Ultraprecise free-form surface turning method of actively counteracting errors

An ultra-precision, motion error technology, applied in automatic control devices, metal processing mechanical parts, metal processing, etc., can solve the problems of poor surface quality and low processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

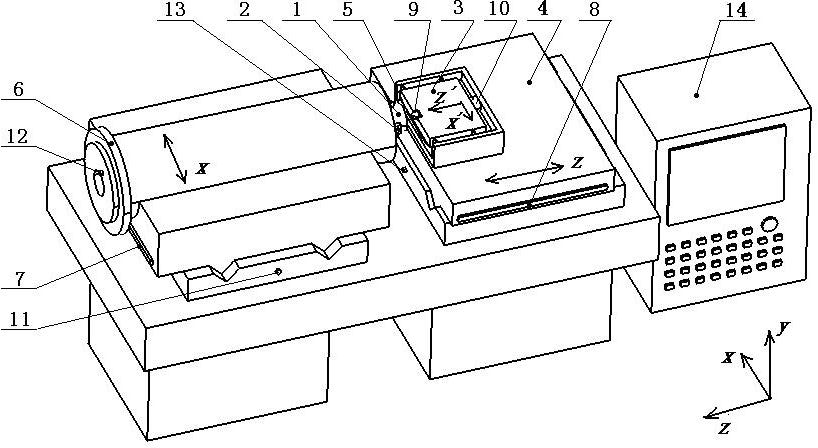

[0043] Such as figure 1 As shown, the workpiece 1 is installed on the fixture 2 at the front end of the spindle of a two-axis ultra-precision CNC lathe, and a two-degree-of-freedom FTS device 3 is installed on On the shaft carriage 4, the diamond tool 5 is clamped on the two-degree-of-freedom FTS device 3, and the ultra-precision CNC lathe axis and The shafts are in a "T" configuration. A high-precision rotary grating 6 is installed at the end of the spindle to detect the spindle rotary pulse, high-precision Axis linear grating 7, 8 axis linear gratings are used to detect axis with Coordinate position of axes, high resolution Displacement sensor 9, Displacement sensors 10 are used to detect FTS devices respectively with The reciprocating motion of the shaft, the temperature sensors 11, 12, 13 are installed on the ultra-precision CNC lathe to detect temperature changes, and these detection signals are fed into a high-performance multi-axis motion controller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com