Construction method for treating foundation through filling by adopting draining pile tubes

A construction method and technology of drainage piles, applied in basic structure engineering, soil protection, construction, etc., can solve problems such as complex construction process, high construction cost, waste of materials, etc., to simplify construction process, save construction cost, and shorten construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

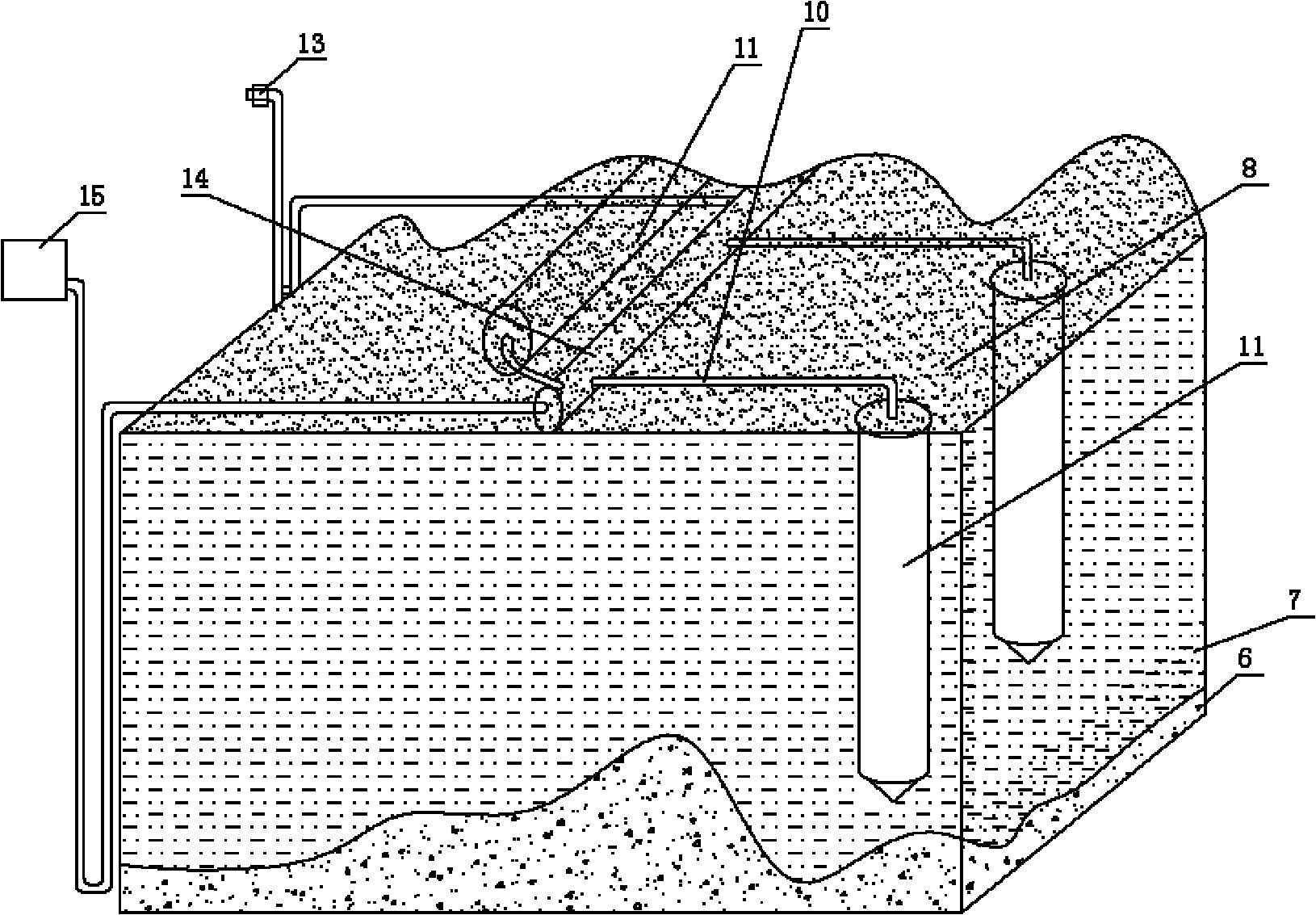

[0031] Embodiment 1, the construction method of using the drainage pile pipe filling method to treat the foundation includes the following steps:

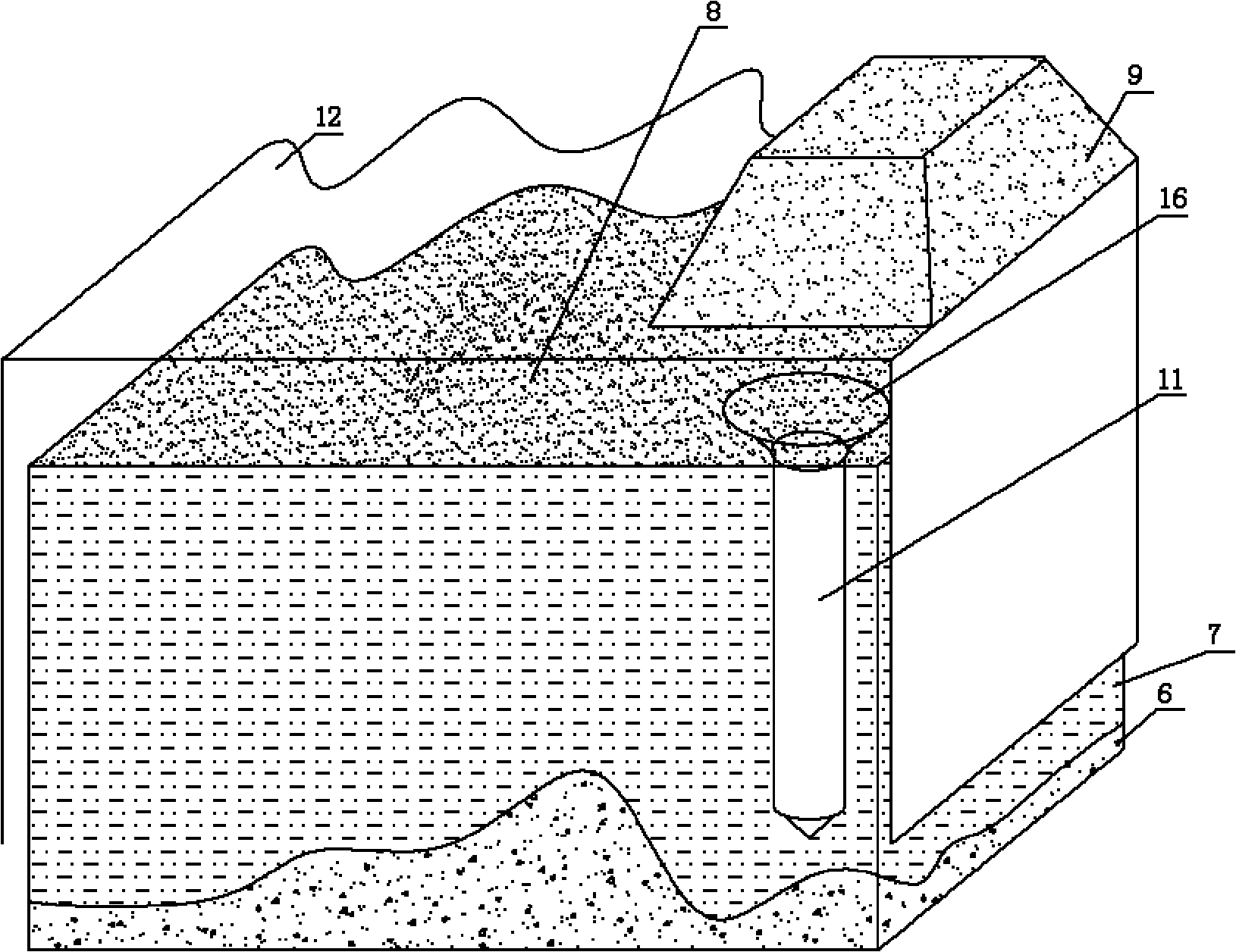

[0032] The first step is to clean the surface of the foundation and lay a horizontal drainage cushion 8 (building materials with good water permeability such as gravel, gravel, sand, etc.);

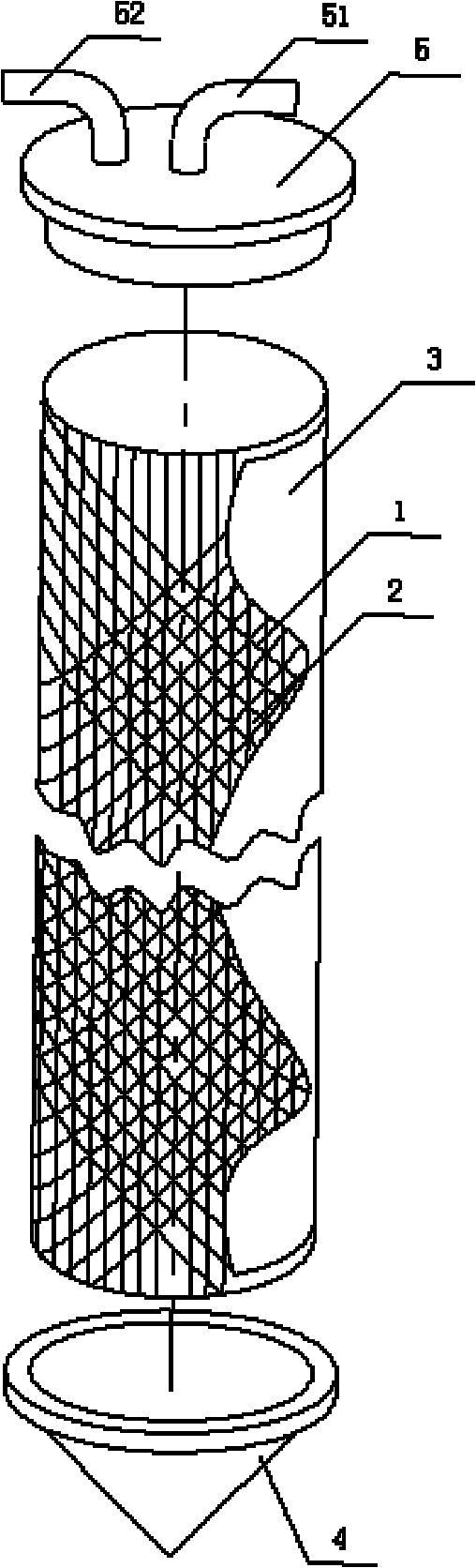

[0033] The second step is to use a drainage pile pipe with holes in the pipe wall and a filter membrane, install the bottom plug 4 of the drainage pile pipe, and insert the buried drainage pile pipe 11 according to the depth and spacing required by the project;

[0034] The 3rd step, insert and place hollow plastics pumping drainage pipe 10 (preferably inserted into the bottom position of drainage pile pipe) in every drainage pile pipe;

[0035] The fourth step is to connect each plastic pumping and draining pipe to the connection pipe 14 to form an interconnected pipe network, and connect the connection pipe to the suction water pump 15 on th...

Embodiment 2

[0043] Embodiment 2, the construction method of using the drainage pile pipe filling type to treat the foundation includes the following steps:

[0044] The first step is to clean up the surface of the foundation;

[0045] The second step is to use a drainage pile pipe with holes in the pipe wall and a filter membrane, install the bottom plug 4 of the drainage pile pipe, and insert the buried drainage pile pipe 11 according to the depth and spacing required by the project;

[0046] The 3rd step, insert and place hollow plastics pumping drainage pipe 10 (preferably inserted into the bottom position of drainage pile pipe) in every drainage pile pipe;

[0047]The fourth step is to connect each plastic pumping and draining pipe to the connection pipe 14 to form an interconnected pipe network, and connect the connection pipe to the suction water pump 15 on the ground;

[0048] The fifth step is to use the water pump for continuous pumping and drainage, and discharge the accumulate...

Embodiment 3

[0054] Embodiment three, the construction method of using the drainage pile pipe filling type to treat the foundation includes the following steps:

[0055] The first step is to clean the surface of the foundation, laying a horizontal drainage cushion 8 (drainage materials with good water permeability such as gravel, gravel, sand, etc.), and laying a plastic drainage filter pipe in the horizontal drainage cushion;

[0056] The second step is to use a drainage pile pipe with holes in the pipe wall and coated with a filter membrane, install the bottom plug 4 of the drainage pile pipe, and insert the buried drainage pile pipe 11 according to the depth and spacing required by the project;

[0057] The third step is to insert a hollow pumping drainage pipe 10 (preferably inserted into the bottom position of the drainage pile pipe) in each drainage pile pipe, install the special sealing top plug 5 for the drainage pile pipe, the suction and drainage pipe mouth joint 51 and the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com