Suspension unit structure of maglev train

A maglev train and unit structure technology, applied in electric vehicles, vehicle components, electric traction, etc., can solve problems such as increasing the manufacturing, installation and maintenance costs of guide rails and beams, increasing the difficulty of controller design, and affecting the stability of the suspension system. , to reduce design difficulty, improve dynamic characteristics, and facilitate production and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

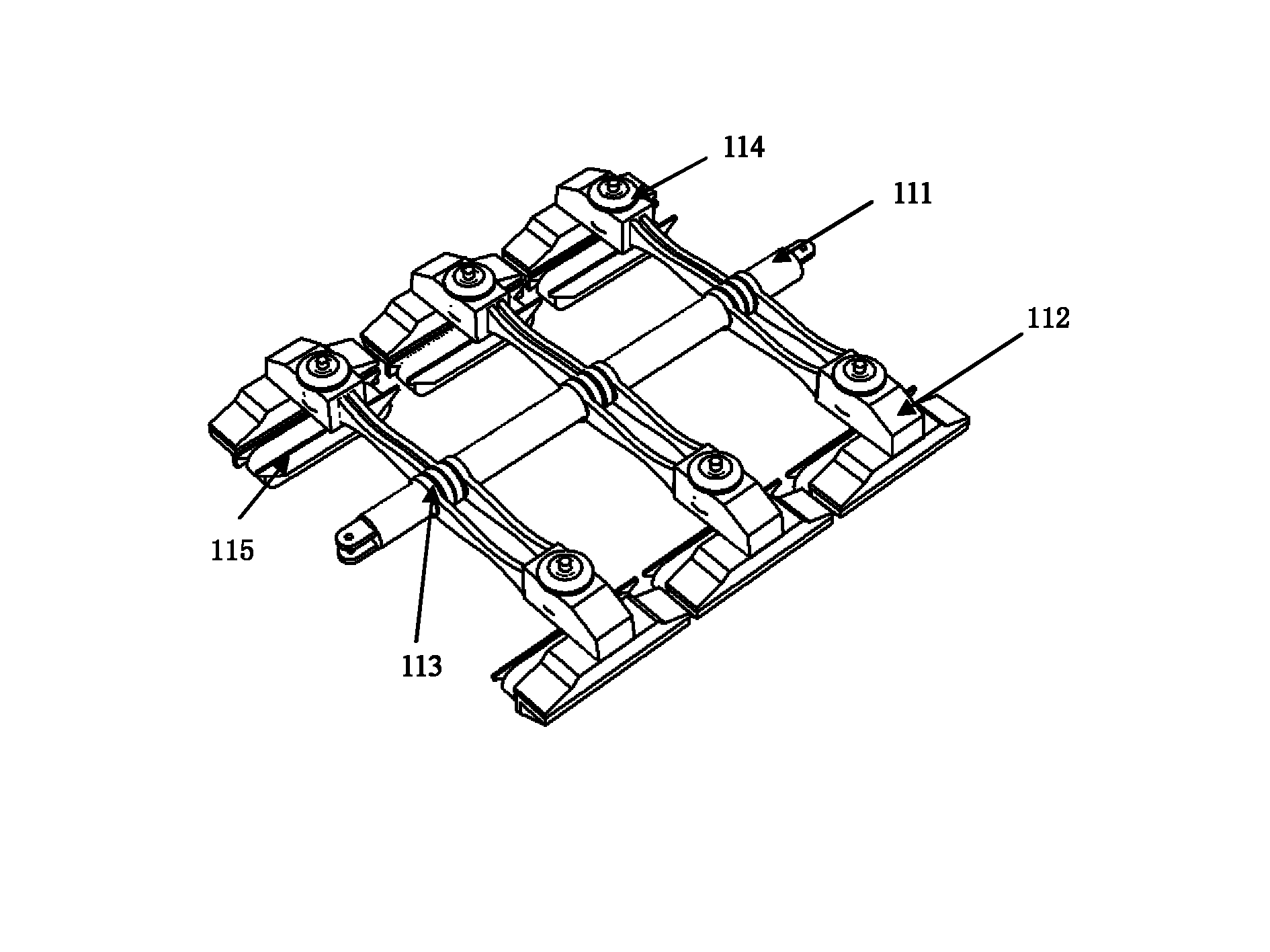

[0014] exist image 3 Middle: the suspension frame has a longitudinal support beam 111 fixed in the middle of the car body of the maglev train. One end of the suspension guide module is sleeved on the support beam 111 through the bearing 113, and the suspension guide modules are symmetrically arranged on both sides of the longitudinal support beam in pairs. The suspension guide module is composed of a transverse support 112 and an electromagnet 115 arranged at one end of the transverse support. The suspension guide module is provided with an air spring 114 for coupling with the vehicle body.

[0015] In one bogie unit, at least two pairs of suspension guide modules are sleeved on the longitudinal support beam 111 . In this embodiment, three pairs of suspension guide modules are socketed as an example.

[0016] What is stated above is only the preferred implementation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com