Multi-trough integral stretching die for stainless steel troughs

A technology of stainless steel and mould, which is applied in the field of multi-groove overall stretching moulds, which can solve the problems that the depth of the main groove cannot be too large, the first stretching rate cannot be too small, and it is easy to break, so as to reduce the tension. Stretch scrap rate, reasonable and practical structure, easy stretch forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

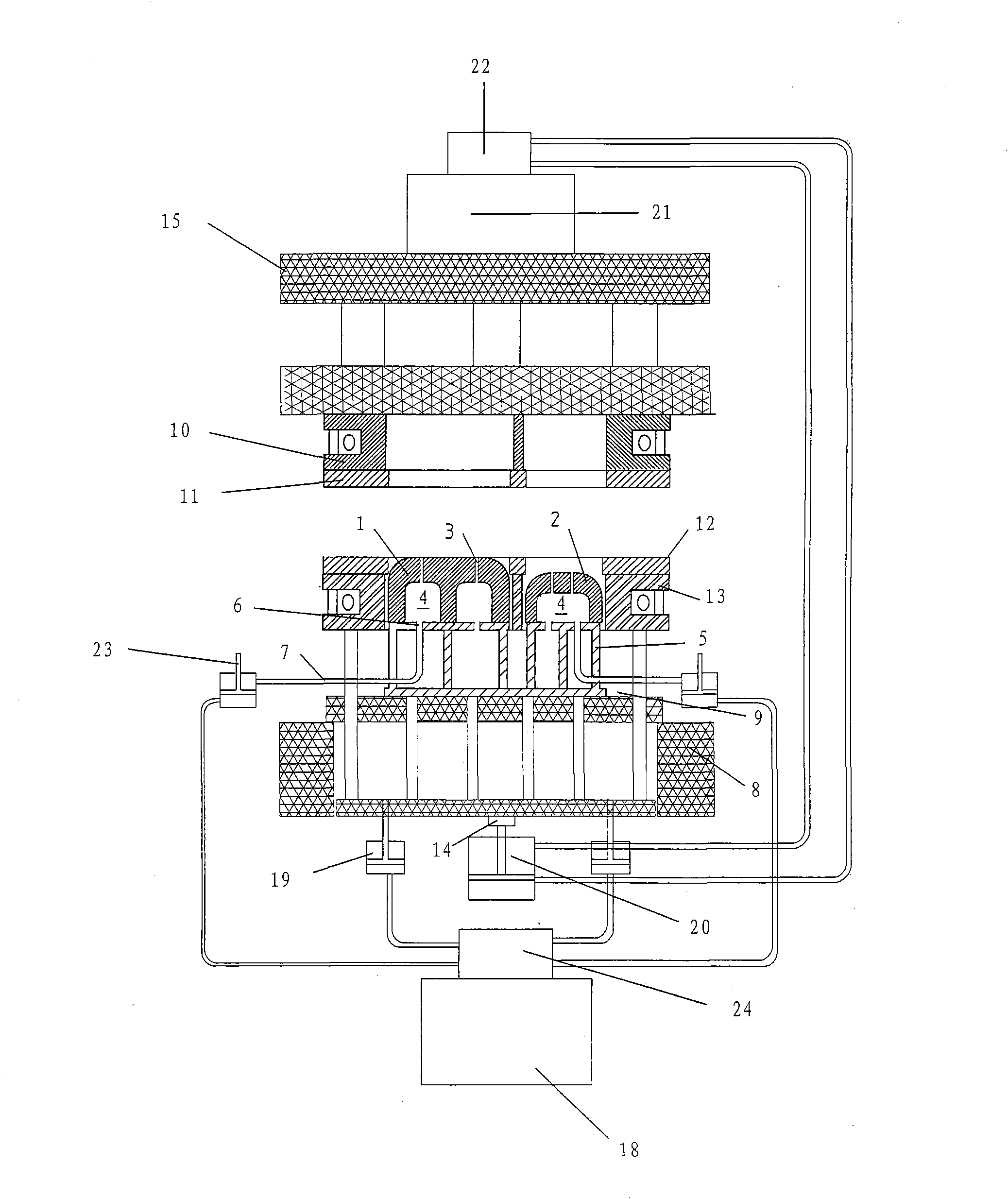

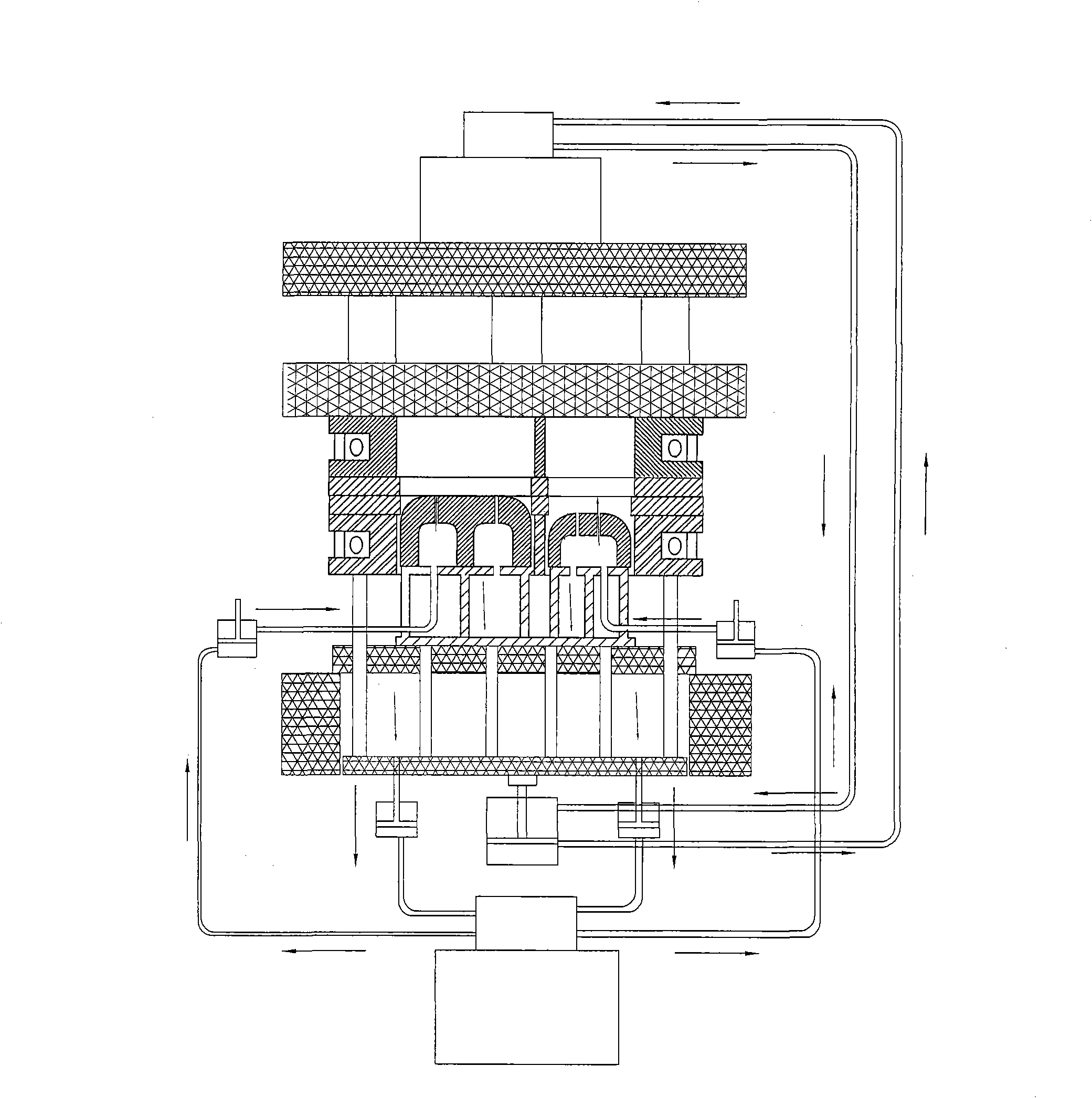

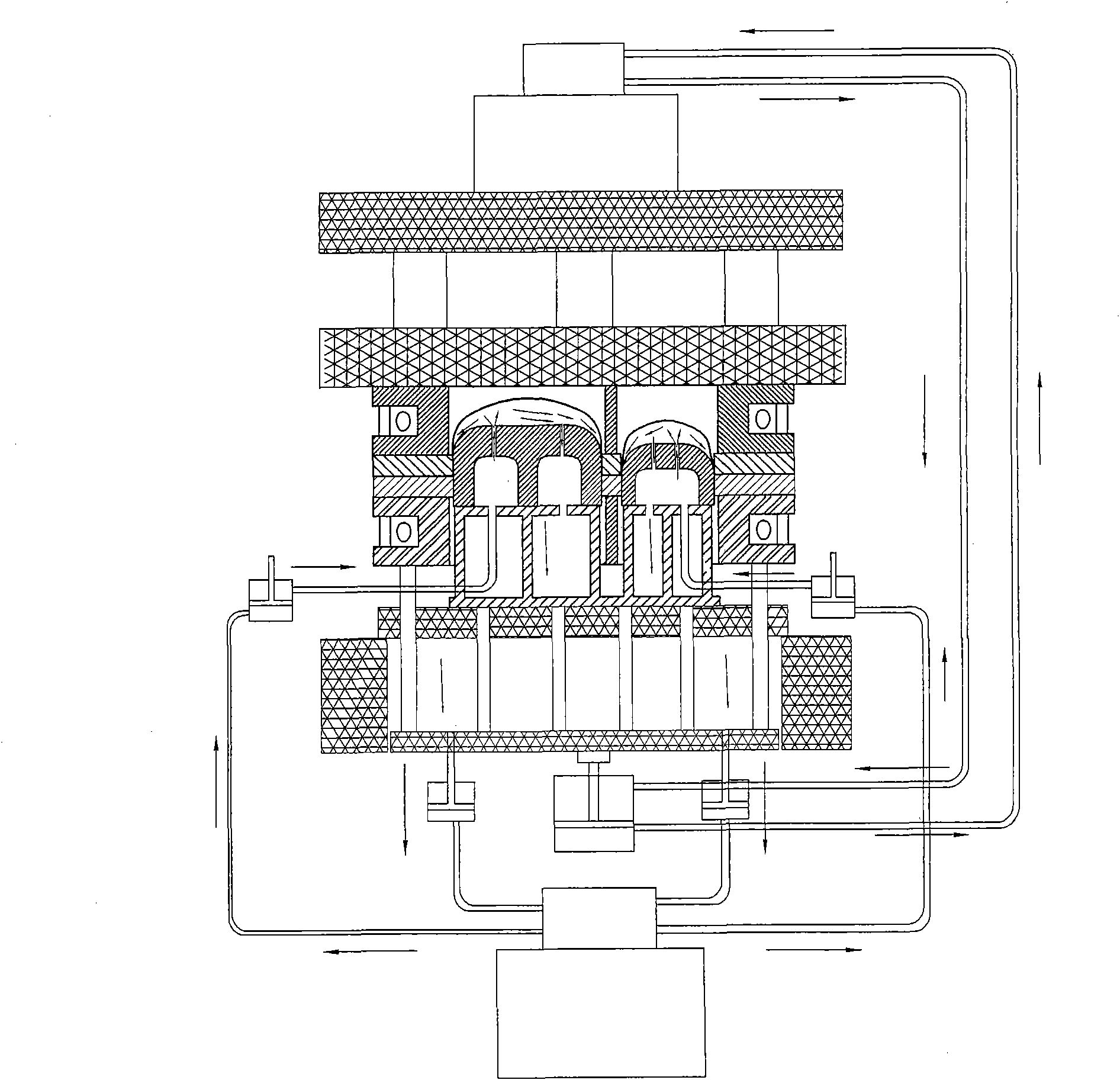

[0039] Such as Figure 1 to Figure 6 Shown, a kind of stainless steel sink multi-groove overall stretching mold, it comprises: the first mold that is used for the first stretching, the second mold that is used for the second stretching, the working table that cooperates, these and The traditional molds are similar, and the key point of the invention is that on the main punch 1 and the sub-punch 2 of the first mold, there are oil injection holes 3 at the top positions used to form the cavity, and the oil injection The hole 3 is arranged on the top of the main punch 1 and the top of the sub-punch 2 for forming each cavity, and the oil injection hole 3 communicates with the cavity 4 in the respective punch, and the bottom surface of each cavity 4 is connected to the mold frame. 5 fit, through the through hole 6 opened on the upper panel of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com