Wind power locking disc test stand

A technology of locking discs and test benches, applied in the direction of measuring torque/torsion force, measuring devices, instruments, etc. during tightening, can solve problems such as unsafe hidden dangers, complex structures, poor synchronization, etc., and achieve small test sites and short test time , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

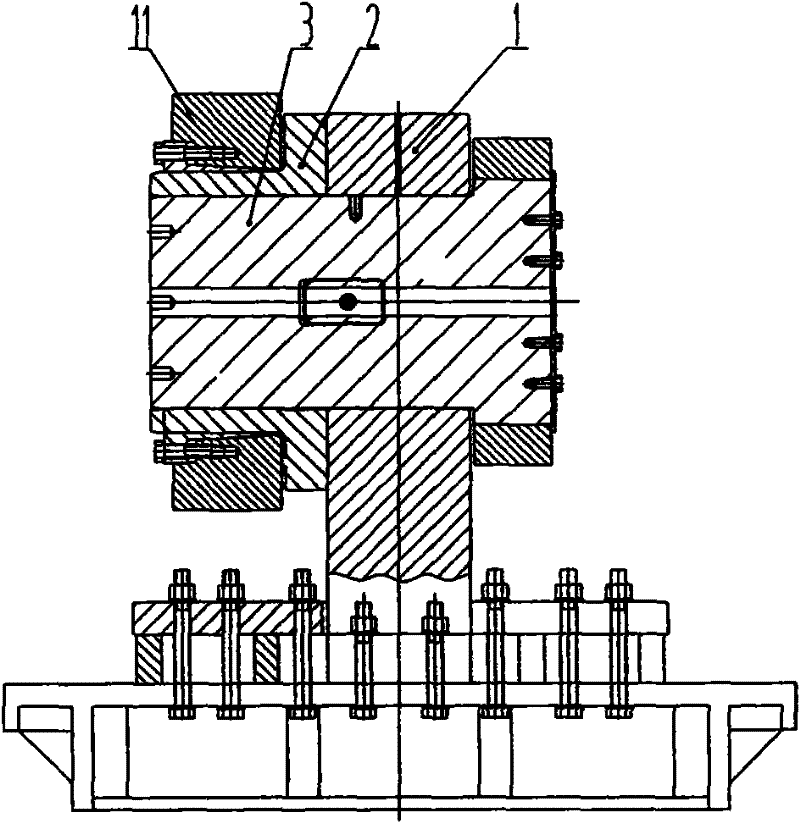

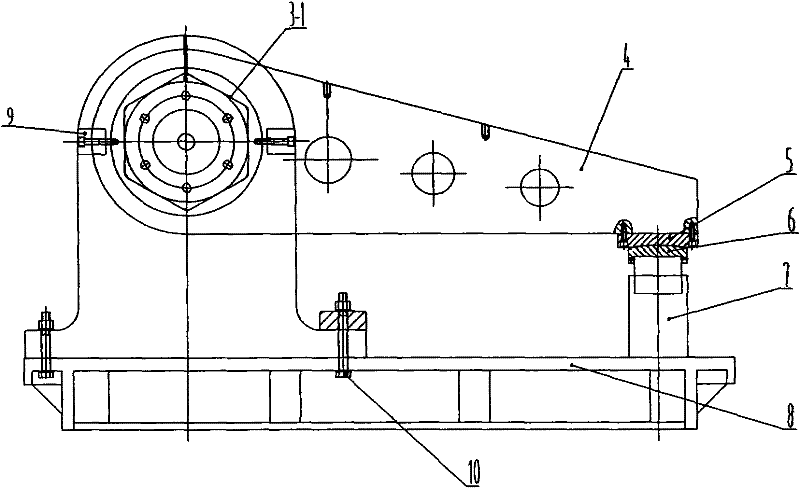

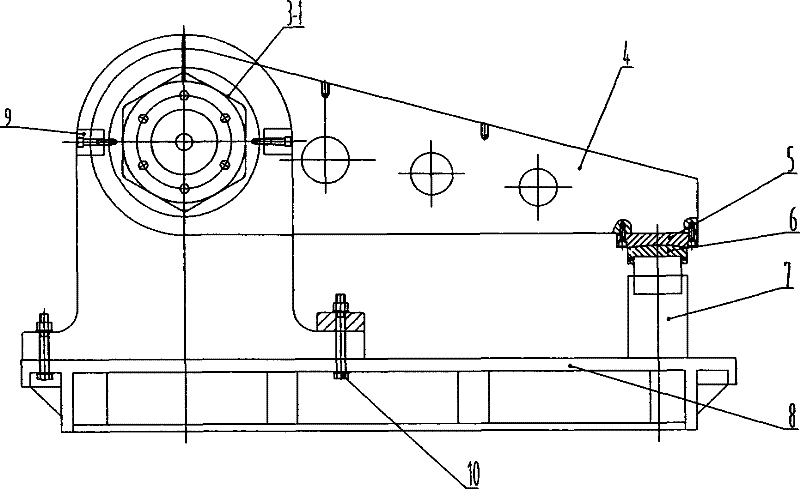

[0009] Such as figure 1 figure 2 As shown, the present invention is a wind power shrink disk test bench. The wind power shrink disc test bench includes a support frame 1, a shaft sleeve 2, a main shaft 3, a force arm 4, a convex spherical backing plate 5, a concave spherical top cover 6, a jack 7, a base 8, a key 9 and a bolt 10. The support frame is fixed on the base, the main shaft is installed in the support frame, one end of the main shaft is equipped with a shaft sleeve, the other end of the main shaft is equipped with a moment arm, the convex spherical backing plate is installed at the place where the single moment arm is stressed, and the jack is fixed on the base , The concave spherical top cover is installed on the jack, and the key is installed in the shaft sleeve and the support frame. The moment arm and the main shaft are hexagonal (3-1) clearance fit. The convex spherical backing plate 5 and the concave spherical top cover 6 are in a spherical fit structure. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com