Improved structure of fixed type louver blade outer frame

An improved structure, fixed technology, applied in special equipment for doors/windows, windows/doors, building components, etc., can solve the problems of affecting functions, bending and deformation of outer frame blades, inconvenient construction and use, etc., to facilitate drainage. , Avoid extrusion damage, improve the effect of waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiment of the improved structure of the fixed window blade outer frame of the present invention will be described in detail below with reference to the accompanying drawings. However, the present invention is not limited to the following examples.

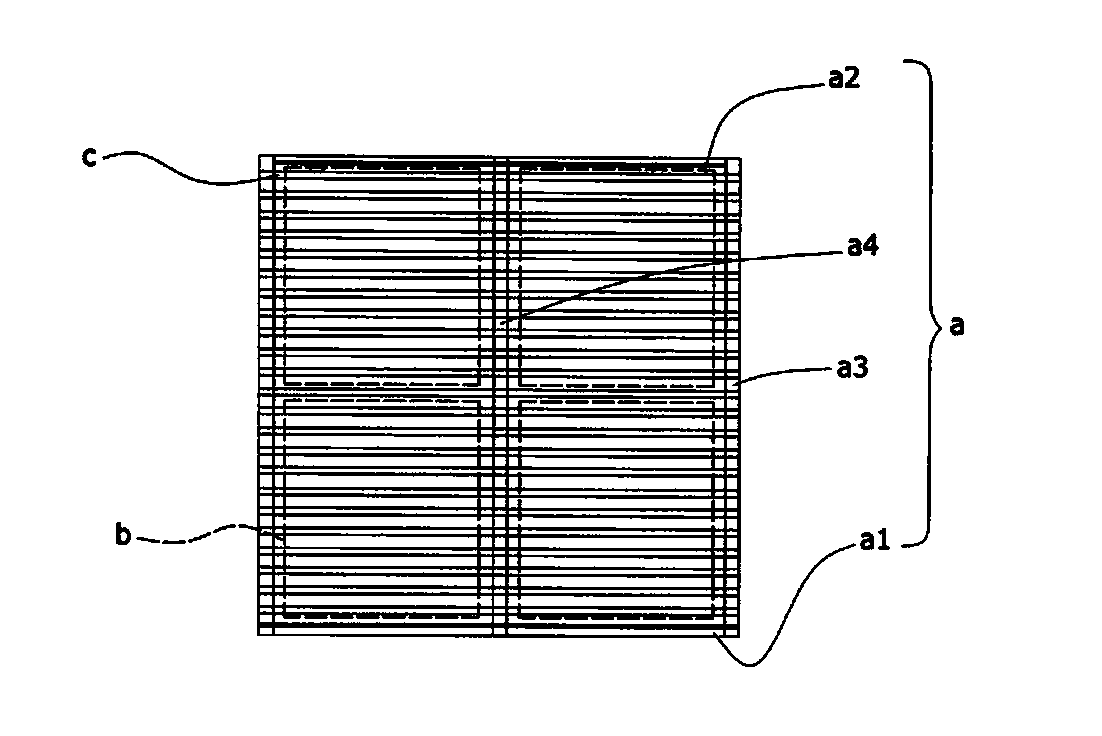

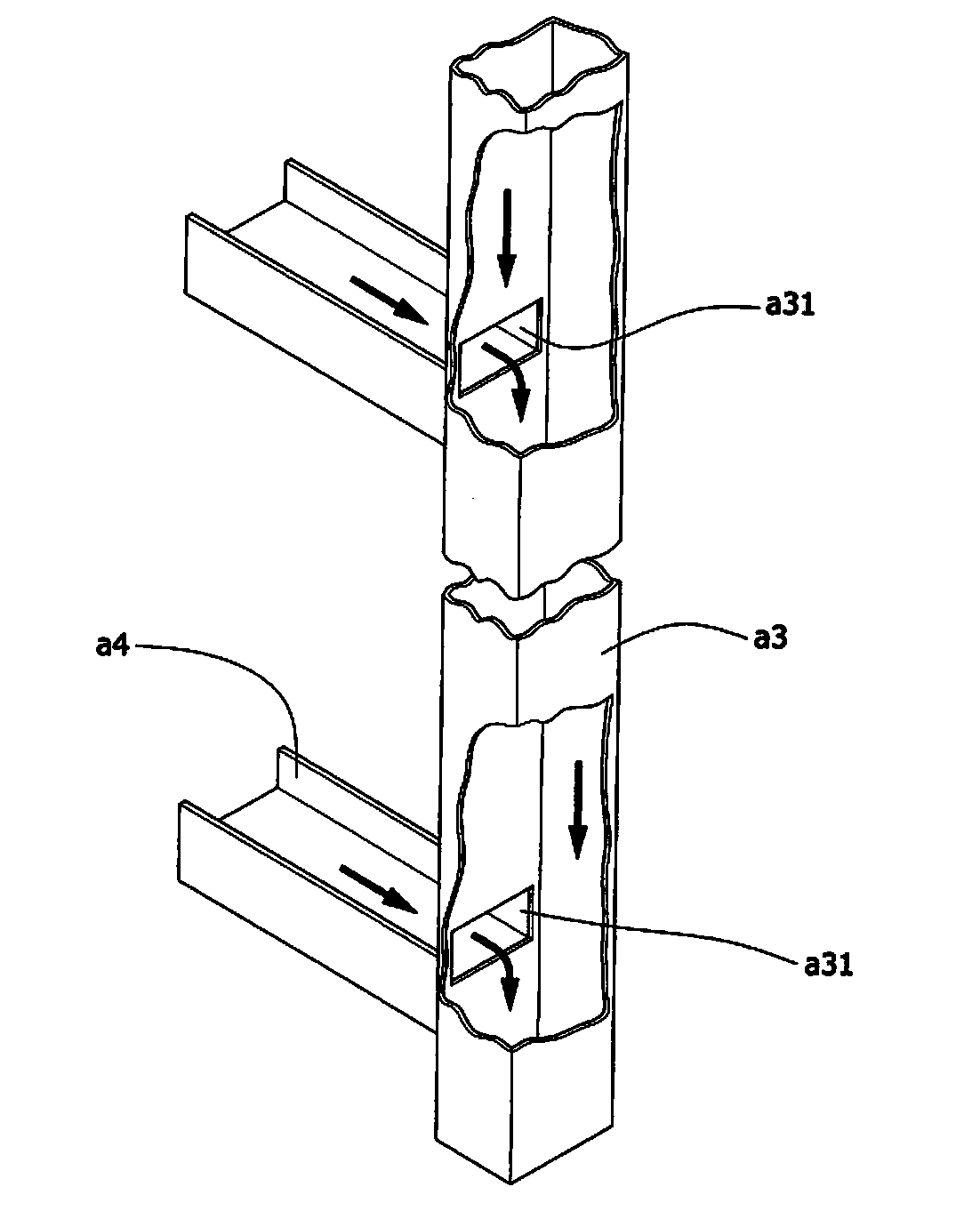

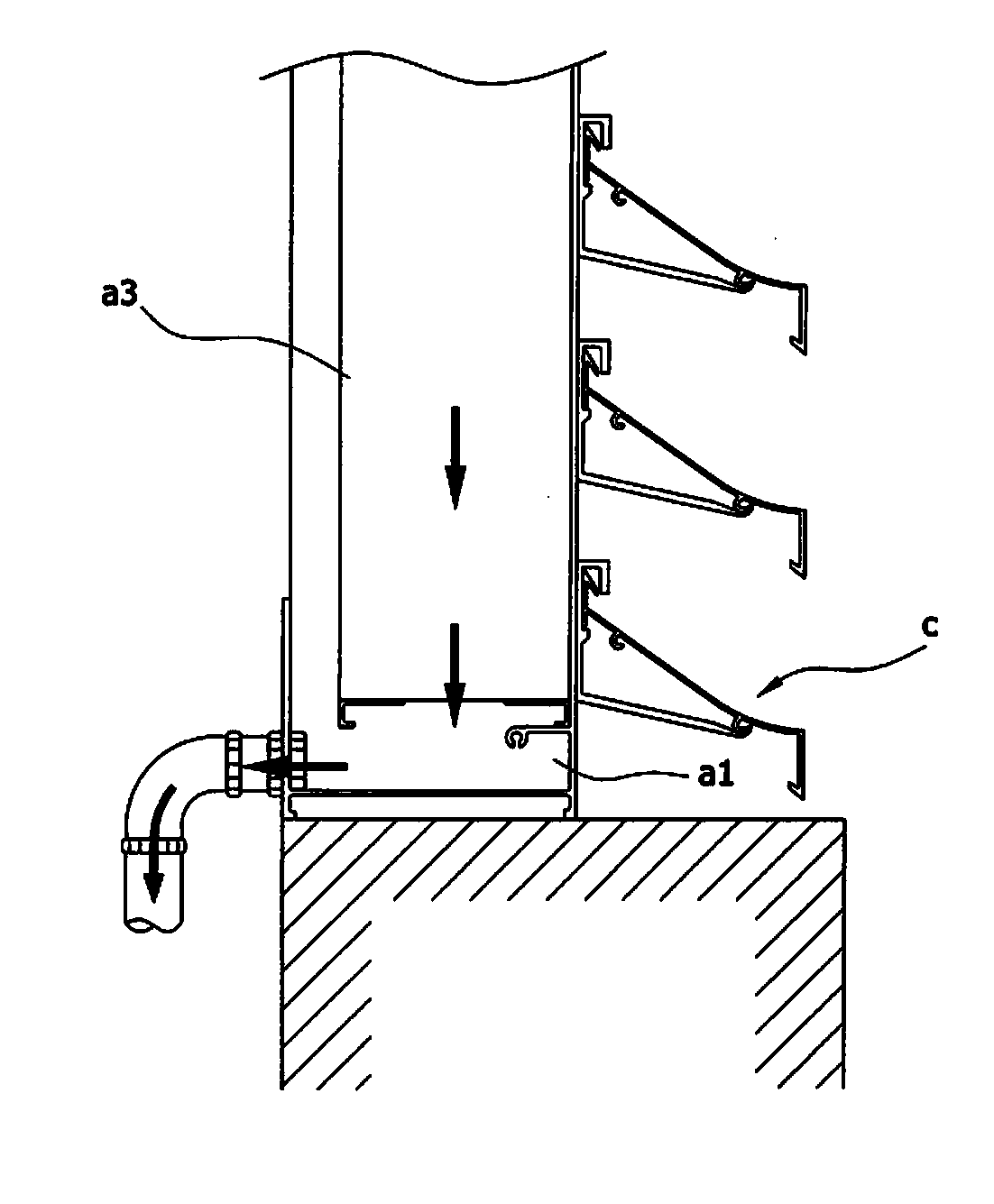

[0033]An improved structure of the outer frame of a fixed window leaf according to the present invention includes a set of fixed window leaves 10, a set of outer frames 20, a plurality of water baffles 30 and a plurality of fixing seats 40, the group of outer frames and The group of fixed window blades is matched and connected on the peripheral surface of the group of fixed window blades, the group of fixed window blades includes a plurality of blades 11 and a pair of inner frames 12, and the plurality of blades are sequentially arranged at intervals Between the pair of inner frames; the group of outer frames includes an upper outer frame 21, a lower outer frame 22, and a pair of upright outer frames 23, and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com