Inside and outside general bridge girder erection machine for high speed railway tunnel and girder erecting technology thereof

A technology for high-speed railways and bridge erection machines, which can be used in the erection/assembly of bridges, bridges, bridge construction, etc., and can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The specific implementation of the present invention will be further described in conjunction with examples (with drawings):

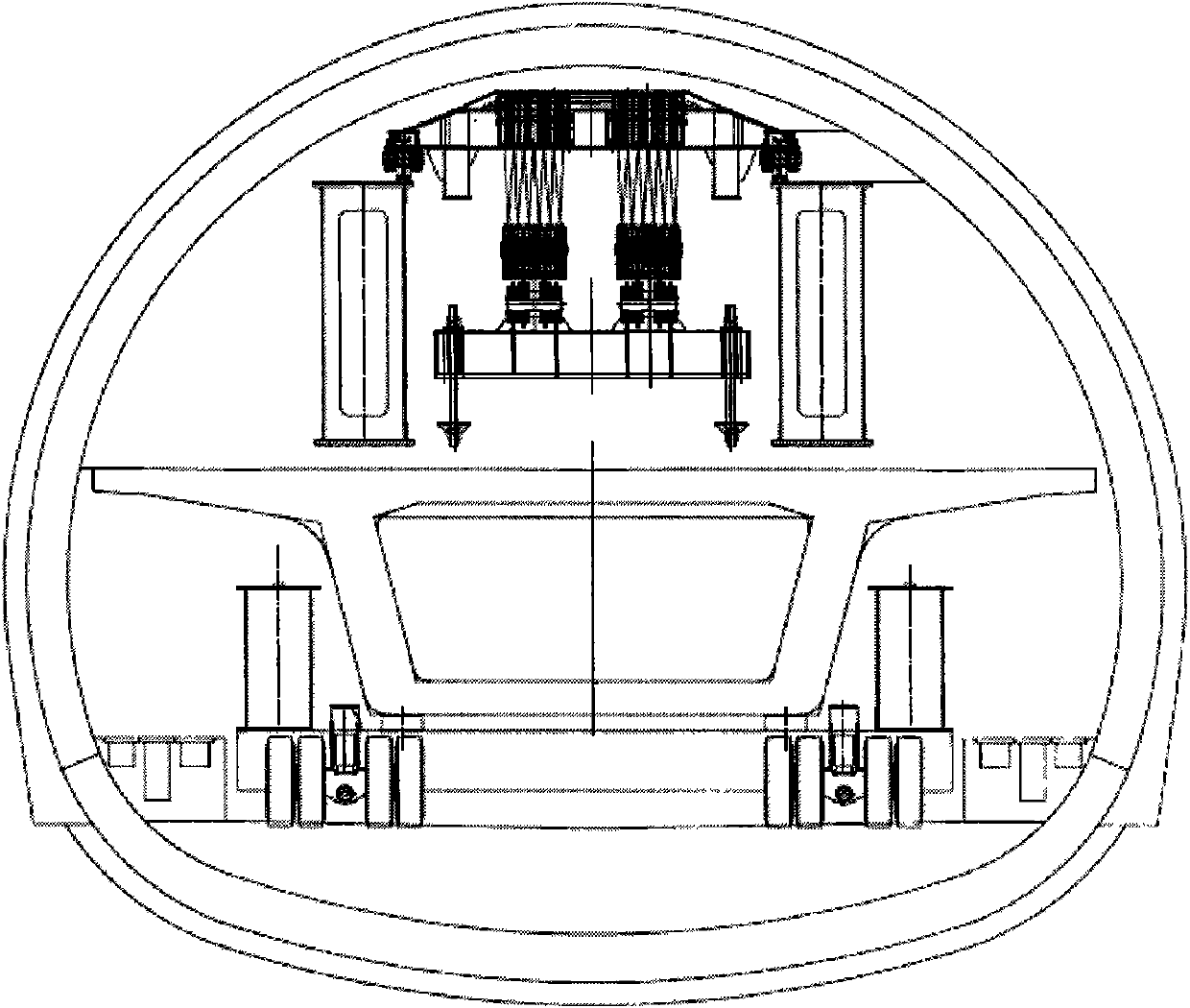

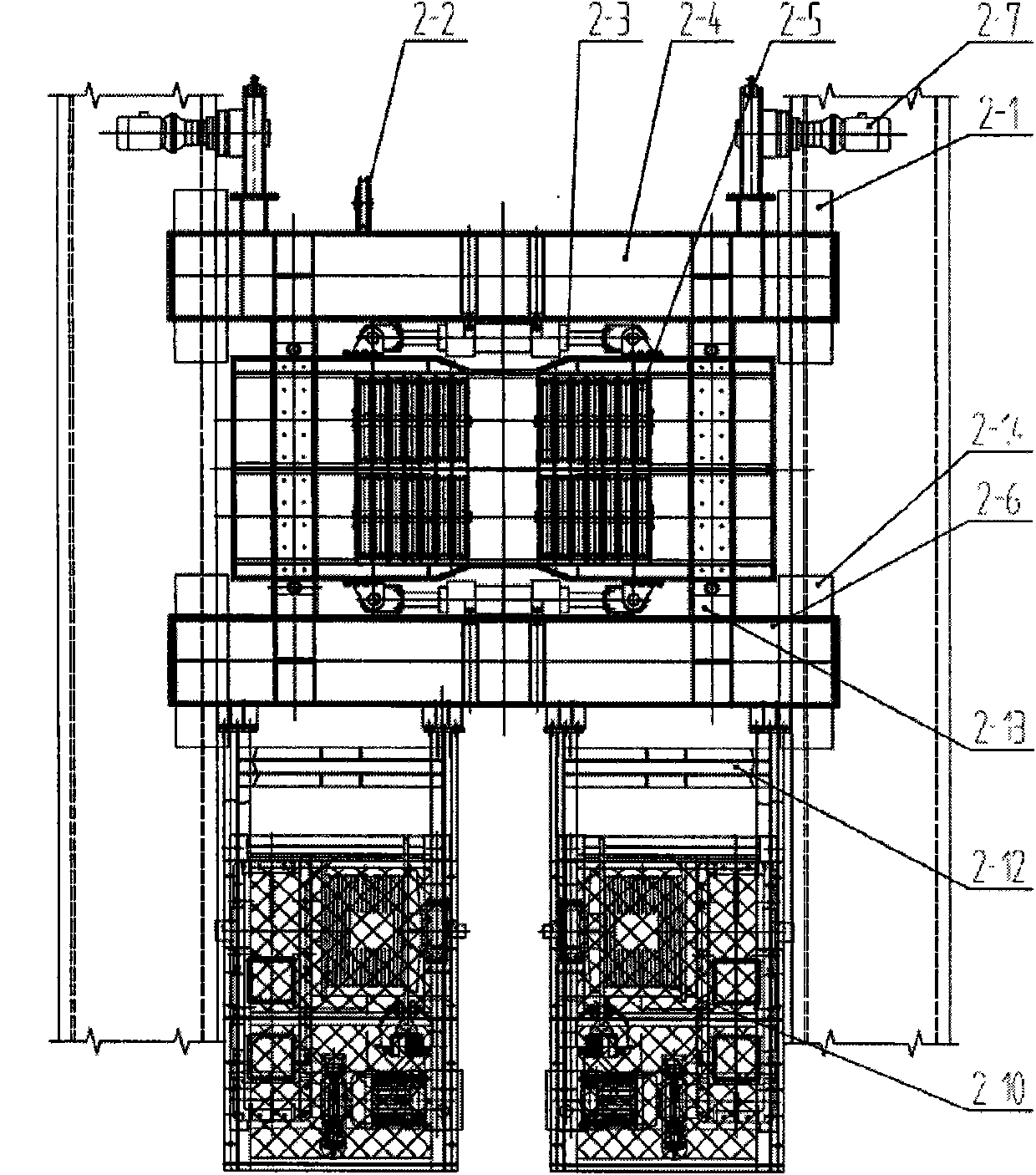

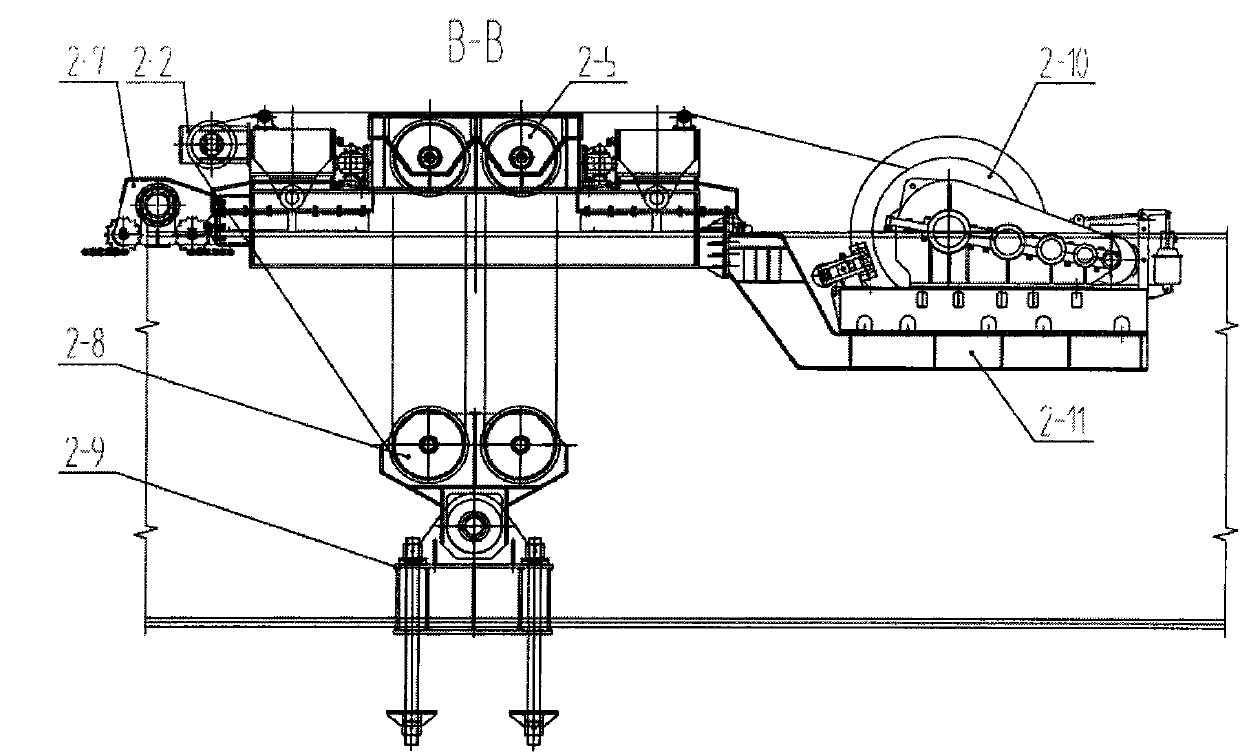

[0056] Such as figure 1 , figure 2 As shown, the present invention is composed of a rear outrigger 1, two flat beam cranes 2, a double main beam 3, a front outrigger 4, an auxiliary outrigger 5, and a concave tire-type beam carrier 6 (number in the figure) 7 means concrete beam to be erected).

[0057] by Figure 15 It can be seen that the foot of the two columns of the rear leg 1 is equipped with walking trolleys 1-4 to ride on the upper cover rails of the main beams 6-6 on both sides of the concave tire type beam transport vehicle 6. At the same time, the upper ends of the two uprights are connected to the corbels 3-2 on the rear side of the main beam through the front and rear pairs of horizontal pins 1-2. When the front horizontal pins 1-2 are pulled out, the rear outrigger 1 It can be folded back from the cylinder 1-3 (around the horizontal pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com