Automatic bag supplier for valve bag

A valve pocket, automatic technology, applied in packaging and other directions, can solve the problems of high input manpower, low efficiency, and high labor intensity of workers, and achieve the effect of reducing labor intensity, improving filling efficiency, and reducing labor input.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

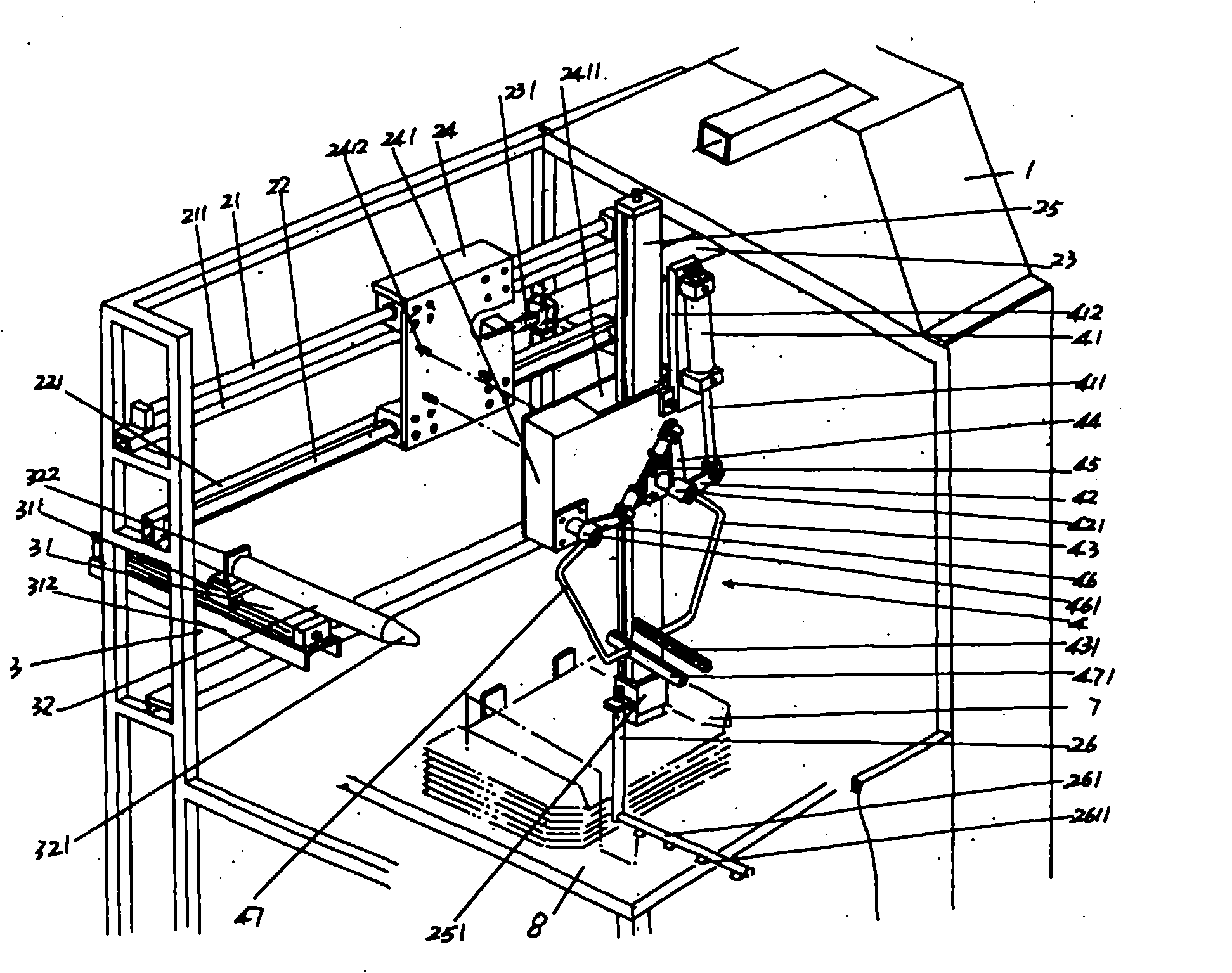

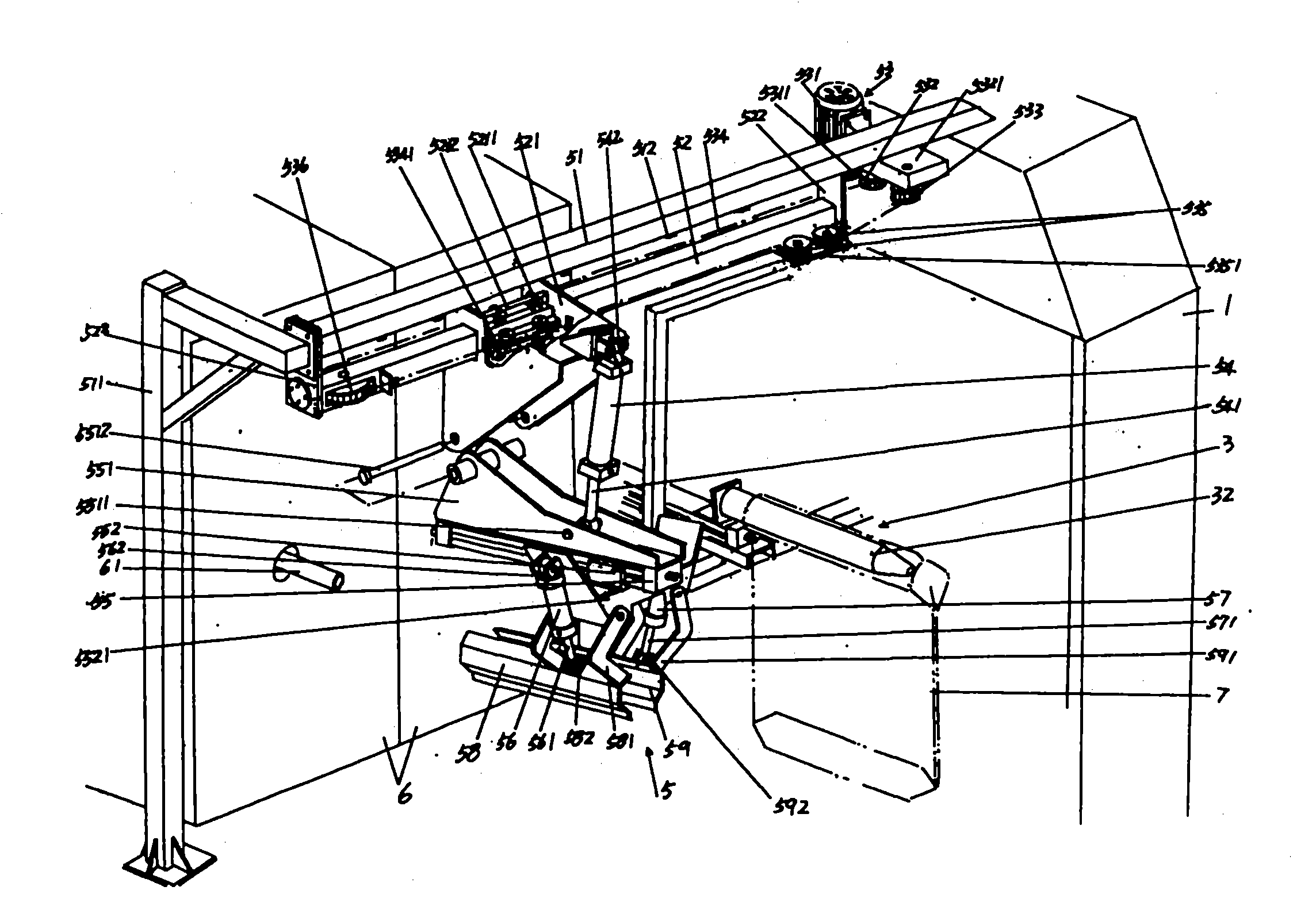

[0022] In order to enable the public to fully understand the technical essence and beneficial effects of the present invention, the applicant will describe in detail the specific implementation of the present invention below in conjunction with the accompanying drawings, but the applicant's description of the embodiments is not a limitation to the technical solution. Changes in the form of the inventive concept rather than in substance should be regarded as the protection scope of the present invention.

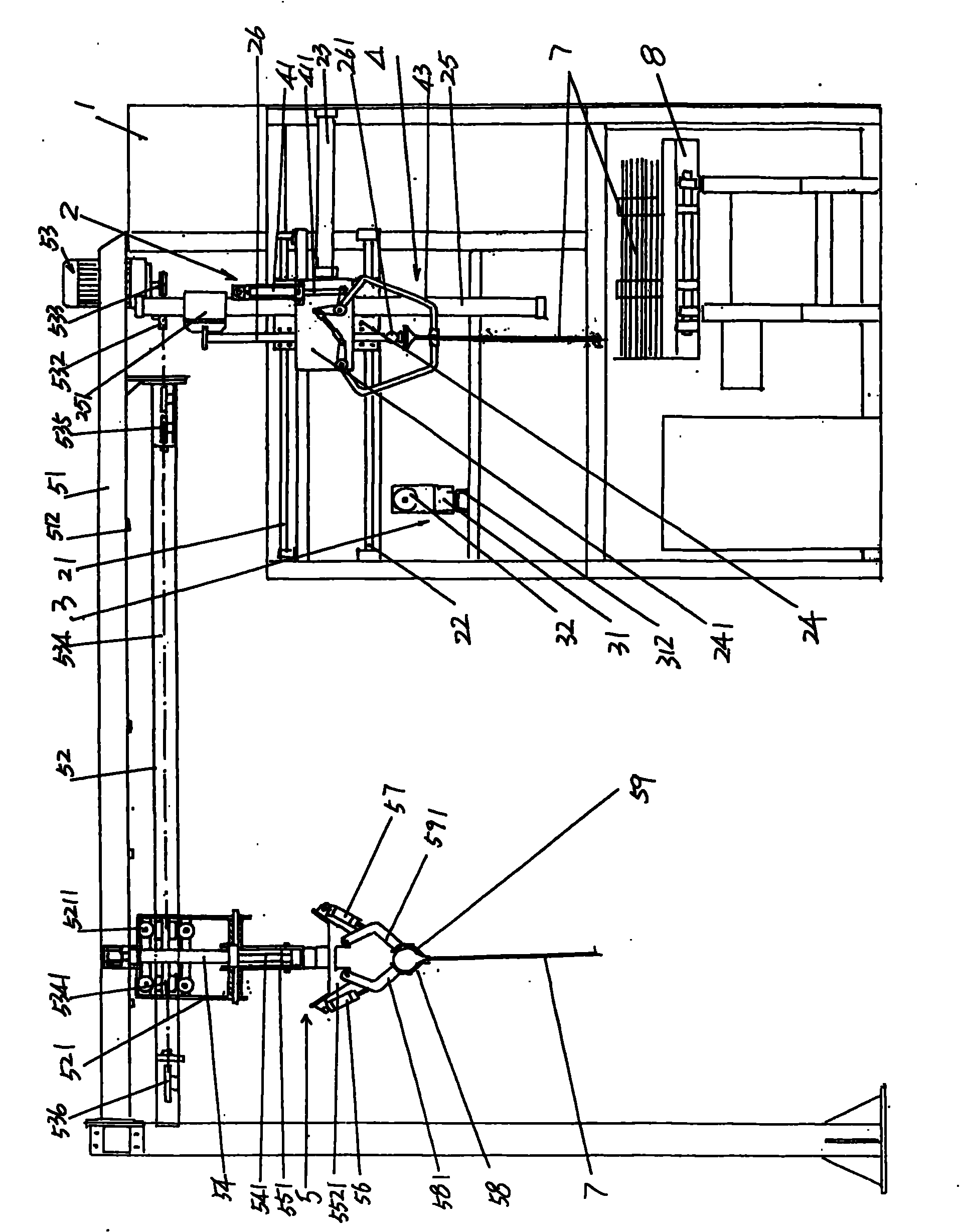

[0023] please see figure 1 , a frame 1 is shown in the figure, and the frame 1 is undoubtedly configured in at least two filling machines 6 each having a horizontal filling port 61 arranged in line with each other in a state of use. One side, and corresponds to the front of the horizontal filling mouth 61, which can be obtained by image 3 The indication was confirmed, image 3Although two filling machines 6 each having a horizontal filling port 61 are illustrated, they are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com