Batch production method for color steel brick

A mass production, color steel brick technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of scattered production process links, poor product quality consistency, not suitable for mass production, etc. The process is compact, the consistency of product quality is good, and the amount of labor is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

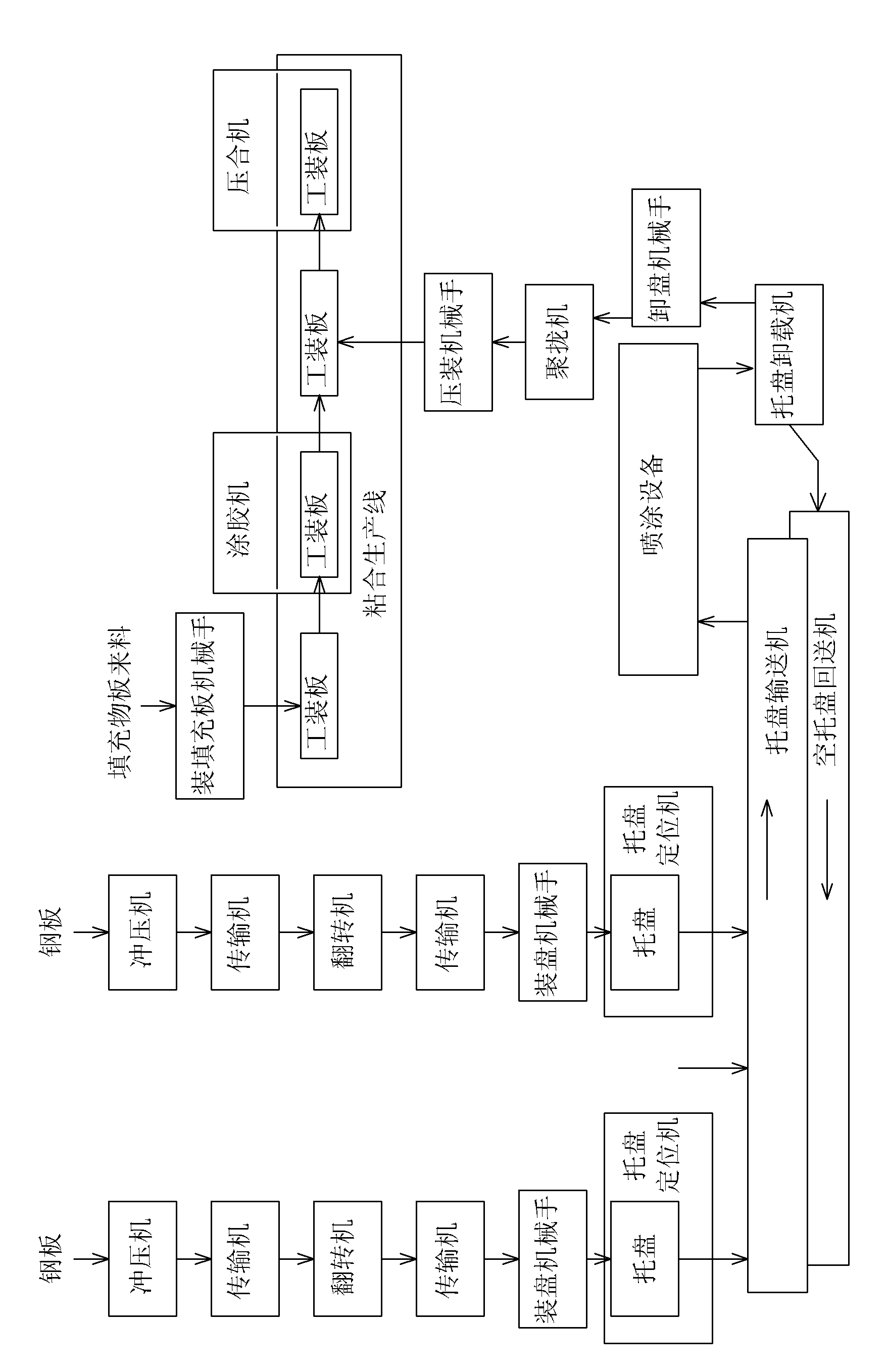

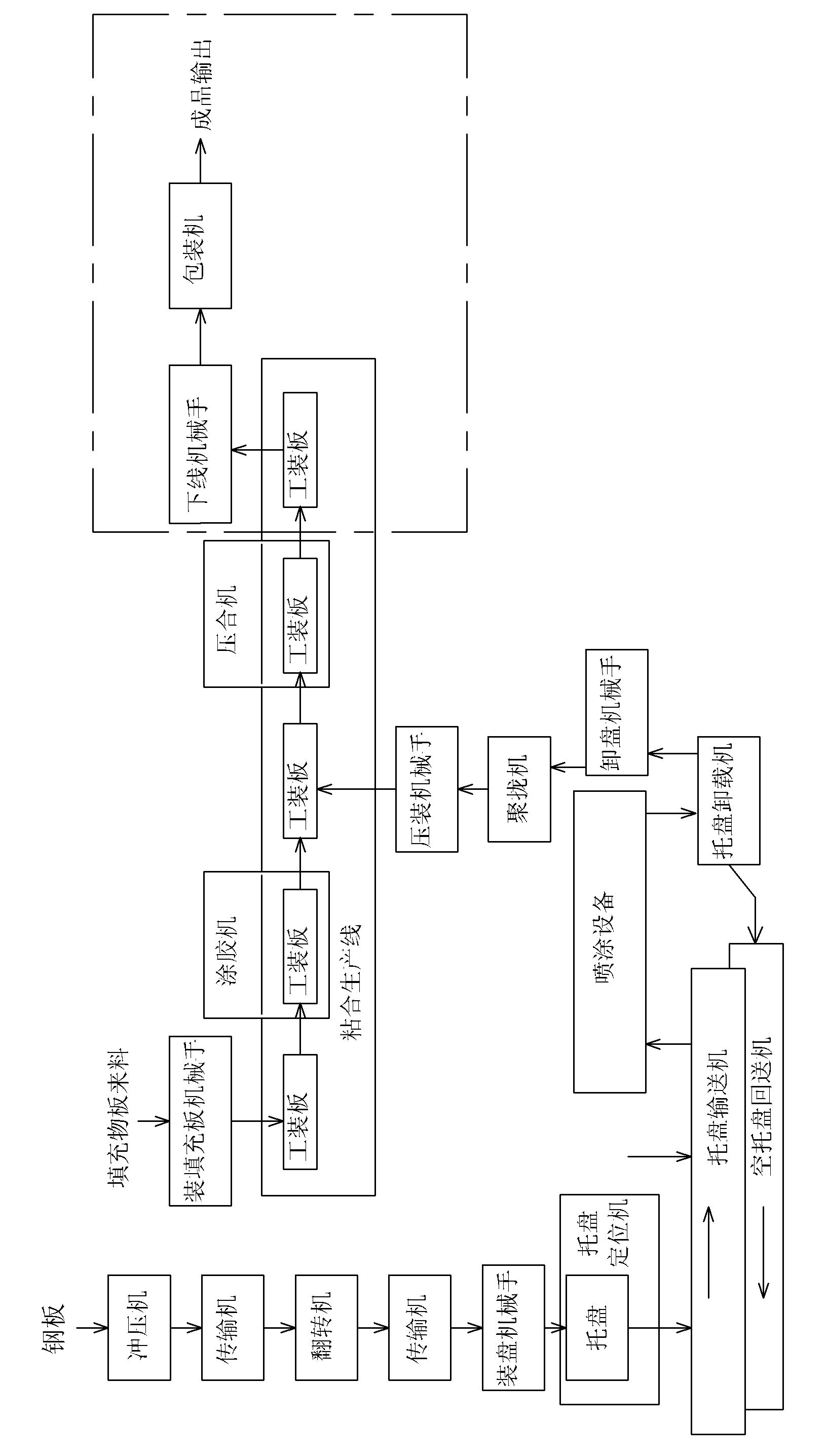

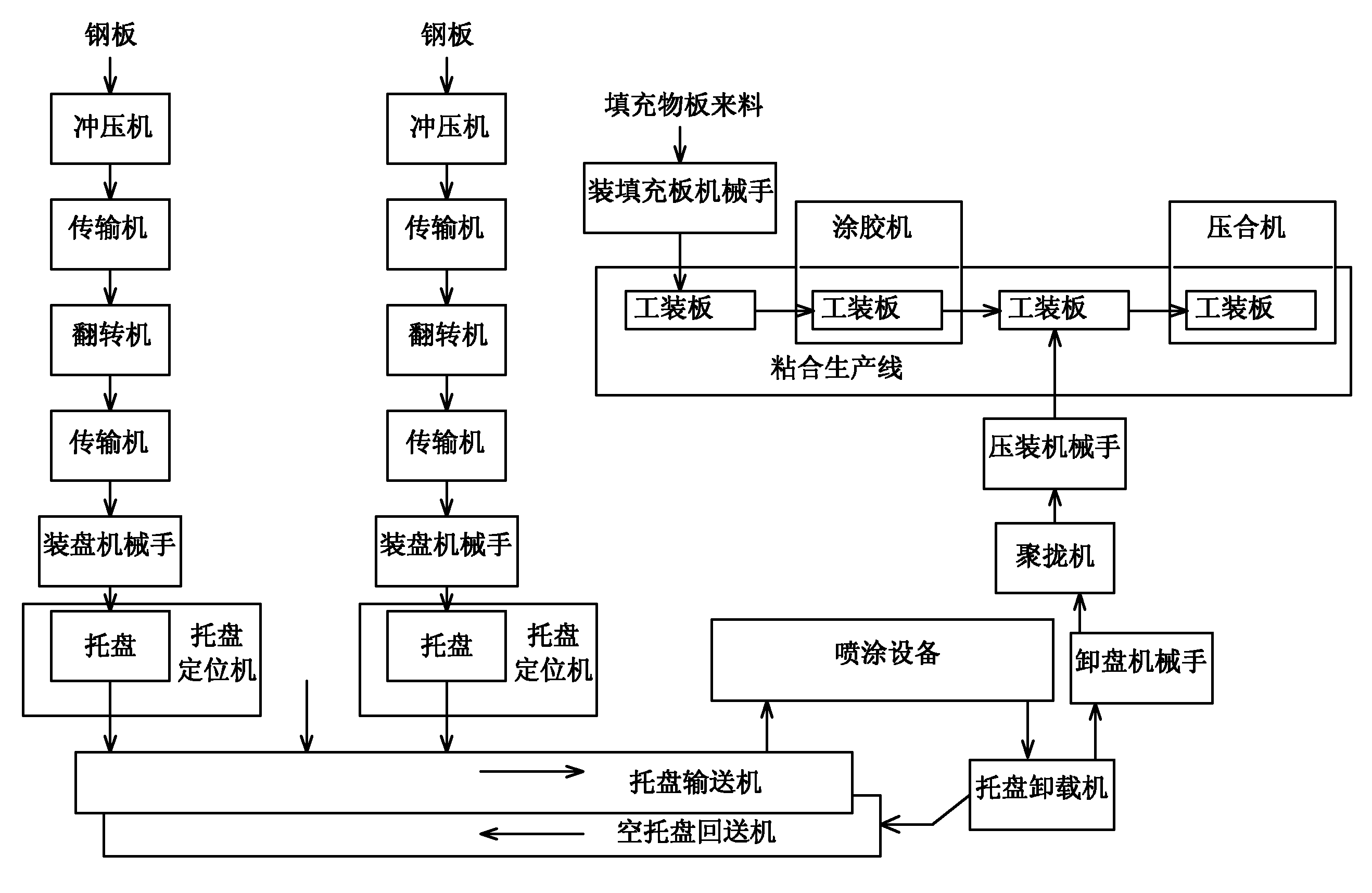

[0013] Specific implementation mode one: combine figure 1 and figure 2 Describe the present embodiment, the process of the batch production method of the color steel brick of the present embodiment is as follows:

[0014] Step 1: The steel plate is automatically loaded in the punching machine and stamped at a frequency of 1Hz-2Hz to form a steel shell, and each steel shell is sequentially dropped on the first conveyor with the opening direction upward, and each steel shell is sequentially It is transferred to the turning machine by the first conveyor, and the turning machine turns each steel shell 180° so that its opening direction is downward, and each steel shell with the opening direction facing downward is continuously conveyed by the second conveyor, and arranged in sequence One row, at this time there is no gap between the steel shell and the steel shell;

[0015] Step 2: The first manipulator, special manipulator or multi-degree-of-freedom robot simultaneously absorb...

specific Embodiment approach 2

[0027] Specific implementation mode two: combination figure 1 This embodiment is described. In Step 3 of this embodiment, the pallet carrying the steel shell is placed on the spraying equipment through mechanical equipment. The advantages of adopting this method are: saving manpower and high production efficiency. Other method steps are the same as those in the first embodiment.

specific Embodiment approach 3

[0028] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the third conveyor in step 3 of this embodiment is made to pass through the spraying equipment, and the steps of hanging and removing the pallet carrying the steel shell are cancelled. For higher volume production requirements. Other method steps are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com