Powder charging and discharging device

A technology for feeding and discharging materials and powders, applied in transportation and packaging, conveying bulk materials, conveyors, etc., can solve the problems of high price, poor performance, complex structure, etc., and achieve the effect of low cost, reliable performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

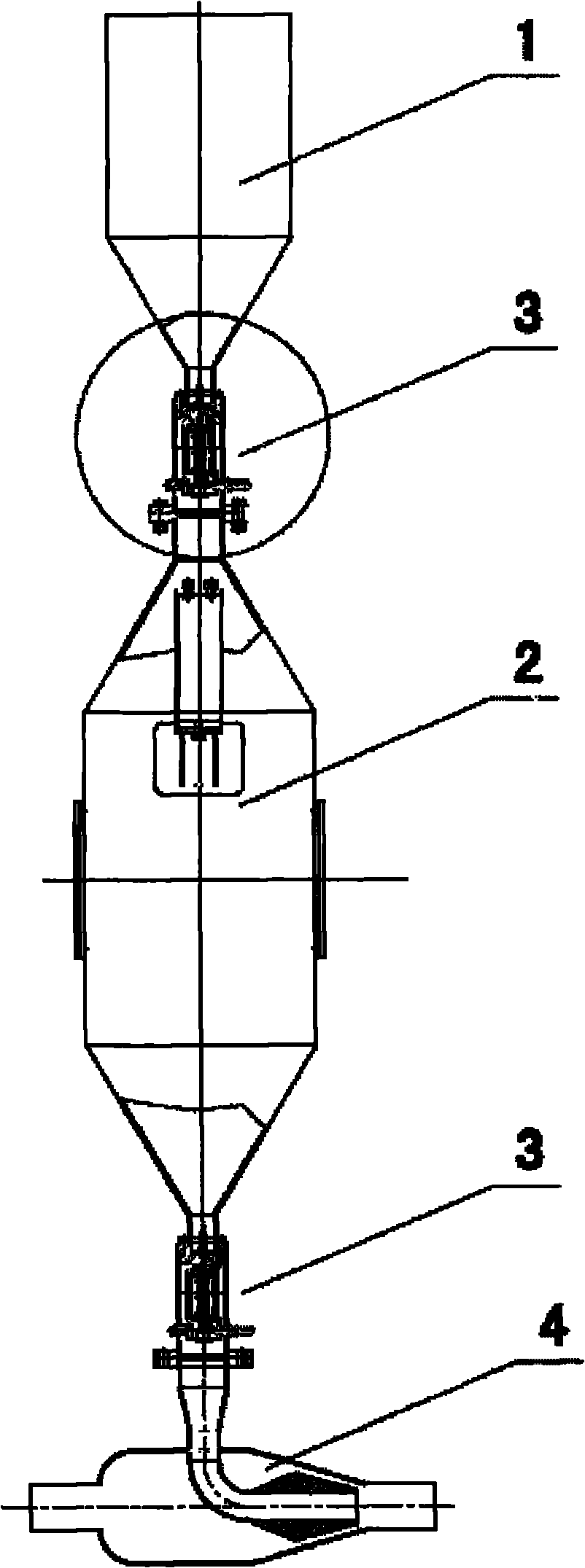

[0017] The powder feeding and discharging device of the present invention comprises a feed hopper 1, a storage chamber 2, a Venturi tube 4 and a control valve 3, the feed hopper 1 and the storage chamber 2 are connected through a control valve 3, the storage chamber 2 and the The Venturi tube 4 is also connected through a control valve 3 .

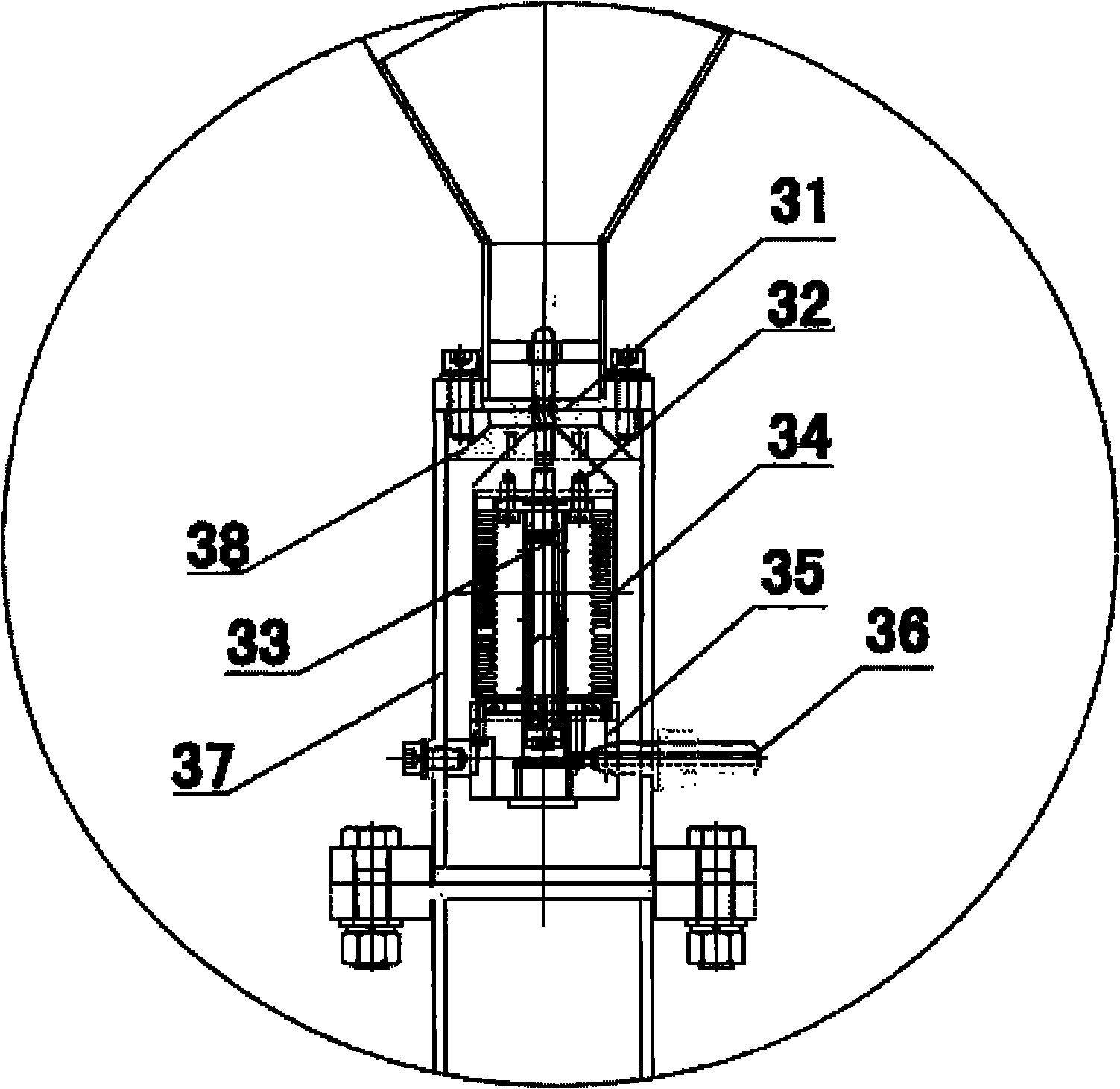

[0018] Preferably, the control valve 3 includes a valve body 37, a truncated conical shoulder 38 disposed in the valve body 37, a conical valve seat 31 that is engaged with the shoulder 38 and can slide up and down along the axis of the control valve, A tapered spool 32 arranged below the valve seat 31 and capable of sliding up and down along the axis of the control valve and a base plate 35 arranged below the spool 32 and fixed in the valve body 37 , the spool 32 passes through at least one spring 33 It is connected to the base plate 35 with at least one bellows 34 , and an air pipe 36 communicating with the bellows 34 is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com