Solar tracking control direction angle driving system

A solar tracking and driving system technology, applied in the direction of using feedback control, etc., can solve the problems of weak impact resistance, short service life, small transmission torque, etc., and achieve the effect of improving service life, small cumulative error and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

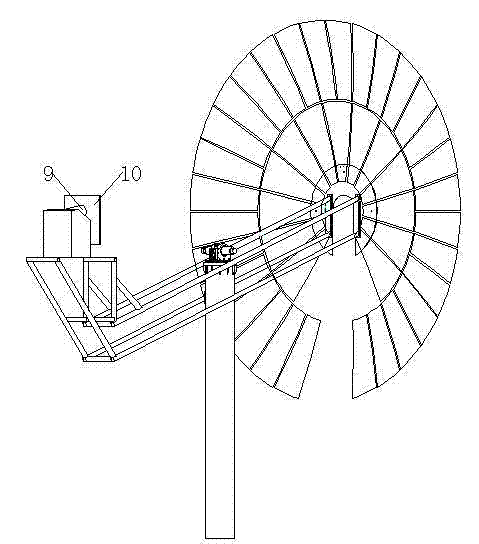

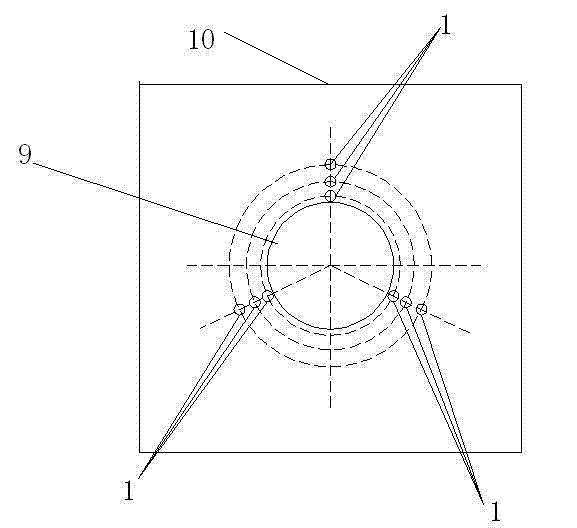

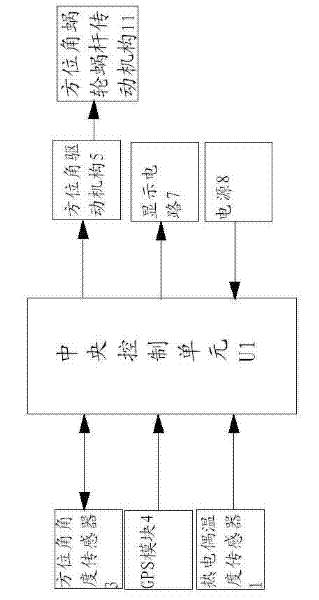

[0019] like Figure 1~4 As shown, a solar tracking control azimuth drive system includes a receiver 9, a protective plate 10, at least three thermocouple temperature sensors 1, a central control unit U1, an azimuth angle sensor 3, an azimuth drive mechanism 5, and a GPS module 4. Power supply 8, azimuth worm gear 11, direction rotation platform 13 and direction rotation shaft 15; the thermocouple temperature sensor 1, azimuth angle sensor 3 and GPS module 4 are all electrically connected to the central control unit U1, so The thermocouple temperature sensor 1 transmits a temperature signal to the central control unit U1, the azimuth angle sensor 3 transmits an azimuth signal to the central control unit U1, the GPS module 4 transmits the solar coordinates to the central control unit U1, and the azimuth angle The drive mechanism 5 is electrically connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com