Method for manufacturing and mounting 120-meter long roof tile at high altitude

An installation method and roof tile technology, applied in the field of roof tiles, can solve the problems of high labor cost of large-scale construction machinery, difficulty in high-air transportation, and easy deformation of finished products, so as to reduce mechanical costs and labor costs, shorten construction period, and reduce materials. The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

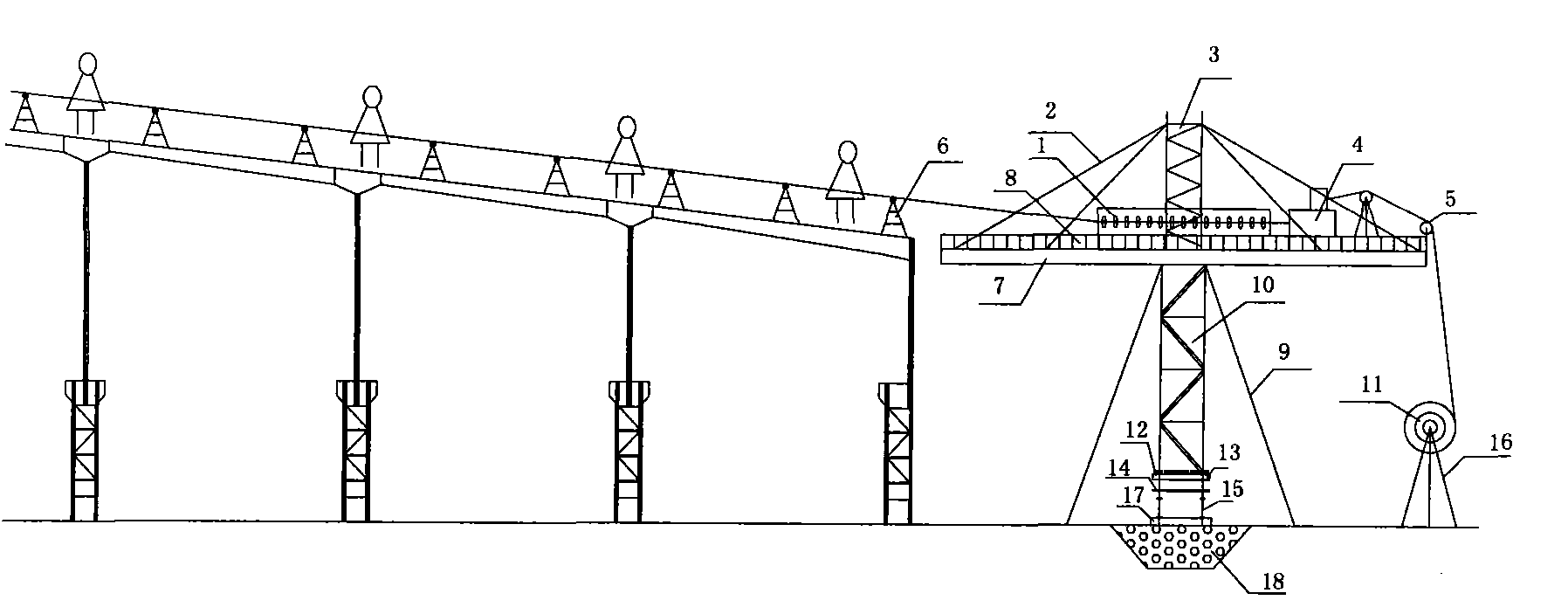

[0040] see now figure 1 , figure 1 It is a schematic diagram of the construction of high-altitude tiles. As shown in the figure, the installation of the high-altitude mobile platform 7 includes:

[0041] (a) track 15 and roadbed 18 with a length of 36m are installed;

[0042] (b) Install QU80 tower base 13 (gauge 6 meters);

[0043] (c) Install QU80 tower counterweight;

[0044] (d) Install H300, 2.3mX20m combined installation press platform;

[0045] (e) Install YX114-333-666 special tile pressing machine 4 for tiles;

[0046] (B) Installation of roof tiles, including:

[0047] (a) provide a substrate, the substrate is a steel coil, preferably a YX114-333-666 type plate;

[0048] (b) Pressing and conveying roof tiles;

[0049] (c) Fix with self-tapping and self-drilling nails.

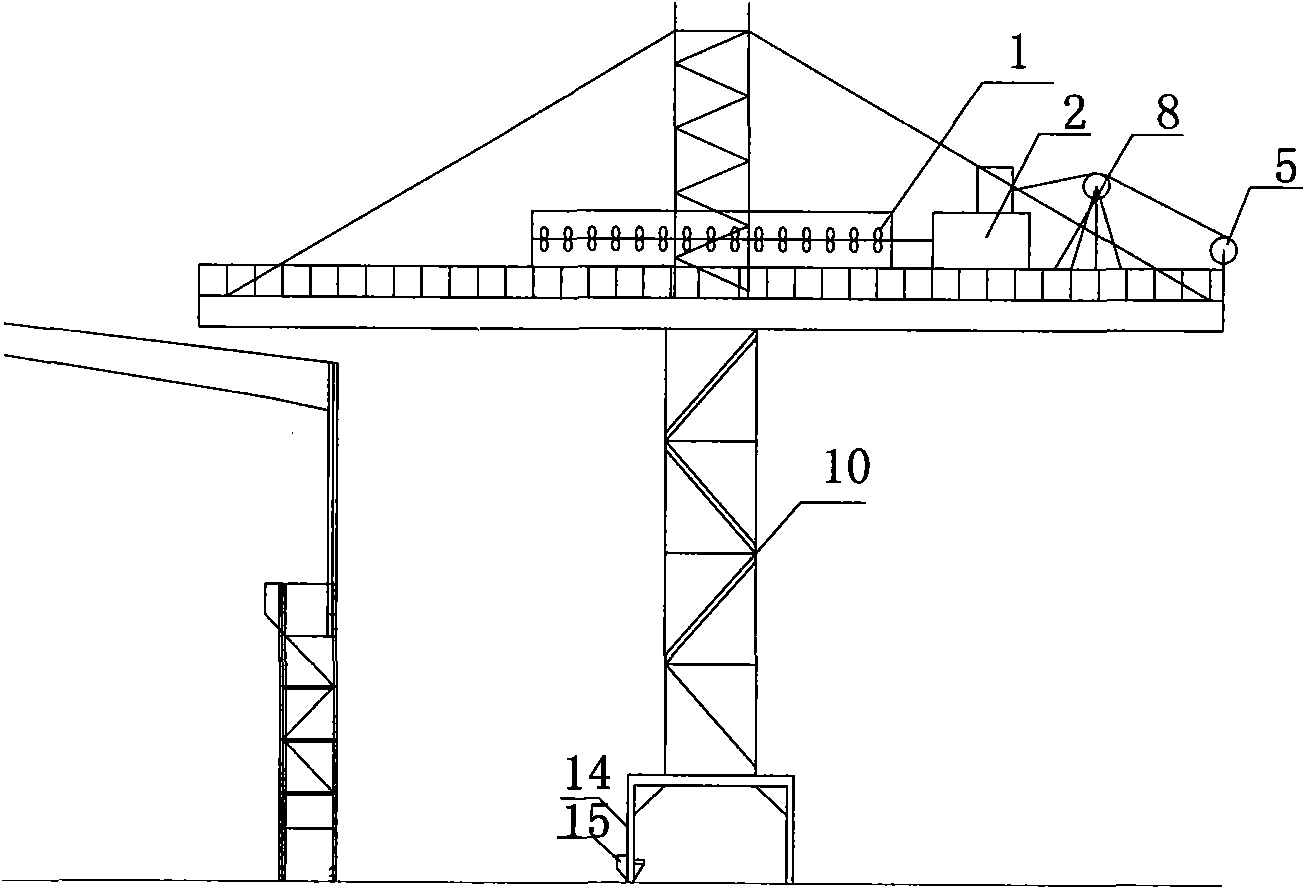

[0050] figure 2 It is shown that the tile press 4 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com