Screw structure of double-screw extruder

A twin-screw extruder and twin-screw technology, applied in the protein composition of vegetable seeds, food science, protein food ingredients, etc., can solve the problems of protein denaturation, high production cost, complex process, etc., and achieve low fat content, The effect of full nutrition price and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] specific implementation plan

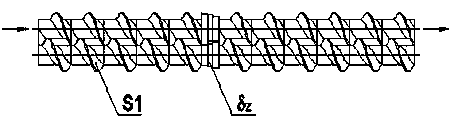

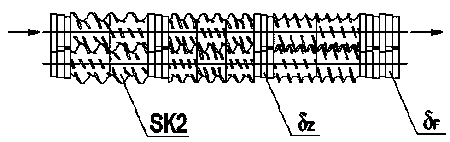

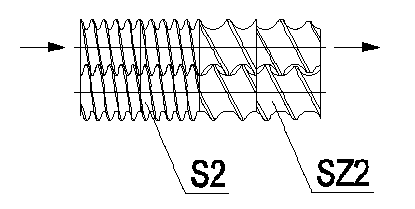

[0010] Such as figure 1 As shown, the present invention is a screw structure of a twin-screw extruder. The screw is a fully meshed co-rotating flat twin screw. The screw structure is composed of several thread elements and kneading blocks, and is divided into a conveying zone, a melting zone and a There are three functional areas in the metering homogenization area. Such as figure 2 As shown, the conveying area that guarantees the material filling factor and material premixing is composed of a single-head screw and a kneading block. Such as image 3 As shown, the melting zone consists of a kneading block and a grooved helix to increase mixing, homogenizing and shearing functions. Such as Figure 4 As shown, the metering and homogenizing zone to achieve quantitative and metering consists of a double-ended helix and a double-ended cone helix. Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the screw is composed of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com