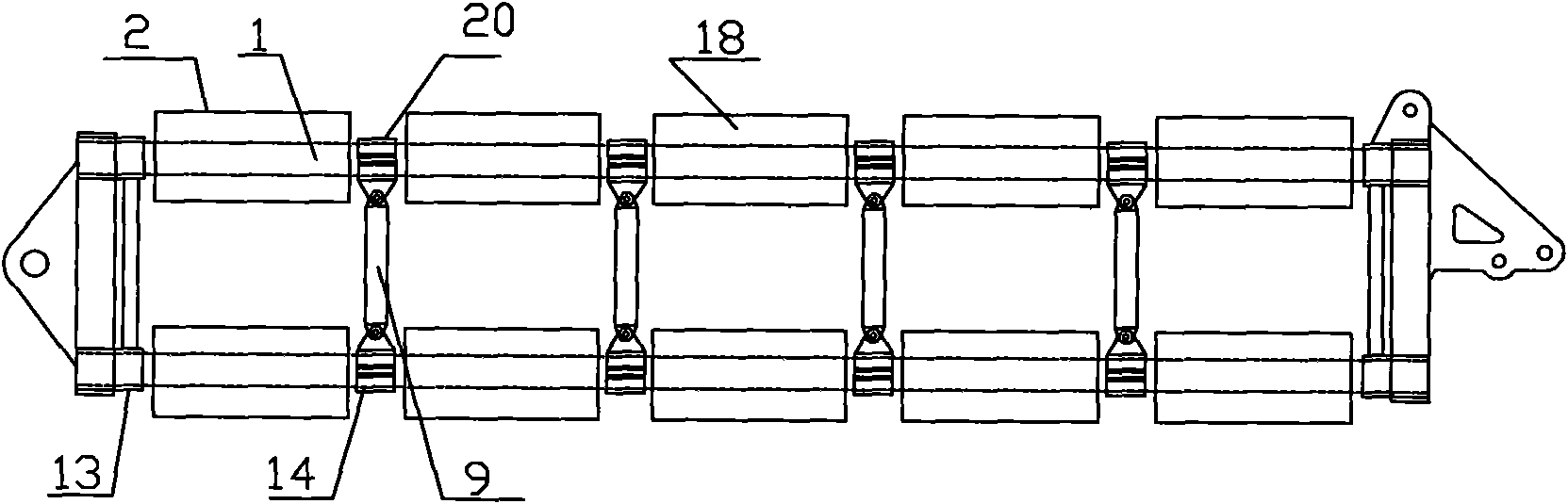

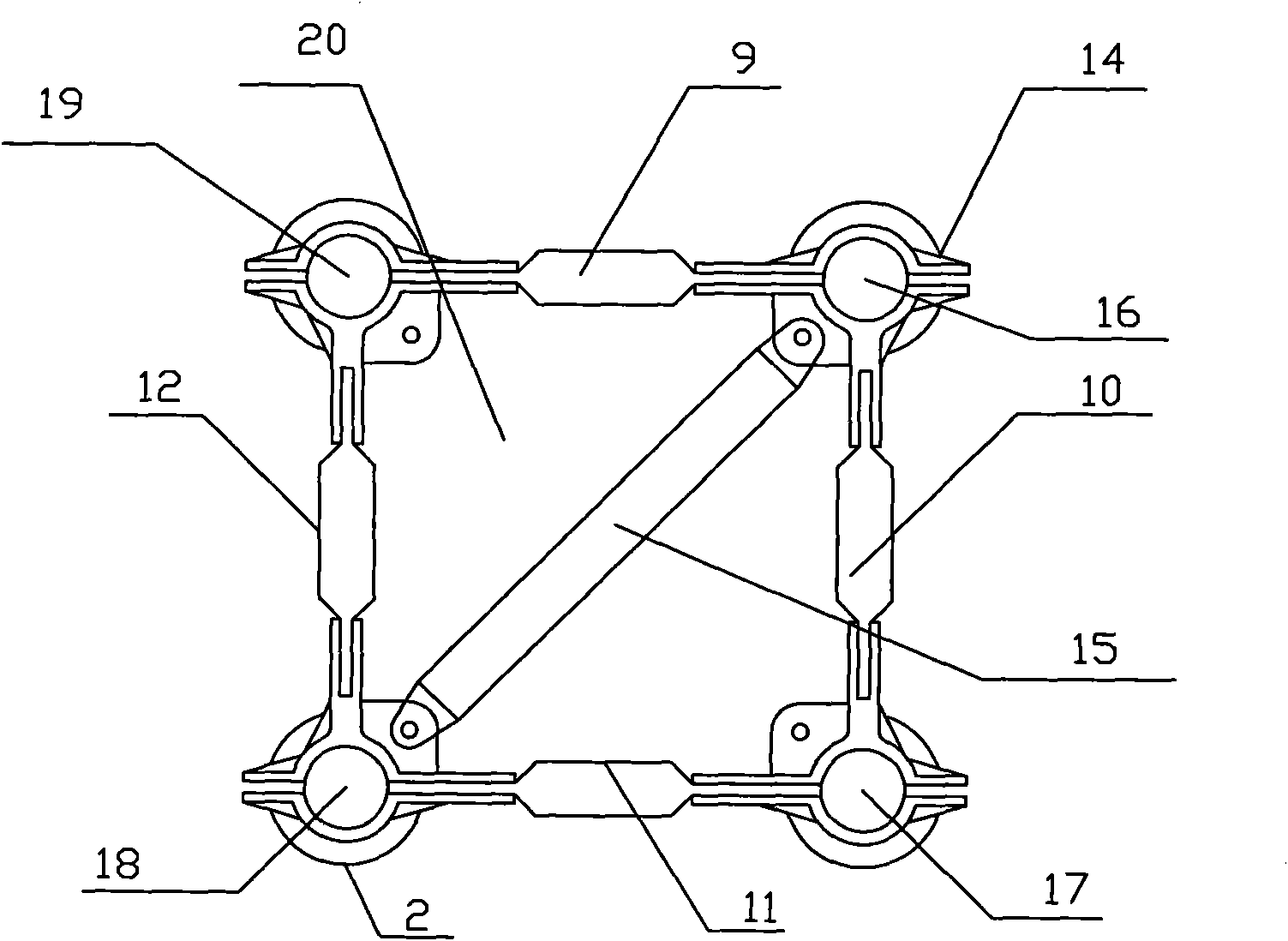

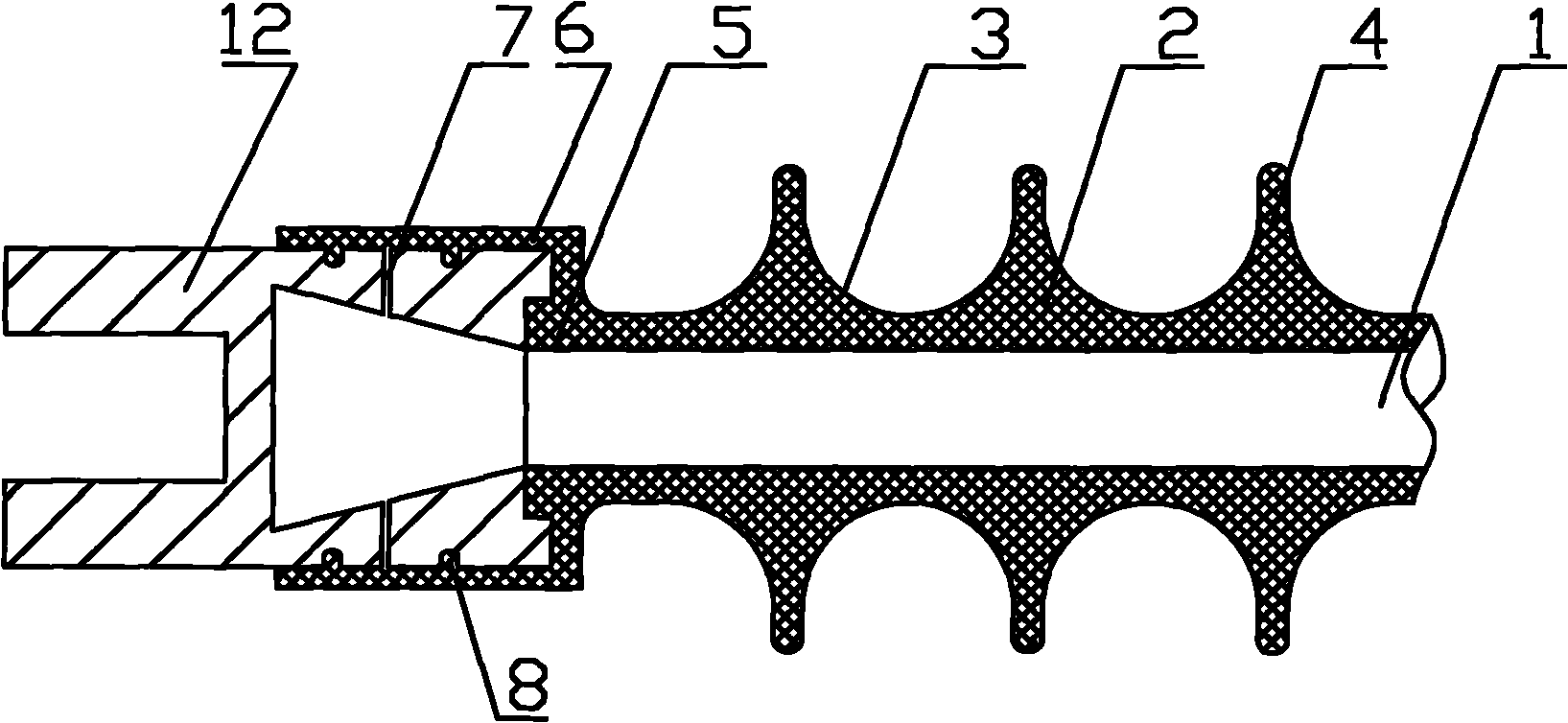

[0021] Such as figure 1 , 2 As shown, the 750kV composite cross-arm insulator in the preferred embodiment of the present invention includes four cross-arm insulators 16, 17, 18, and 19, and the cross-arm insulators 16, 17, 18, and 19 are connected by a connecting fastening device 19 , the connection and fastening device 19 includes four webs 9, 10, 11, 12; the webs 9, 10, 11, 12 are connected by hoops 14, and the cross-arm insulators 16, 17, 18, 19 Pass through the hoop 14 and fasten through the hoop 14, and the adjacent ends of the web bars 9, 10, 11, 12 are also fastened through the hoop 14; in order to play a reinforcing role, connect the fastening device 20 can also increase the oblique web bar 15, the ends of the web bar alternately, that is, the ends connected by 9,12 and the ends connected by 10,11 are bridged by the oblique web bar 15, and the connecting fastening device 20 is just formed by the web bar 9,10 , 11, 12 constitute a lattice structure mode, which greatly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com