Cyclone air-inlet centrifugal synchronous backward flow fan

A technology of air flow fan and air inlet, which is applied in the field of swirling air inlet and centrifugal synchronous backflow fan, which can solve the problems of unfavorable environmental protection, large eddy current loss, and large air inlet resistance, so as to improve the air inlet effect and increase the flow rate of the fan , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

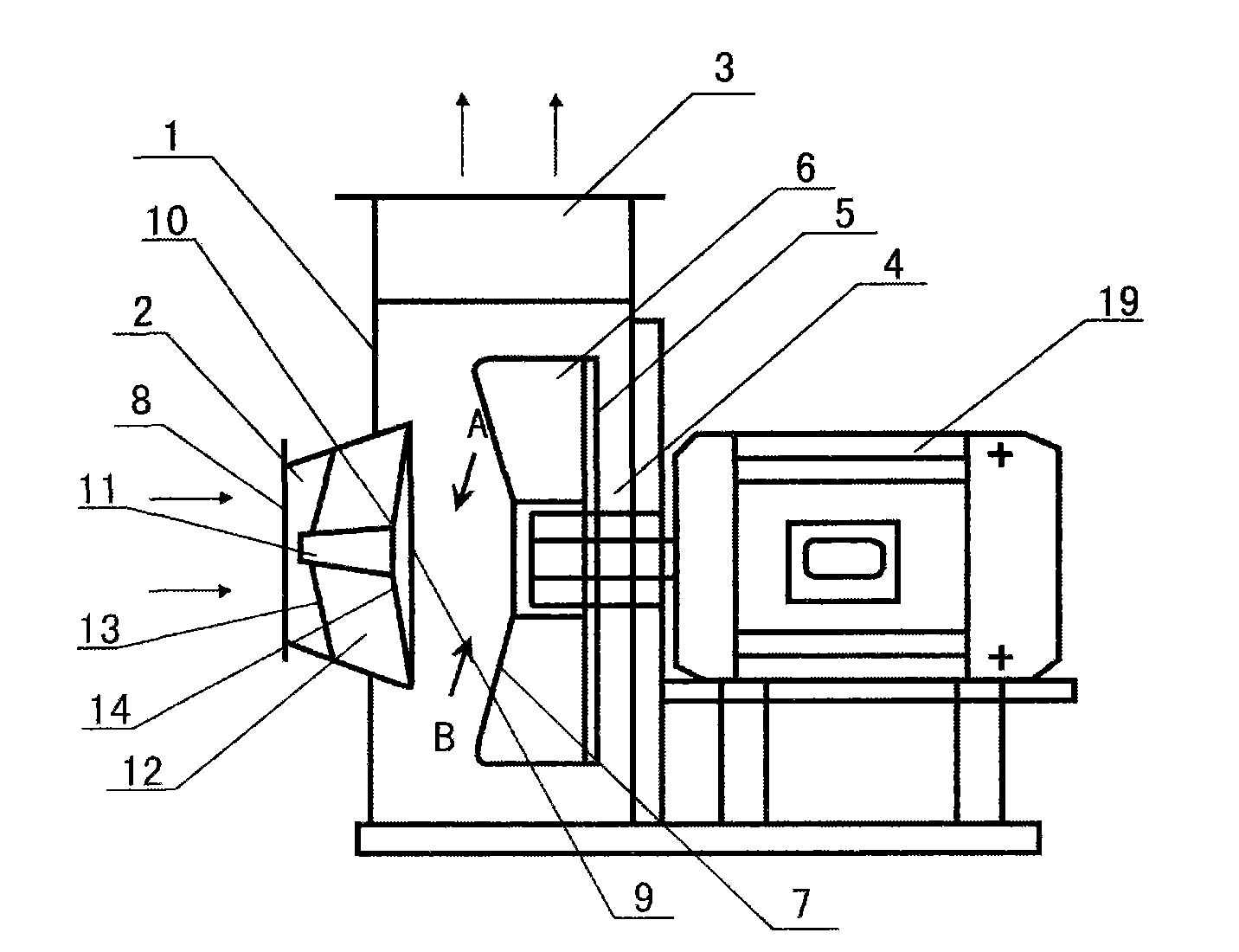

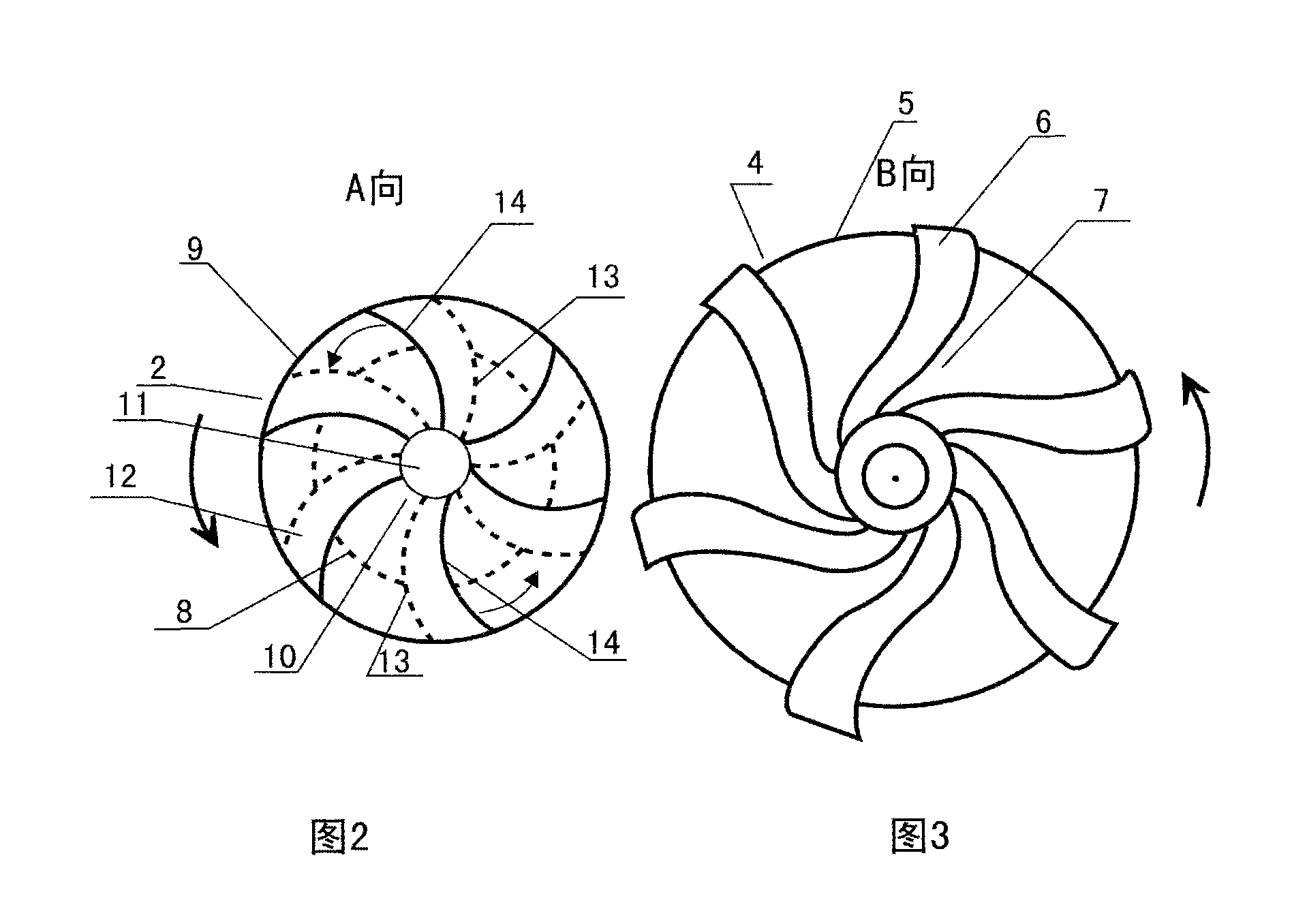

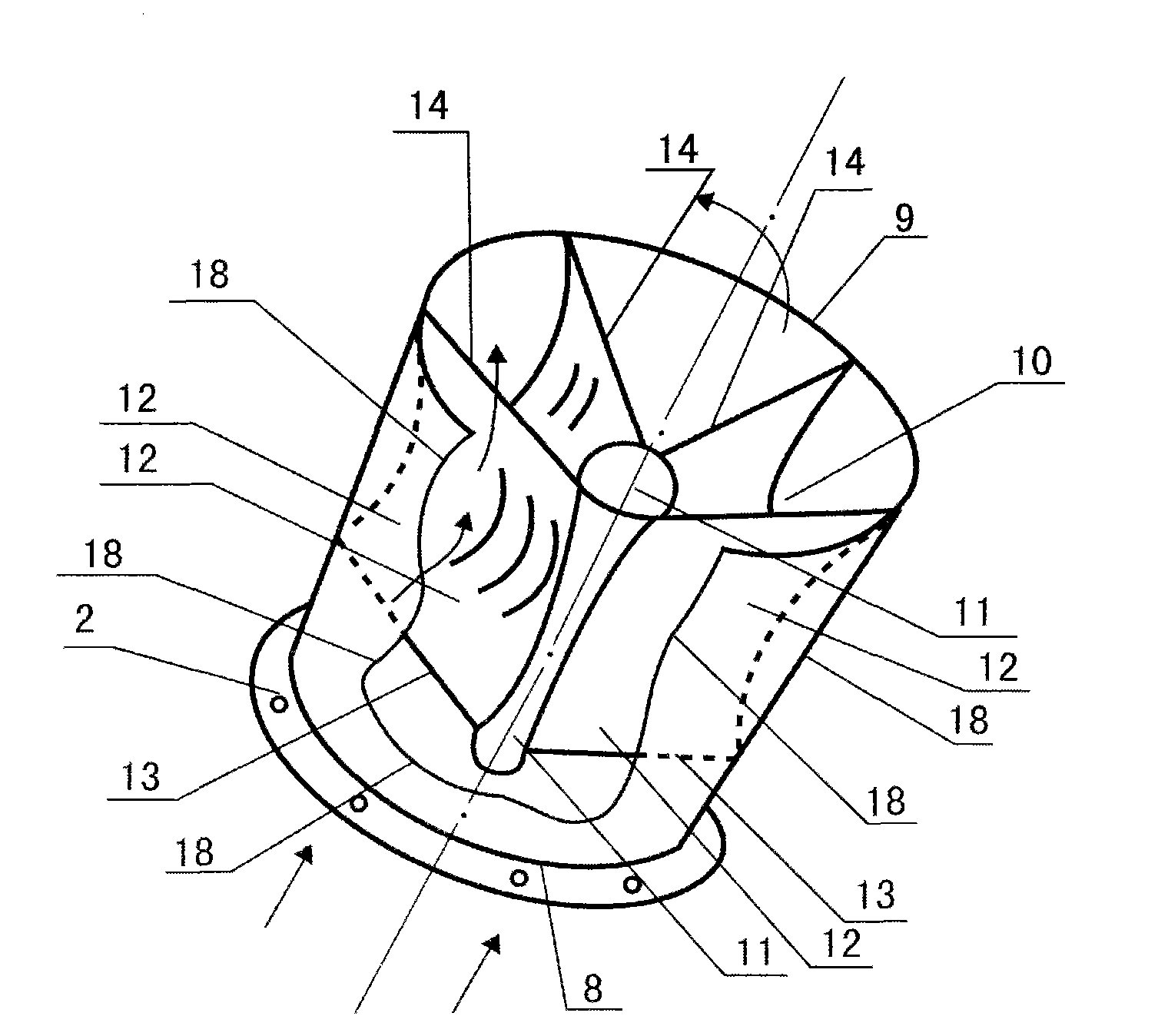

[0035] Embodiment 1, reference figure 1 , figure 2 , image 3 , Figure 4 , a centrifugal synchronous backflow fan with swirl air inlet, comprising a casing 1, an expanded casing air inlet 2, a casing air outlet 3, a backflow fan impeller 4, and a rear side impeller blade disc 5 (no front impeller blisk, no air inlet in the middle of the impeller), three-wall structure impeller blade 6, impeller blade axial inlet 7 (negative pressure gap), impeller air inlet inlet 8, casing air inlet outlet 9, casing air inlet 2 inside There is a swirl inducer 10. The swirl inducer 10 is composed of a conical cylindrical baffle connector 11 and a curved baffle blade 12. The baffle connector 11 runs longitudinally in the middle of the swirl inducer from front to back , the baffle blade 12 is a curved structure, the radial front end of the baffle blade 12 is connected with the baffle connector 11, the radial rear end of the baffle blade 12 is connected with the side wall of the air inlet 2 o...

Embodiment 2

[0041] Embodiment 2, refer to Figure 5 , Figure 6 , Figure 7 , This example is basically the same as Example 1, except that the impeller of this example is provided with an air inlet 15 in the middle of the impeller and a radial inlet 16 of the impeller blades, and the baffle connector is a cone-shaped structure.

[0042] When this example is working, the rotating airflow at the outlet of the air inlet of the casing will enter the inner flow channel of the impeller tangentially from two parts of the radial inlet 16 of the impeller blade and the axial inlet 7 of the impeller blade of the air inlet in the middle of the impeller, so that the impeller can be sucked in more. More air volume for processing.

[0043] This example is suitable for making various large-flow ventilators to use.

Embodiment 3

[0044] Embodiment 3, refer to Figure 8 , this example is basically the same as Example 2, the difference is that the impeller 4 of this example is a synchronous backflow ventilation compressor impeller, the whole impeller is a conical cylinder structure, the impeller blades are a synchronous backflow fan impeller blade structure, and the impeller blades are provided with There are synchronous diversion supercharger 17 and synchronous downstream inlet 7. The axial front side of the impeller is also provided with the air inlet 15 in the middle of the impeller, the radial (inclined) inlet 16 of the impeller blade is provided, and the axial inlet 7 of the impeller blade (synchronous downstream inlet) is provided. The baffle connector of the swirl flow inducer is in the form of a conical cylinder that expands from front to back.

[0045] When this example is working, the rotation direction of the airflow at the air inlet outlet 9 of the casing is opposite to that of the impeller,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com