Vacuum toilet dejecta collector gate valve

A gate valve and vacuum collection technology, which is applied in the field of the collection system of passenger transportation vehicles, can solve the problems of high failure rate, high air leakage and failure rate, and poor sealing performance of imported butterfly valves and slide valves, so as to reduce the application of The effect of cost, reasonable structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

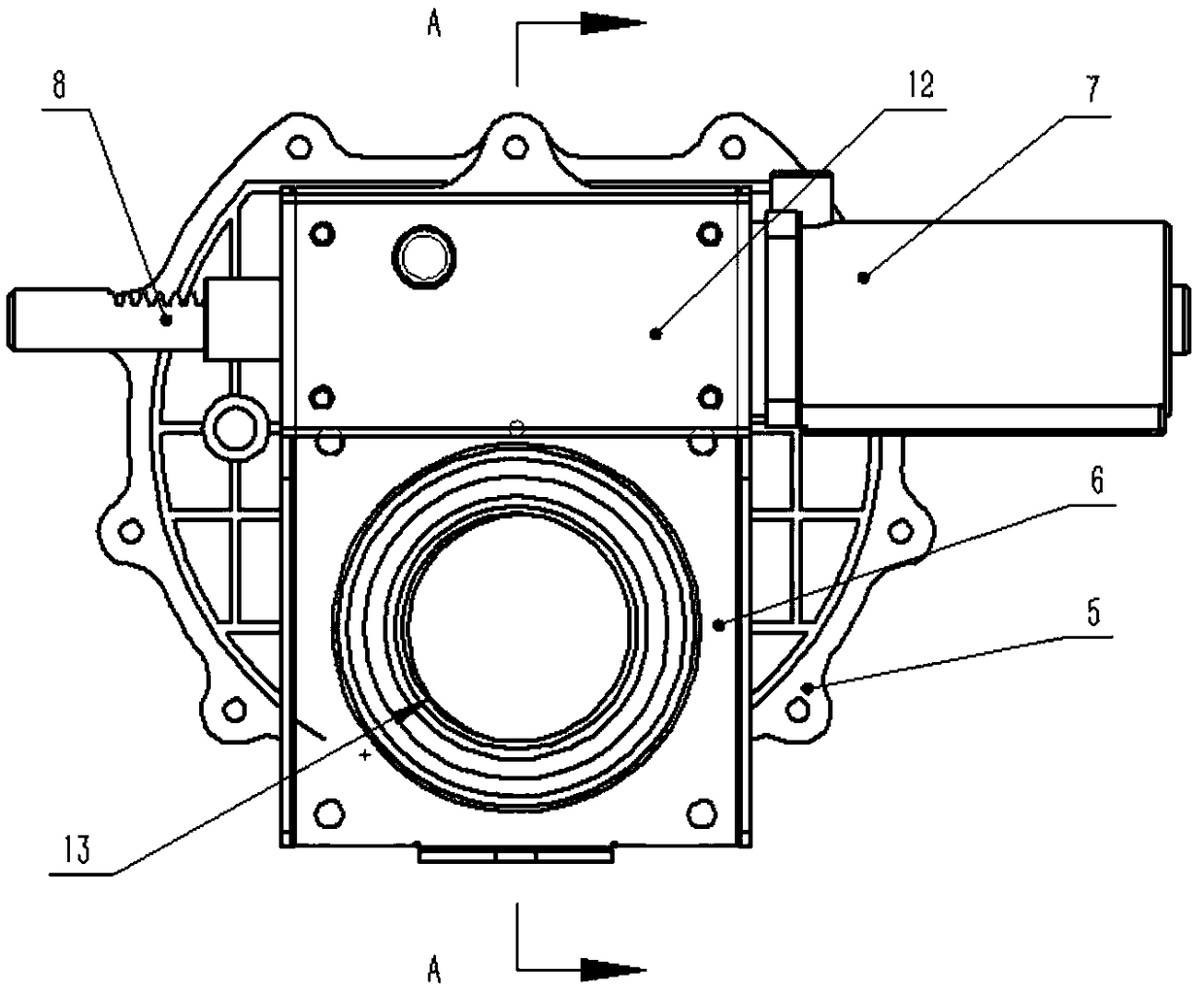

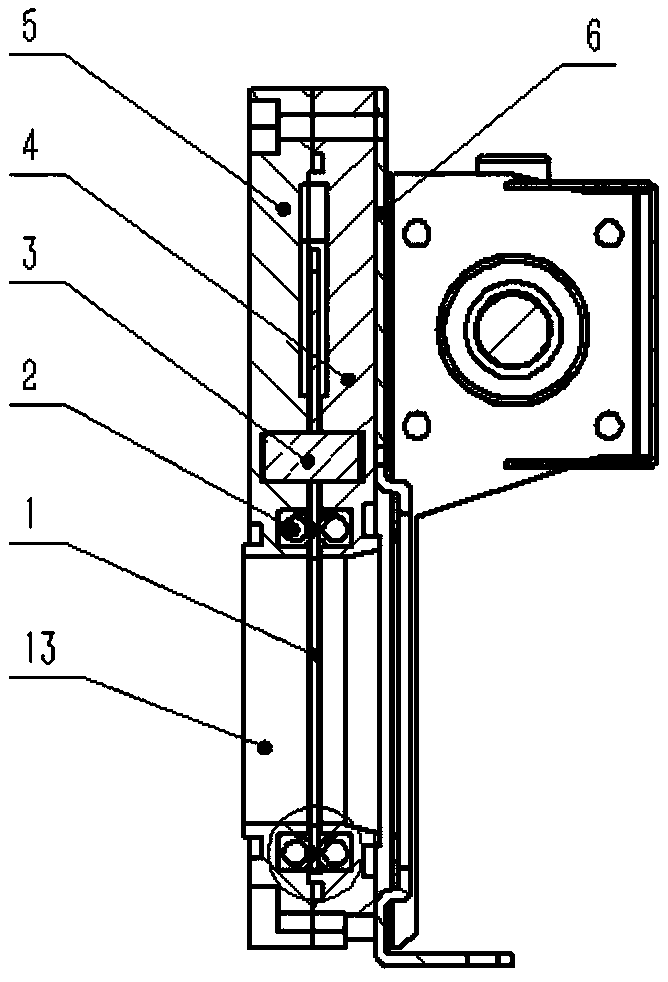

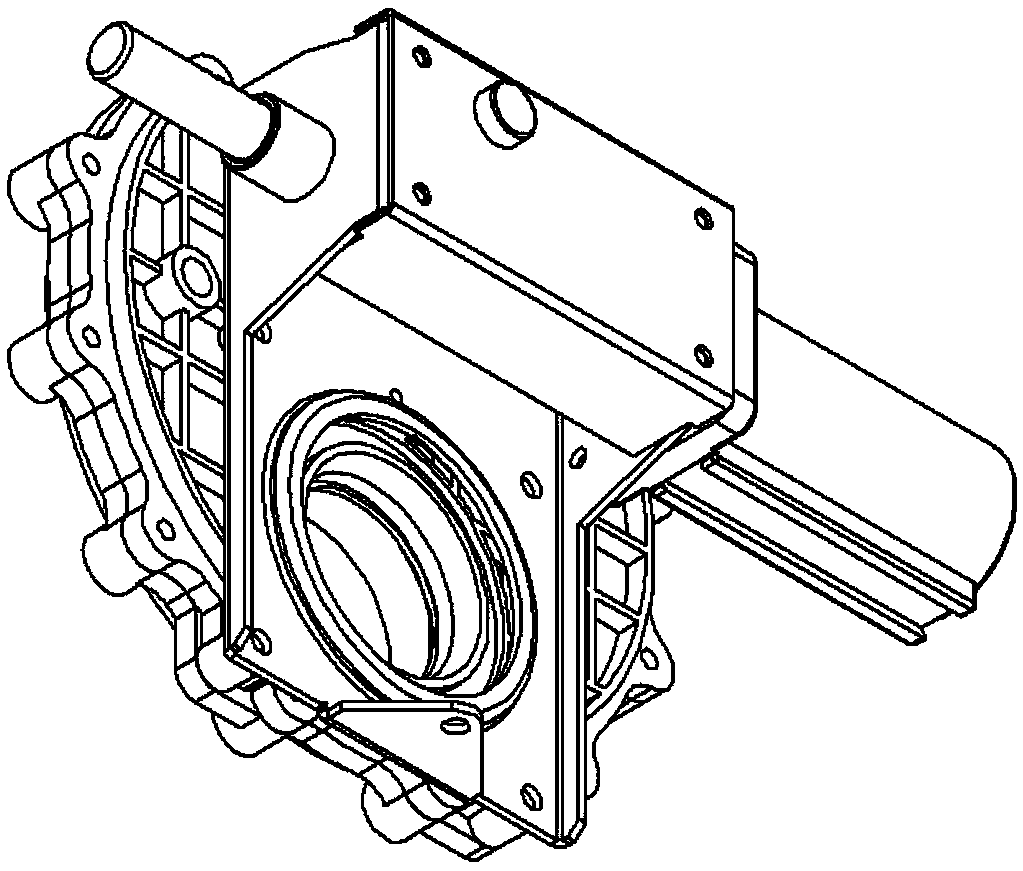

[0026] The structure of each part of the gate valve of the vacuum type lavatory pan of the present invention is as follows: Figure 1-7 shown.

[0027] In order to be applicable to the structure of the existing vacuum feces collection system, the upper splint 4 and the lower splint 5 are designed in a crescent shape.

[0028] The gate plate 1 and the gear of the vacuum toilet gate valve are as follows: Figure 6 As shown, the modulus of the gear is 1, and the number of complete gear teeth is 60. Here, only a part of the gear is required, see 102; 101 is the gear shaft hole, which is also the central shaft hole of the gate 1, which can be pushed under the action of the driving gear. The gate 1 rotates; the gate valve opens when the sewage hole 103 on the gate 1 coincides with the sewage hole of the upper and lower splints. The diameter of the hole 103 is 46mm;

[0029] The hollow sealing ring 2 of the gate valve of the vacuum-type toilet collection is open in the natural sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com