Method for measuring wall thickness of downhole casing

A casing wall and thickness measurement technology, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., to eliminate the influence of cement sheath on the counting rate of detectors and improve the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

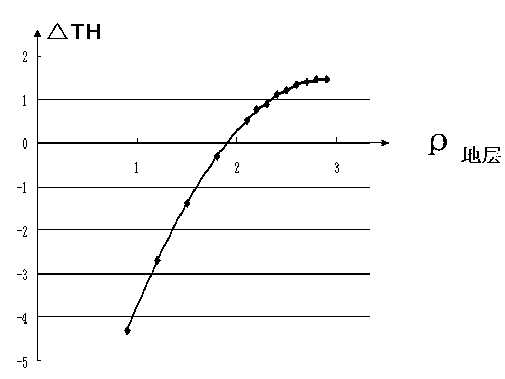

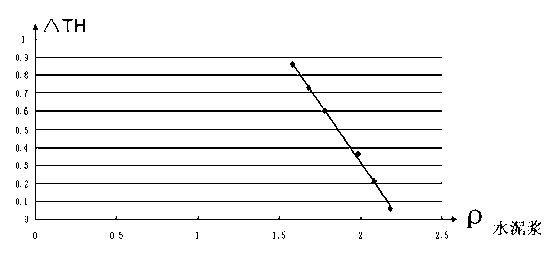

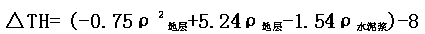

[0021] A downhole casing wall thickness measurement method, according to the counting rate curve of the far and near detectors, eliminate the influence of formation density and cement sheath density on the casing wall thickness calculation value, and use the regression method to establish a casing wall thickness calculation formula to calculate Casing wall thickness.

[0022] The specific process is as follows:

[0023] ①According to the near detector count rate (TL) and the far detector count rate (PL), the regression method is used to establish the calculation method of casing wall thickness:

[0024] TH=TH ST - K*LN(TL / TL ST )+LN(PL / PL ST )+△TH

[0025] In the above formula, TH is the calculated wall thickness value, TH ST is the standard casing wall thickness, K is the scale coefficient, TL is the near detector count rate value, TL ST is the average counting rate value of the standard well section, PL is the far detector counting rate value, PL ST is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com