Insertion prepared hole venting reinforcing steel bar lap joint structure fabricated construction method

A construction method and technology of reserved holes, applied in structural elements, building components, building structures, etc., can solve the problems of complex construction and inapplicability of prefabricated concrete structures, and achieve saving of construction funds, easy construction quality assurance, and reliable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

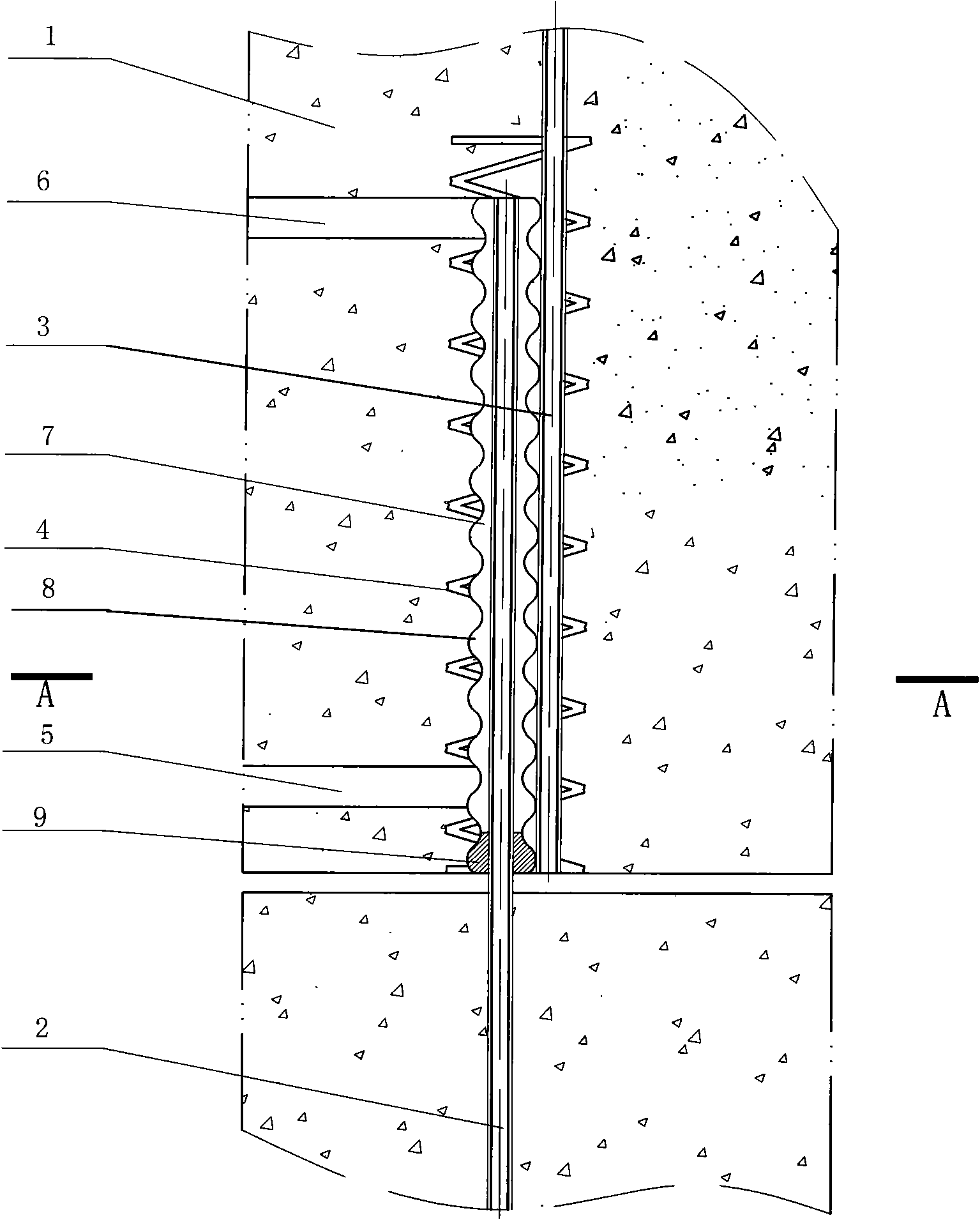

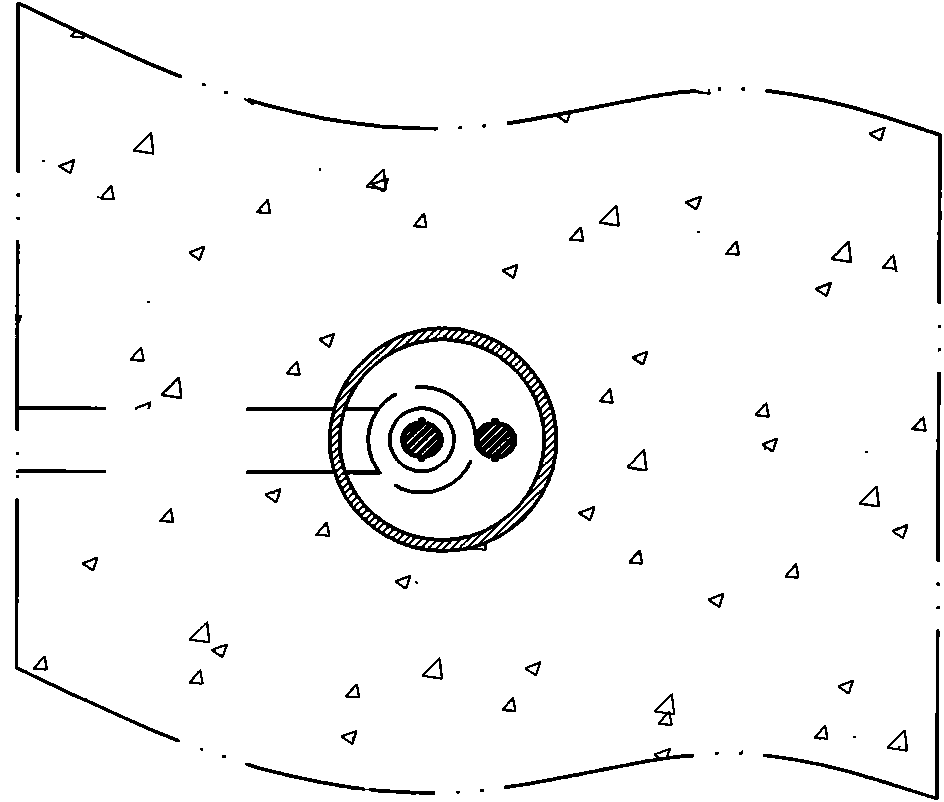

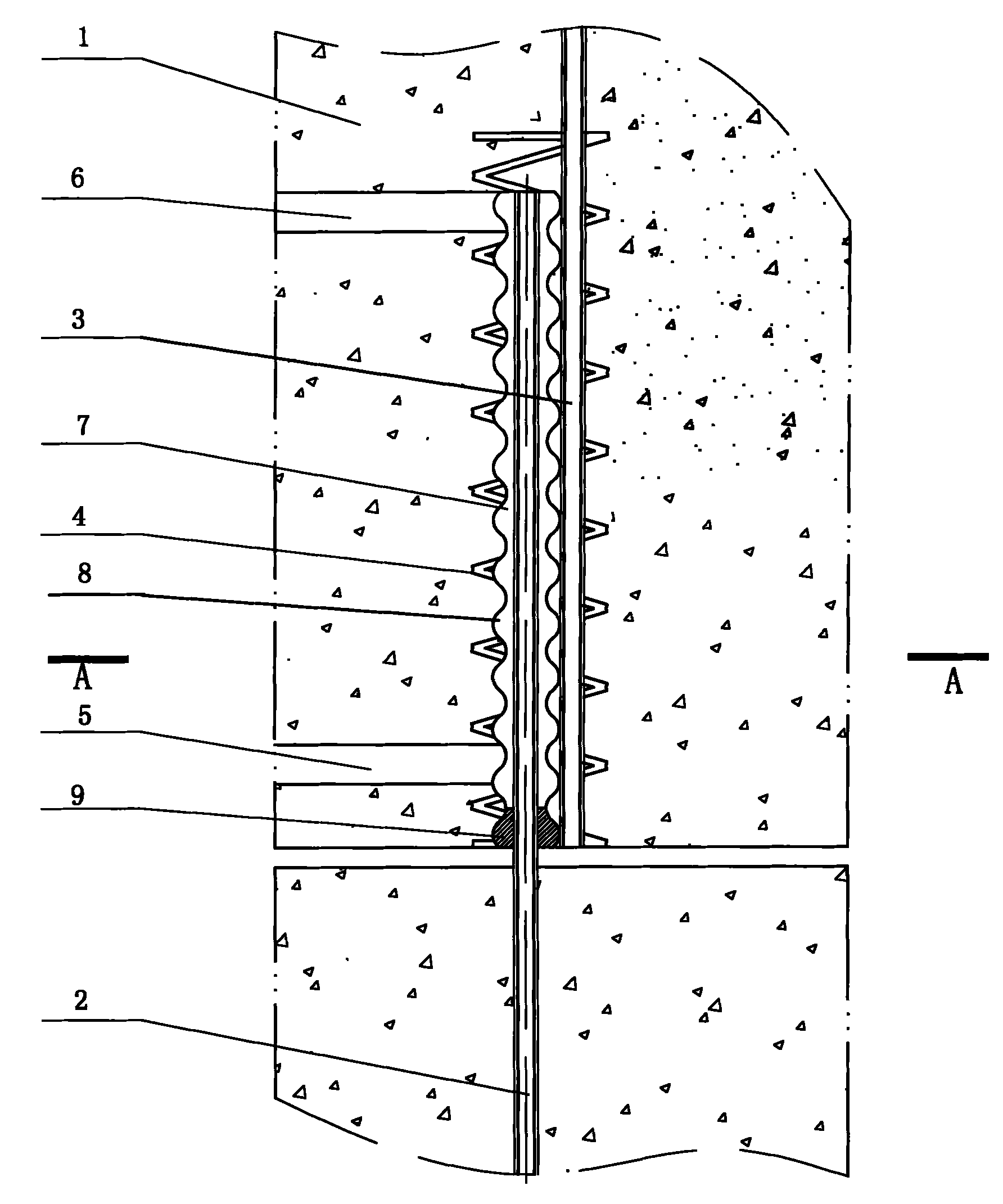

[0017] The plug-in prefabricated hole exhaust steel bar lap joint structure assembly method comprises: a prefabricated concrete component 1, the prefabricated concrete component 1 has a pre-embedded steel bar 2, and the pre-embedded steel bar 2 has a connecting steel bar next to it 3. There are holes reserved beside the pre-embedded steel bars, reinforcing ribs 4 are arranged along the length direction around the pre-embedded steel bars and holes, and the grouting holes 5 and vent holes 6 are connected inside the holes.

[0018] In the assembly construction method of the plug-in reserved hole venting steel bar lap structure, the grouting hole is connected to the lower part of the hole, and the vent hole is connected to the top of the hole.

Embodiment 2

[0020] In the plug-in reserved hole venting steel bar lap joint structure assembly method described in Example 1, the shape of the inner wall of the hole along the length direction is a non-smooth shape, which can be corrugated 7, threaded, grooved, point shape.

Embodiment 3

[0022] The plug-in reserved hole venting steel bar lap joint structure assembly method described in Example 1, the reinforcing rib is in the shape of a spiral or a closed ring, and the outer diameter of the reinforcing rib is larger than the total diameter of the hole and the pre-embedded reinforcing bar. outside diameter.

[0023] working principle:

[0024] The corrugated hole 8 of the plug-in reserved hole venting steel bar lap structure assembly method is reserved next to the lower end of the pre-embedded steel bar 2 of the precast concrete member, and the corrugated hole 8 is designed with a grouting hole 5 connected to it. The air vent 6 is pre-embedded around the corrugated hole 8 and the pre-embedded steel bar 2 at the same time, with reinforcing ribs 4 arranged along the length direction of the hole. When the prefabricated concrete member is hoisted and installed, the connected steel bar 3 is inserted into the corrugated hole 8 to the design overlap length, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com