Hydraulic coupler

A technology of hydraulic couplings and jackets, applied in couplings, rigid shaft couplings, mechanical equipment, etc., can solve problems such as pulling or even seizure, low friction coefficient and power transmission capacity, and scrapped couplings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

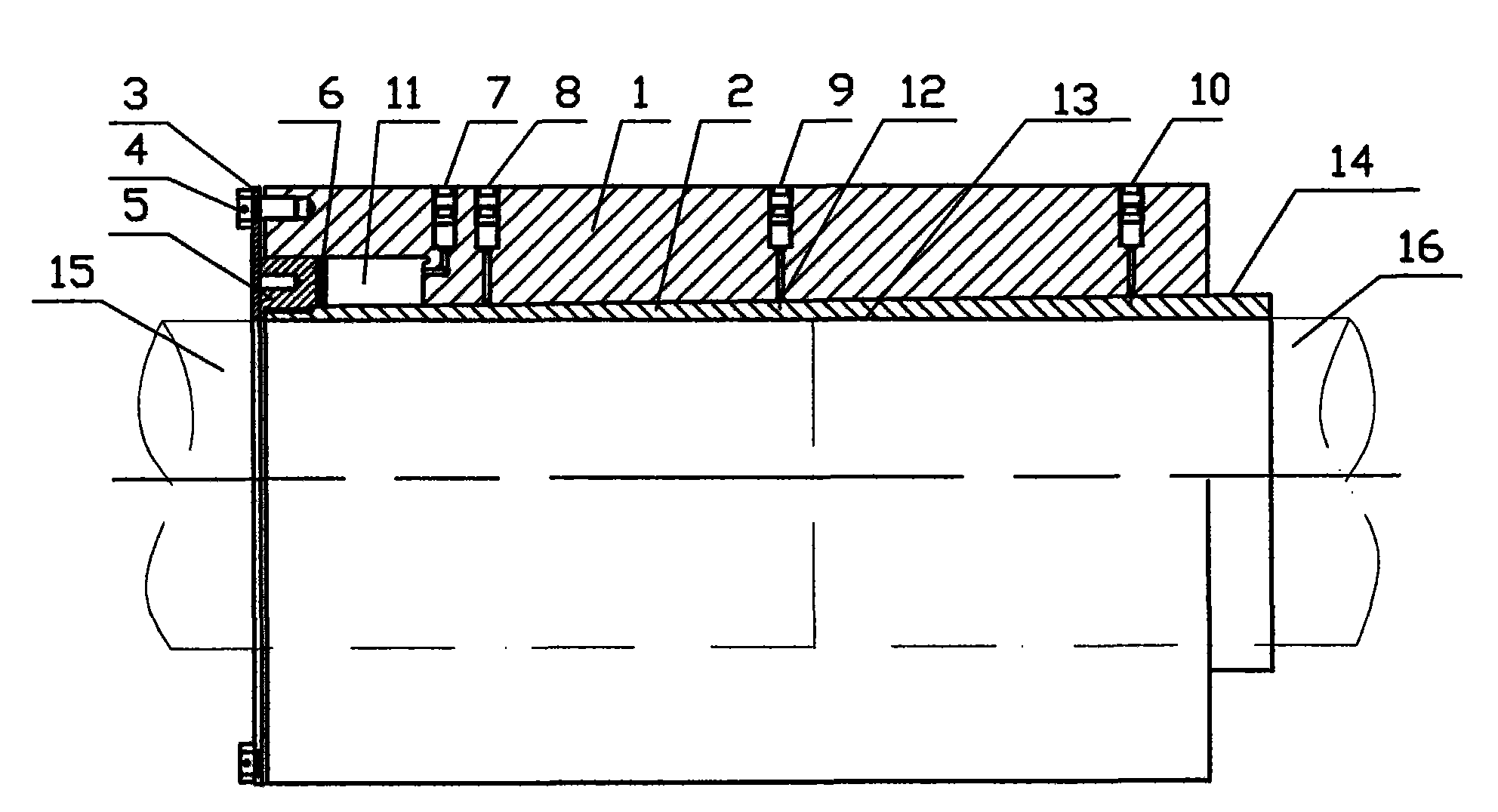

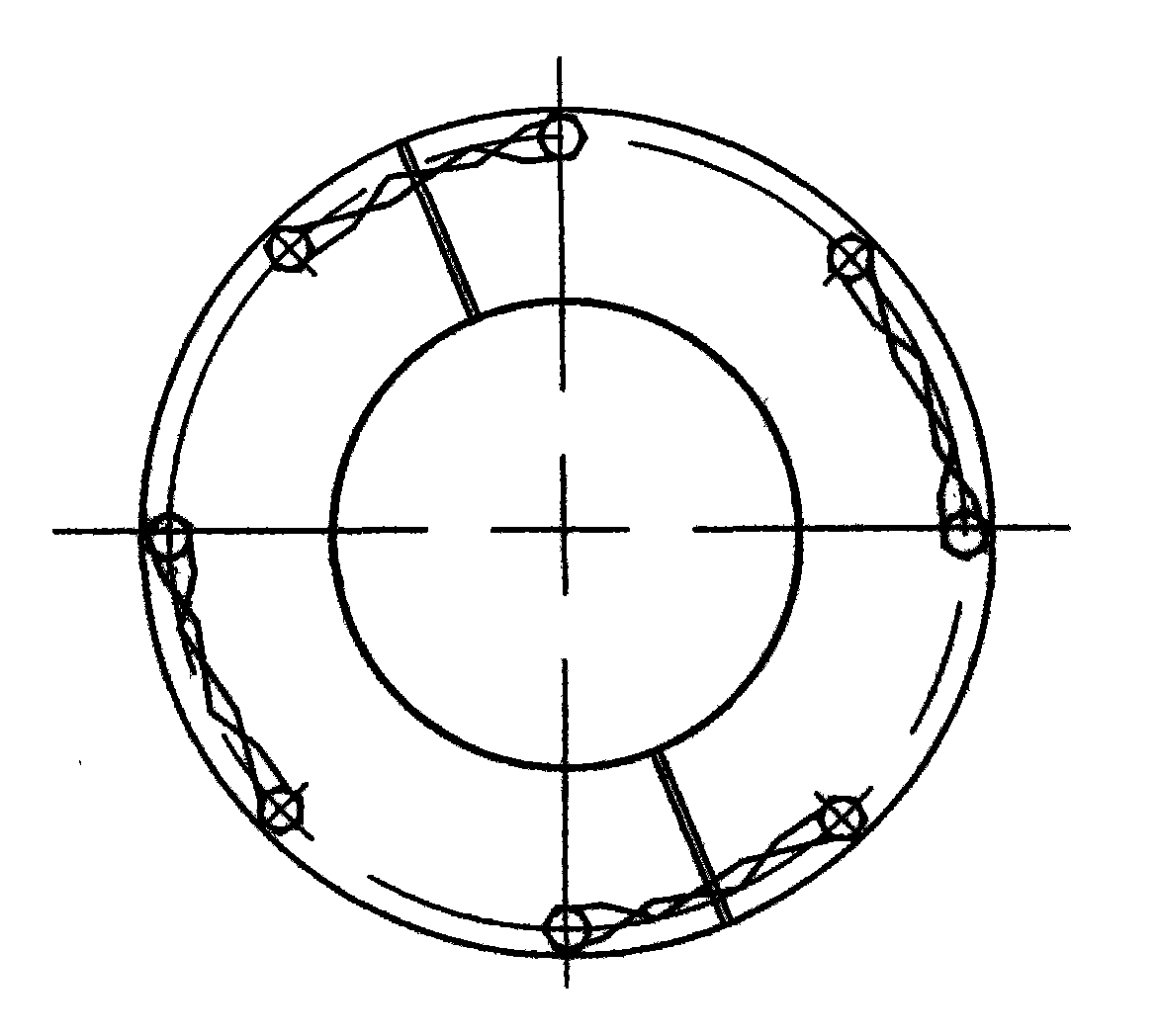

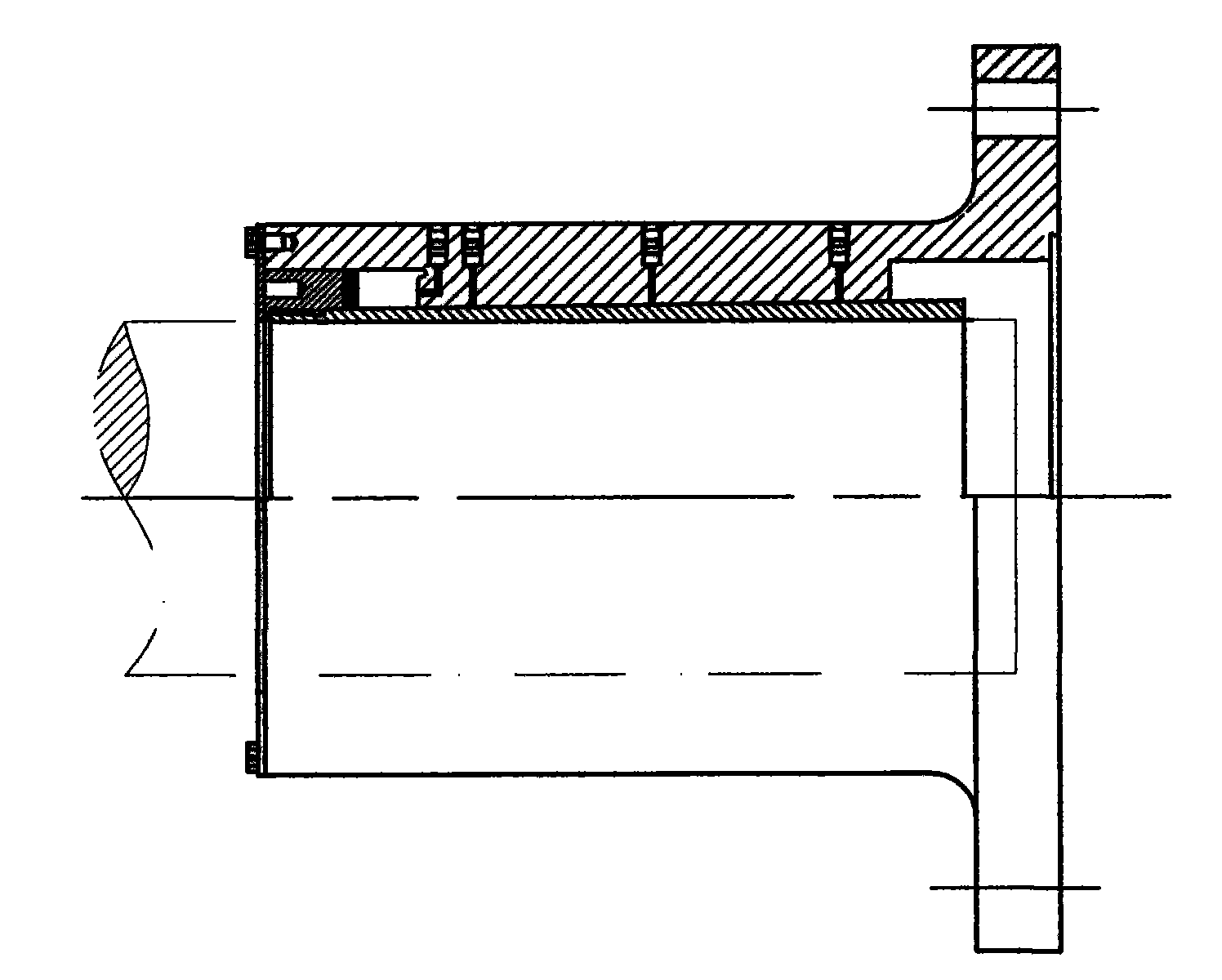

[0021] Such as figure 1 , figure 2 Shown, sleeve-type hydraulic couplings, including:

[0022] Jacket: the inner surface 12 is conical, the outer surface is cylindrical, and has a spiral oil groove; one end is processed into a step shape, which is used as the piston area 11 to push the outer jacket to move axially; there are several oil injection holes on the outer jacket, one of which is It is used to inject oil into the piston area 11 to generate axial displacement, and the rest communicates with the oil groove on the inner surface 12 of the casing for radial expansion.

[0023] Inner sleeve: its inner surface 13 is cylindrical, and there are several helical grooves for oil storage, and the outer surface 14 is conical; one end of the inner sleeve is processed into threads for connecting with the piston.

[0024] Piston 5: its inner hole is threaded and connected with the inner sleeve, and a sealing ring 6 is provided.

[0025] The outer sleeve, the inner sleeve and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com