Photovoltaic cell, and substrate for same

A technology for photovoltaic cells and substrates, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as difficult deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

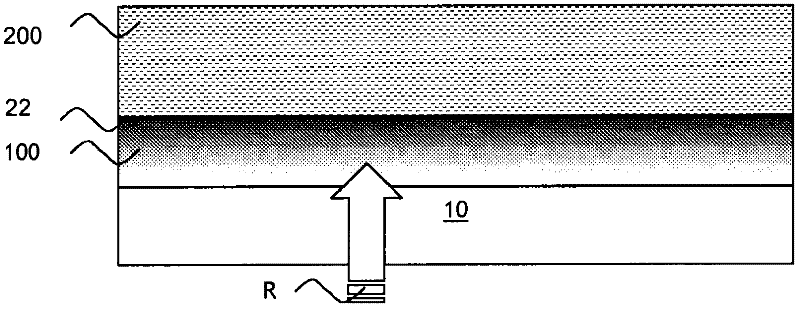

[0046] figure 1 Illustrated is a photovoltaic cell panel substrate 10 according to the invention having an absorbing photovoltaic material 200 with a transparent electrode coating 100 consisting of TCO on a major surface, said The transparent electrode coating 100 is also referred to as transparent conductive layer.

[0047] The panel substrate 10 is arranged in the photovoltaic cell in such a way that the panel substrate 10 is the first substrate through which incident radiation R passes before reaching the photovoltaic material 200 .

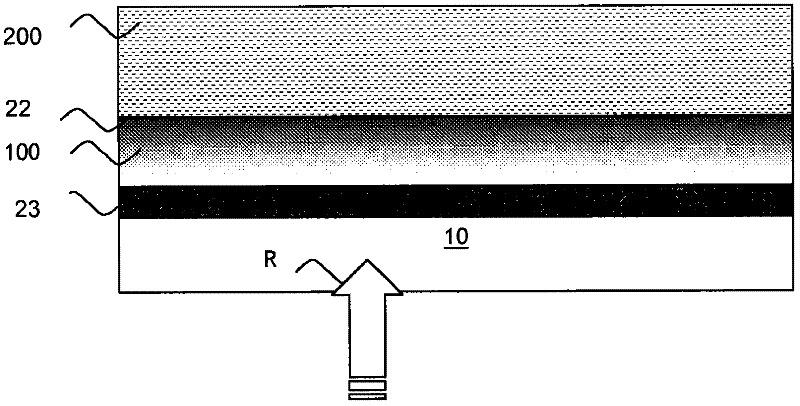

[0048] figure 2 and figure 1 The difference lies in the fact that a bonding layer 23 is interposed between the conductive layer 100 and the substrate 10 .

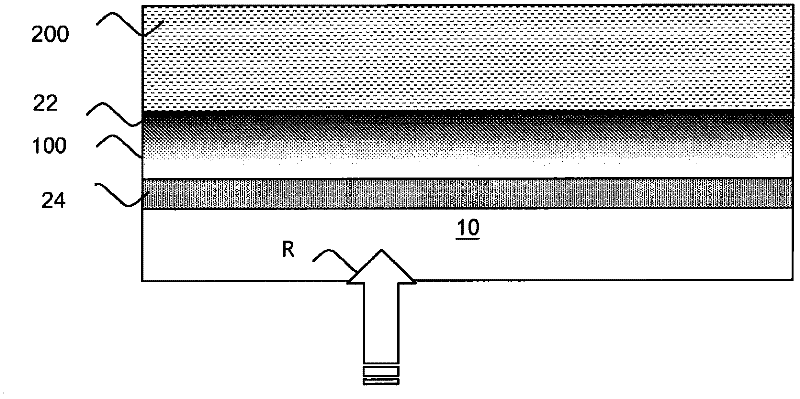

[0049] image 3 and figure 1 The difference lies in the fact that an alkali metal barrier layer 24 is interposed between the conductive layer 100 and the substrate 10 .

[0050] Figure 4 merged into figure 2 and image 3 The setup of the solution given in , incorporates the fac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com