Equipment for construction of bridge floor waterproof layer

A waterproof layer and equipment technology, applied in bridge construction, bridges, erection/assembly of bridges, etc., can solve the problems of water accumulation, reduced functional effect of concrete protective layer, different degrees of concrete compaction, etc., to meet the vertical and horizontal drainage slope, High construction efficiency and good drainage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

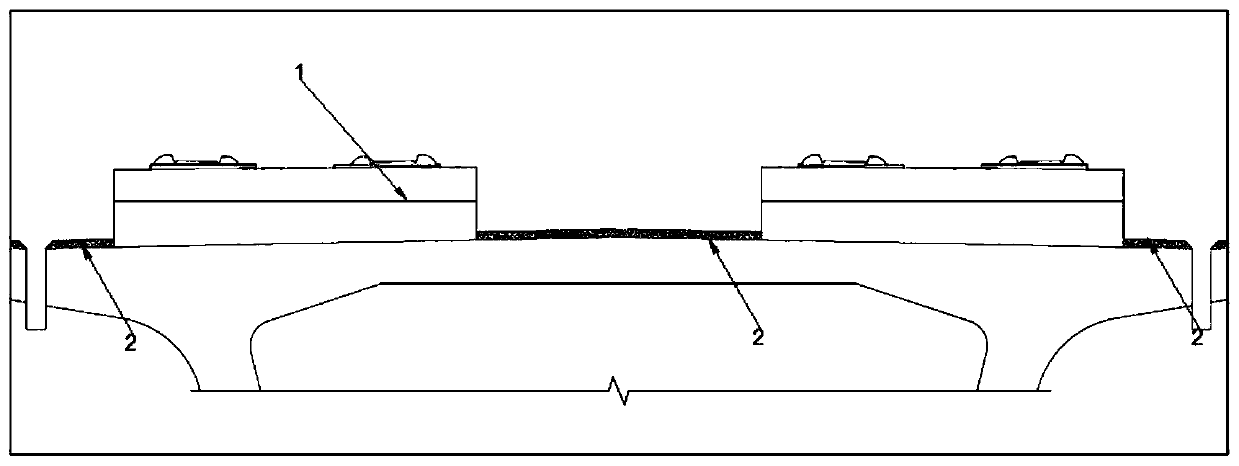

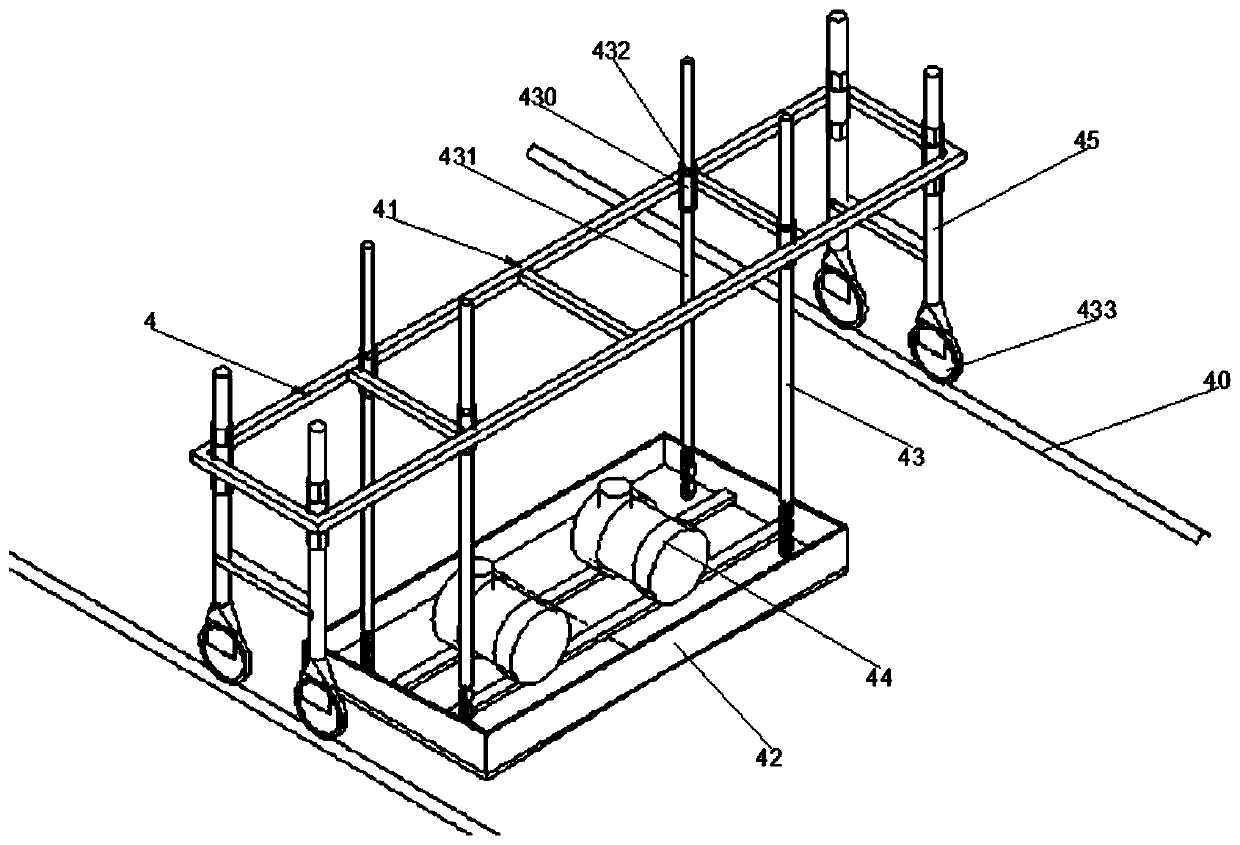

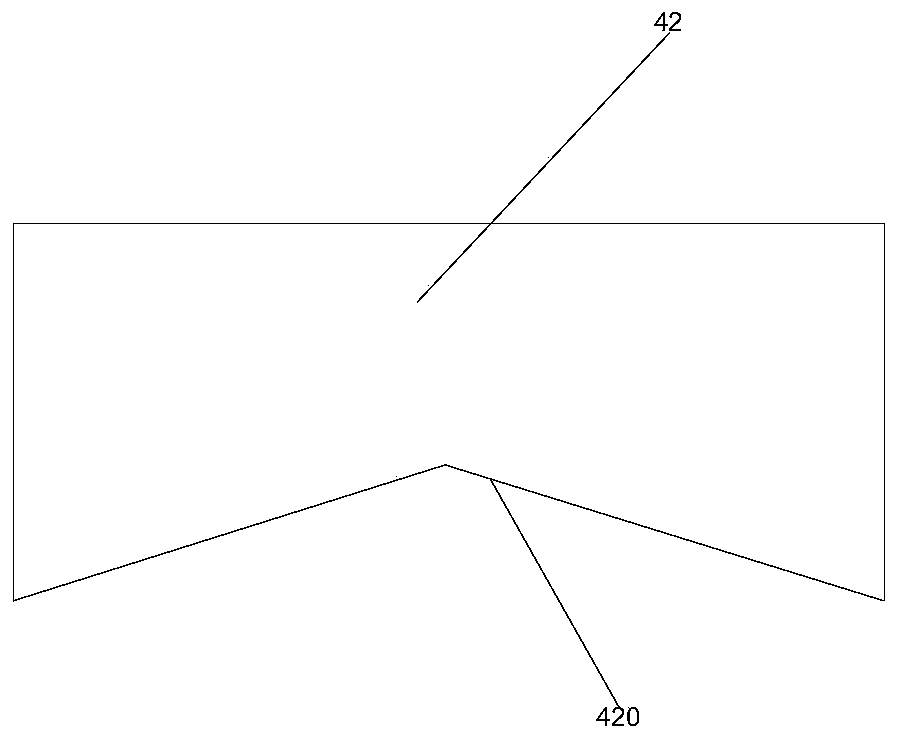

[0046] see figure 1 As shown, the embodiment of the present invention provides a kind of equipment for the construction of bridge deck waterproof layer, which is used for the bridge deck 2 between two adjacent rows of ballastless tracks 1 and the bridge between the ballastless track 1 and the protective wall. Surface 2 is used for construction, the asphalt coil 7 is first laid, and then concrete is poured on the asphalt coil 7 to form a waterproof layer. After the concrete is poured, the concrete vibrating device 4 is used to vibrate the concrete and close the surface, see figure 2 As shown, the concrete vibrating device 4 includes two slide rails 40, a support frame 41, a vibrating table 42 and a driver 44. When the bridge deck 2 between two adjacent rows of ballastless tracks 1 is constructed, the two slide rails The rail 40 is set on two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com