Experimental device for simulating 200-meter deep water blasting under moving water state

An experimental device and state-of-the-art technology, applied in blasting and other directions, can solve problems such as low similarity, complex and difficult underwater blasting research, and achieve a reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

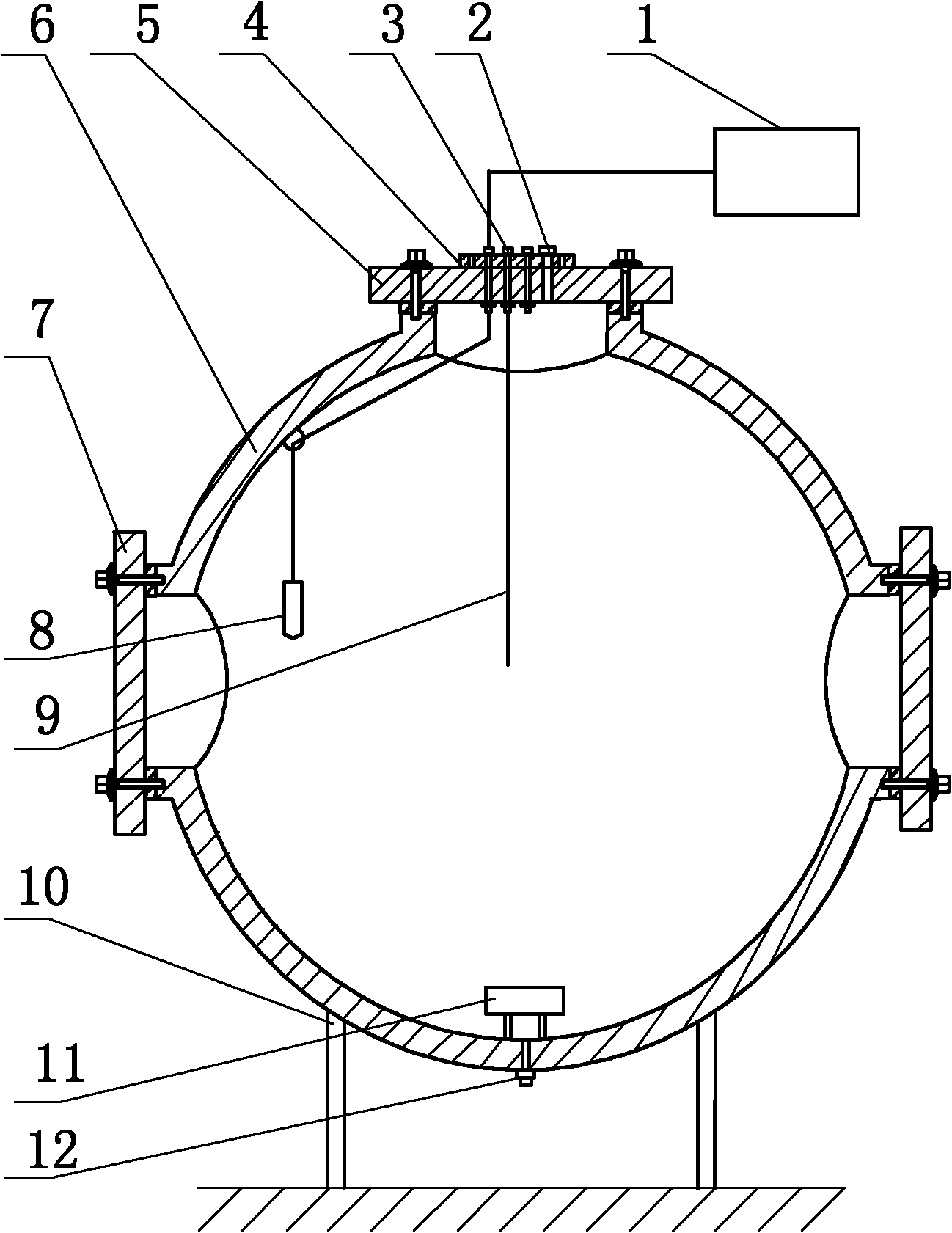

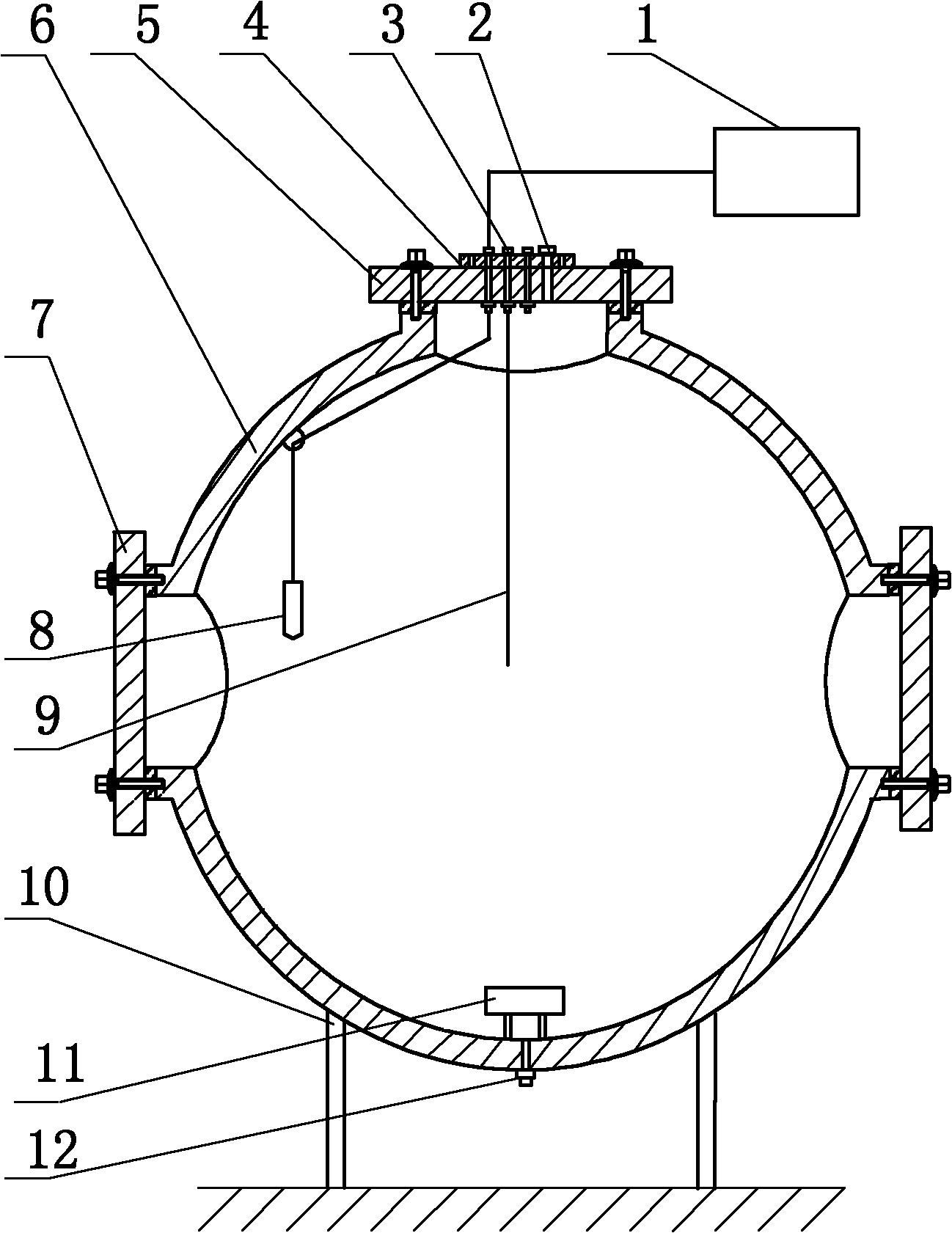

[0017] A 200-meter-level deep-water blasting experimental device under simulated dynamic water state. Such as figure 1 As shown: the device is a hollow spherical tank 6 made of A3 steel, with an inner diameter of 1500-2000 mm and a wall thickness of 5-10 mm; the bottom of the hollow spherical tank is fixed on the base support 10 .

[0018] The tank body of the hollow spherical tank 6 is symmetrically provided with two observation windows 7, and the center line of the two observation windows 7 passes through the center of the tank body 6. The diameters of the observation windows 7 are both 200-300mm, and the observation windows 7 are Equipped with plexiglass.

[0019] The top of the hollow spherical tank 6 has a working hole, and the working hole is equipped with a mounting cover 5. The mounting cover 5 is provided with three penetration holes 3 with a diameter of 5-7mm and a high-pressure air pipe joint 2. Three penetration holes 3 and the high-pressure air pipe joint 2 are ...

Embodiment 2

[0023] A 200-meter-level deep-water blasting experimental device under simulated dynamic water state. Such as figure 1 As shown: the device is a hollow spherical tank 6 made of A3 steel, with an inner diameter of 2000-2500 mm and a wall thickness of 10-15 mm; the bottom of the hollow spherical tank is fixed on the base support 10 .

[0024] The tank body of the hollow spherical tank 6 is symmetrically provided with two observation windows 7, and the center line of the two observation windows 7 passes through the center of the tank body 6. The diameters of the observation windows 7 are all 300-400 mm, and the observation windows 7 are Equipped with plexiglass.

[0025] The top of the hollow spherical tank 6 is provided with a working hole, and the working hole is equipped with an installation cover 5, and the installation cover 5 is provided with three penetration holes 3 with a diameter of 6-8mm and a high-pressure air pipe joint 2, the penetration hole 3 and the high-pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com