Assembly for multiple connection in an electrical apparatus

A technology for electrical devices and components, which is applied to parts of connecting devices, conductive connections, electrical components, etc., can solve problems such as high voltage drop, affecting the modularity of electrical devices, and improper further engagement of screw heads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

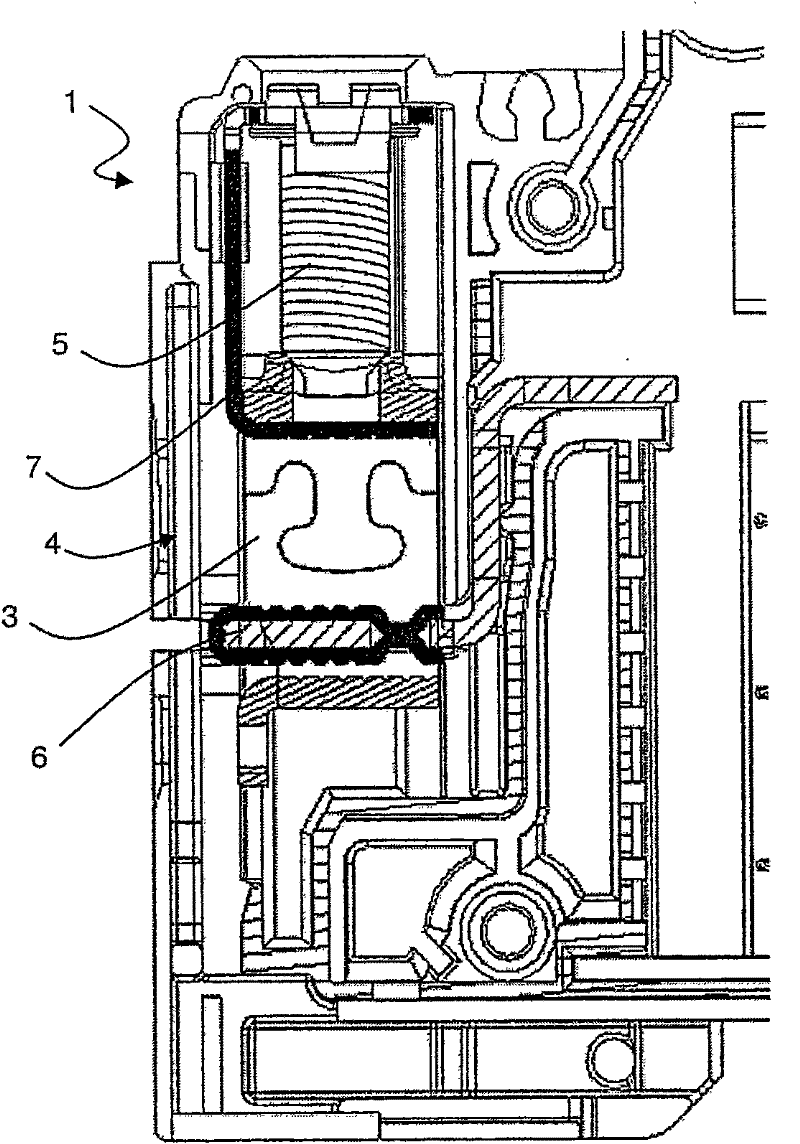

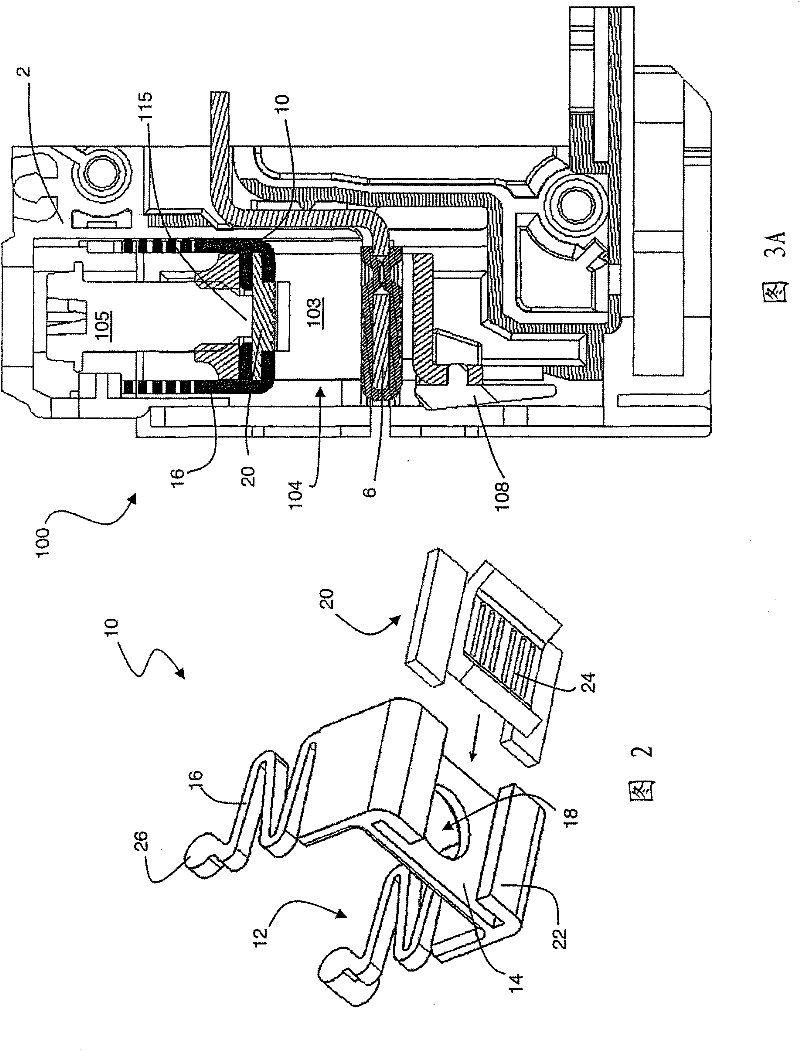

[0024] In order to simplify the description of the embodiments according to the present invention, the terminal assembly will be described corresponding to the insertion position shown in the drawings, wherein the channel for connecting the conductive member to the device is transverse for horizontal insertion, and the device Fastening of the internal electrical conductors is carried out by turning screws from the upper surface of the device. However, it should be understood that positional terms such as "horizontal", "top", "bottom" are in no way limiting to the object of the present invention. Also, geometric terms such as "orthogonal" and the like are to be understood in their mechanical sense, ie, with tolerances corresponding to strict mathematical definitions. Some expressions may be replaced by equivalent expressions, and shall be considered according to the functions they define in the technical features they represent.

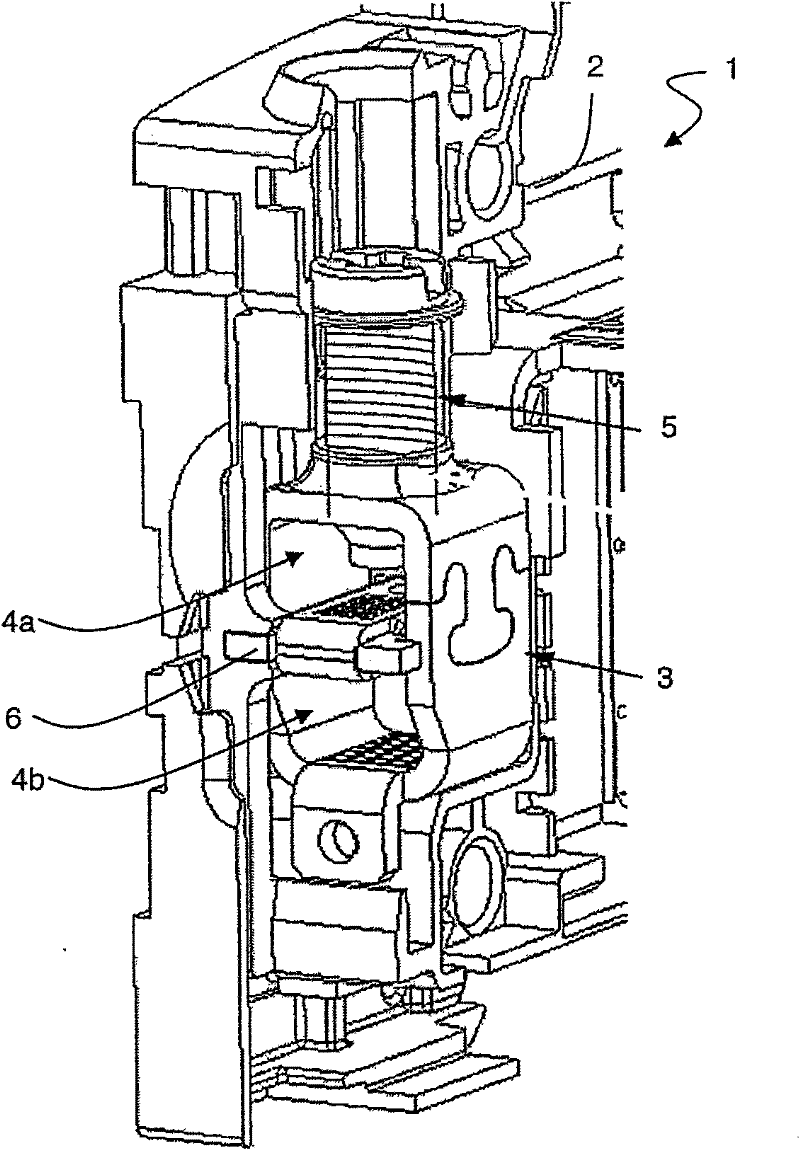

[0025] figure 2 An orthographic view of a fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com