Method for turning counterbores at two ends

A processing method and counterbore technology, which is applied in the processing field with counterbore at both ends, and can solve the problem that the coaxiality of counterbore on both ends cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with embodiment.

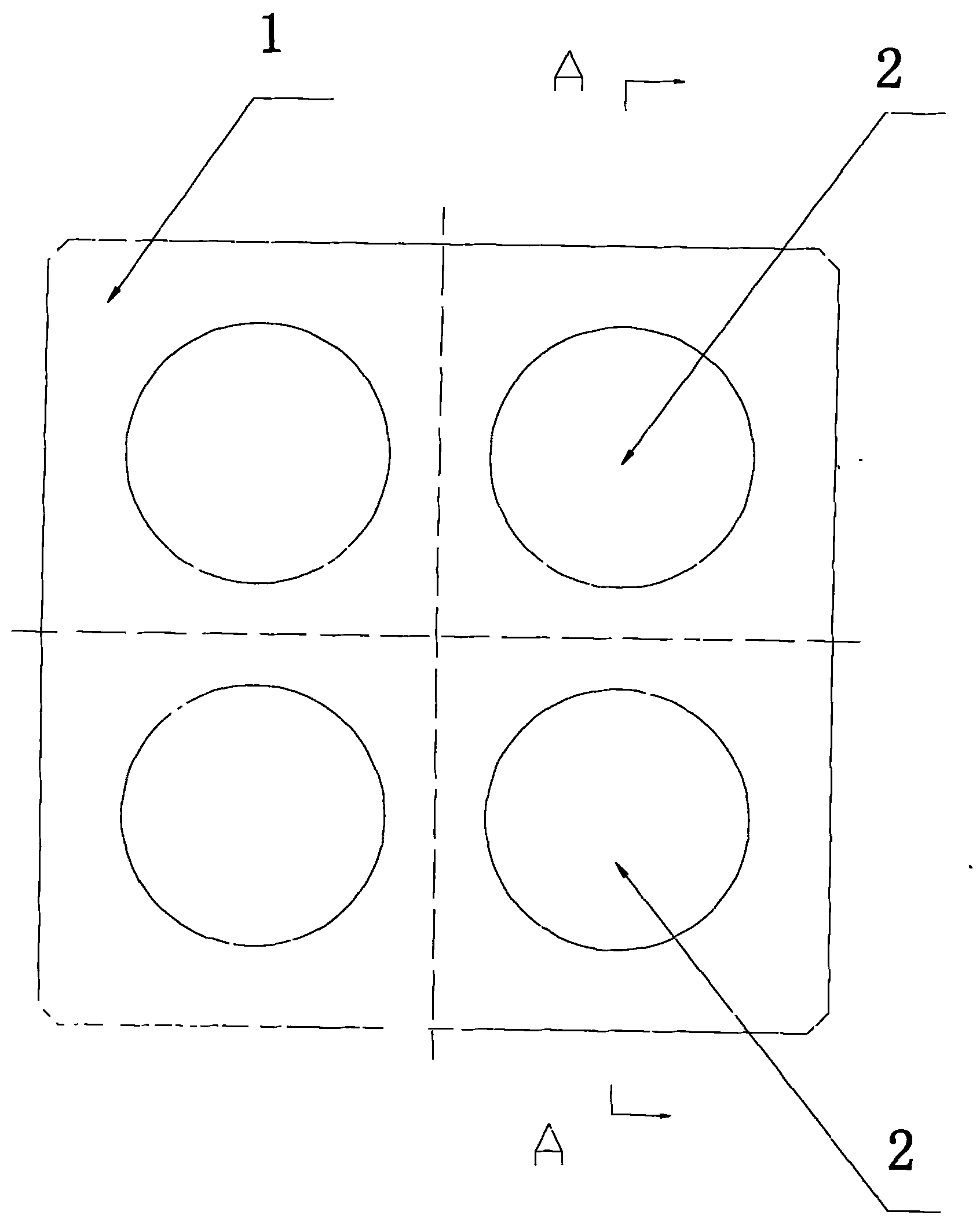

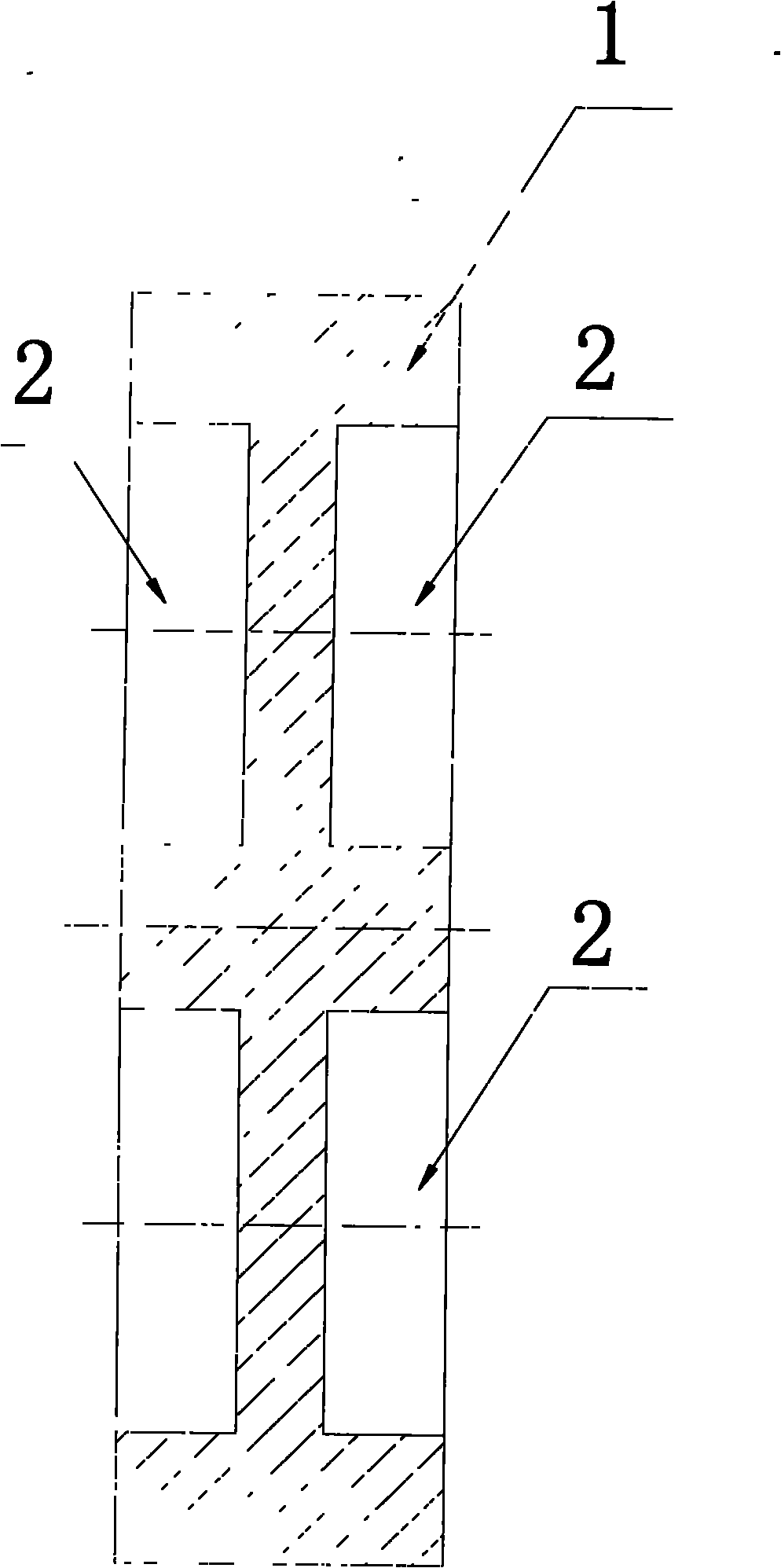

[0016] like figure 1 , 2 As shown, a part 1 to be processed has two end faces, and each end face is processed with four counterbores 2. It is required that the corresponding counterbores 2 on both sides of the end face should be on the same axis. The processing steps are as follows:

[0017] 1: According to the requirements of the drawings, blank, plan, mark, drill small holes, and drill the center hole for part 1. Use the top 5 of the lathe to withstand the center hole, and clamp it with the four-jaw chuck 6 at the same time, and the other end of the part is countersunk. 2;

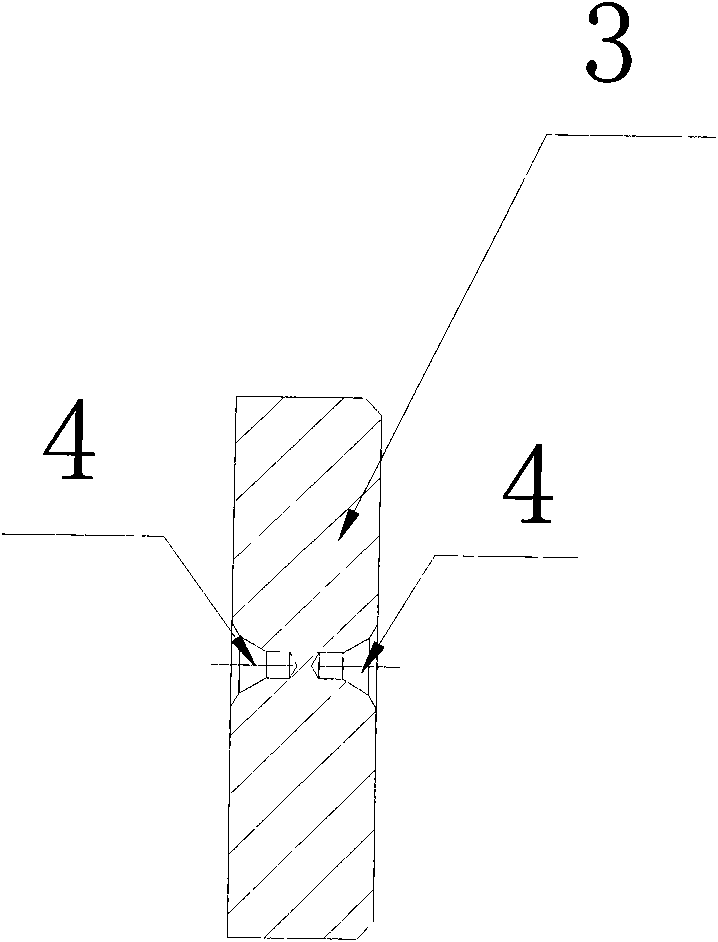

[0018] 2: Processing tooling such as image 3 As shown, the two ends of the tooling are milled out, and the center hole 4 is drilled at the same time. The outer circle of the tooling 3 is processed with the two center holes 4 at the top of the lathe. The diameter match;

[0019] 3. If Figure 4 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com