Catalyst crushing and absorbing device of tubular reactor

A tubular reactor and catalyst technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of catalyst hardening, speeding up the unloading time, catalyst hardening and breaking, etc., so as to reduce the difficulty of unloading and speed up the unloading. time, the effect of shortening the removal time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

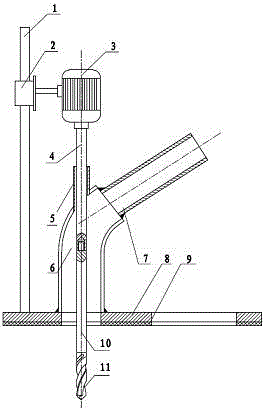

[0017] Embodiment 1: as figure 1 As shown, a catalyst crushing and unloading device for a tubular reactor, the device is supported by a base 8, the base 8 is provided with a base bend 6, one end of the base bend 6 communicates with the base 8, and at the mouth of the base bend 6 A suction nozzle 7 is arranged at the place, and the base elbow 6 and the suction nozzle 7 are sealed and connected; near the mouth of the base elbow 6, an extension rod fixing sleeve 5 for the passage of the electric mashing device is provided, and The electric crushing device and the extension rod fixing sleeve 5 are in a sealed state; the electric crushing device is fixed by the support rod 1 .

Embodiment 2

[0018] Embodiment 2: as figure 1 As shown, a tubular reactor catalyst crushing and unloading device, the device is supported by a base 8, the base 8 is provided with a base bend 6, the base bend 6 communicates with the base 8, and at the mouth of the base bend 6 A suction nozzle 7 is provided, the base elbow 6 and the suction nozzle 7 are fixedly connected by a gasket, and are in a sealed state, and an extension rod is provided at the nozzle close to the base elbow 6 for the passage of the electric mashing device The sleeve 5 is fixed, and the electric mashing device and the extension rod fixing sleeve 5 are in a sealed state; the electric mashing device is fixed by the support rod 1 .

[0019] Electric smashing device is made up of motor 3, the rod that links to each other with motor 3 and the drill bit 11 that is arranged on the rod top. The bar that links to each other with motor 3 is movable rod, and movable rod is extension rod 4,10, is to be connected by screw thread be...

Embodiment 3

[0020] Embodiment 3: as figure 1 Shown, a kind of tubular reactor catalyst crushing and unloading device, this device is supported by base 8, and this base 8 is provided with base elbow 6, and one end of base elbow 6 communicates with base 8, and at base elbow The other end of 6, that is, the mouth of the nozzle is provided with a suction nozzle 7, the base elbow 6 and the suction nozzle 7 are fixedly connected through a gasket, and are in a sealed state. The suction nozzle 7 is used to pass the vacuum suction machine through Pipeline is connected on the suction nozzle 7 of this device.

[0021] Near the mouth of the base elbow 6 is provided with an extension rod fixed sleeve 5 that can pass through the electric mashing device, and the electric mash device and the extension rod fixed sleeve 5 are in a sealed state; the electric mash device is powered by a motor 3. The rod connected with the motor 3 is composed of the drill bit 11 arranged on the top of the rod. The bar that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com