Method for pretreating plant starting material for the production, from sacchariferous and lignocellulosic resources, of bioethanol and/or of sugar, and plant

A bioethanol and pretreatment technology, applied in fiber raw material treatment, cellulose raw material pulping, sugar production, etc., can solve the problems of low annual utilization rate of sugar making and brewery equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

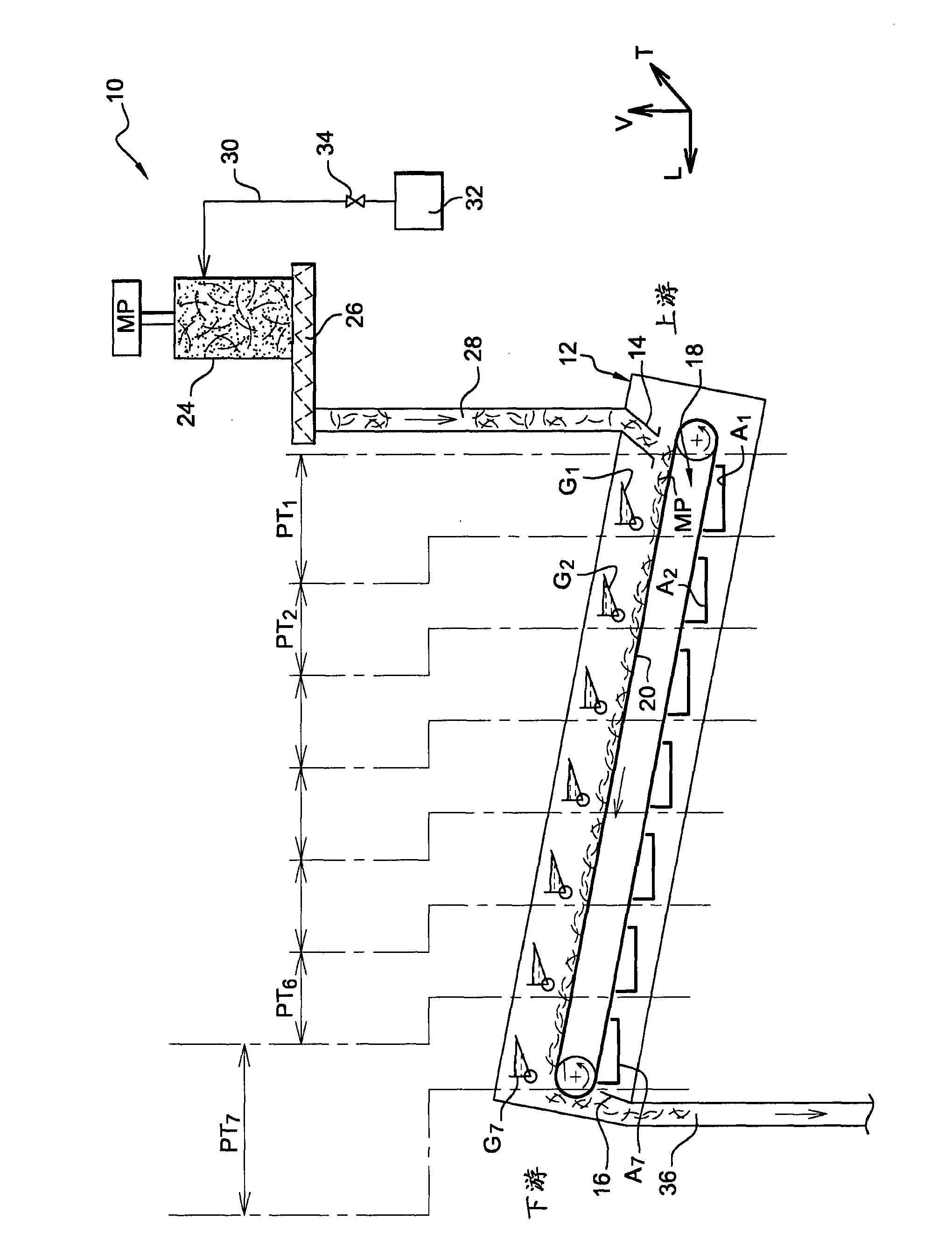

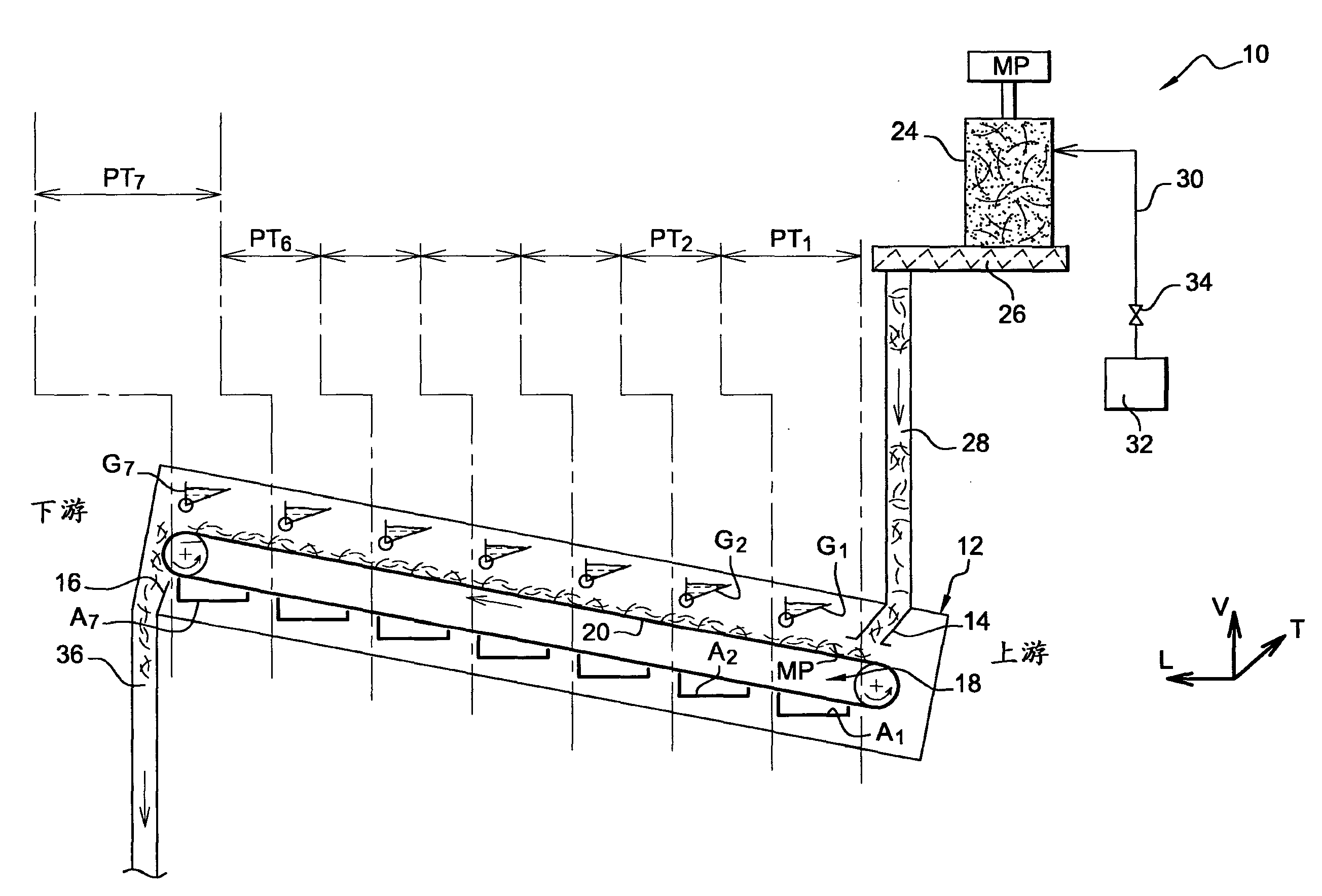

[0035] In the following specification, all the same, similar or analogous elements and components will be denoted by the same reference numerals.

[0036] The terms "longitudinal", "vertical" and "transverse" are used with respect to the three dimensions (trihedron) L, V, T illustrated on the figures.

[0037] The upstream-downstream orientation will also be used for the longitudinal flow of common indoor plant material, from right to left, referring to the accompanying drawings, along the L axis.

[0038] The apparatus 10 schematically illustrated in FIG. 1 comprises a pretreatment chamber 12 which is of the general shape of a longitudinally oriented and substantially horizontal parallelepipedal chamber, for example with the direction shown in FIG. 1 from downstream to upstream. slight inclination.

[0039] The pretreatment chamber 12 is sealed to prevent any acid vapor from escaping into the atmosphere when acid is used in the process of the present invention.

[0040] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com