Multi-channel LED current equalization drive circuit

A technology of drive circuit and rectifier circuit, which is applied in the direction of electric lamp circuit layout, electric light source, lighting device, etc., can solve the problems affecting the application, increasing the difficulty of control, affecting the steady-state gain of the converter, etc., and achieve the effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

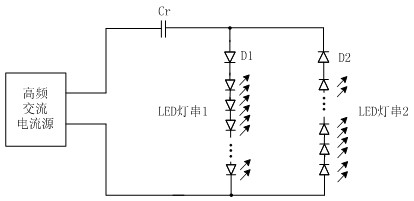

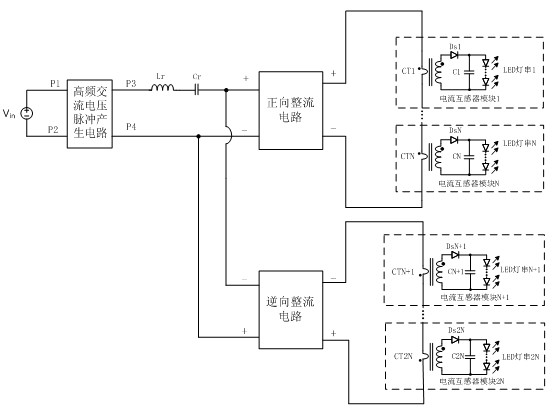

[0038] Figure 5 It is the first specific embodiment of the present invention, including a high-frequency AC voltage pulse generating circuit, an inductor Lr, a capacitor Cr, a diode D1, a diode D2 and 2N current transformer drive modules. Diode D1 and diode D2 respectively constitute a forward rectification circuit and a reverse rectification circuit, belonging to a half-wave rectification circuit; one output terminal of the high-frequency AC voltage pulse generating circuit is connected to one end of the inductor Lr, and the other end of the inductor Lr is connected to one end of the capacitor Cr , the other end of the capacitor Cr is connected to the anode of the diode D1 and the cathode of the diode D2, the cathode of the diode D1 is connected to the end of the primary winding of the current transformer 1, and the primary windings of the current transformer 1 to the current transformer N are connected in sequence from the beginning to the end. connected, the opposite end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com