Coin processing device

A technology for processing devices and coins, which is applied in coin receiving devices, coin counting, coin inspection, etc., can solve the problems of reduced friction of elastic parts, reduced coin processing efficiency, and insufficient reliability of coin transmission, and achieves the goal of improving processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

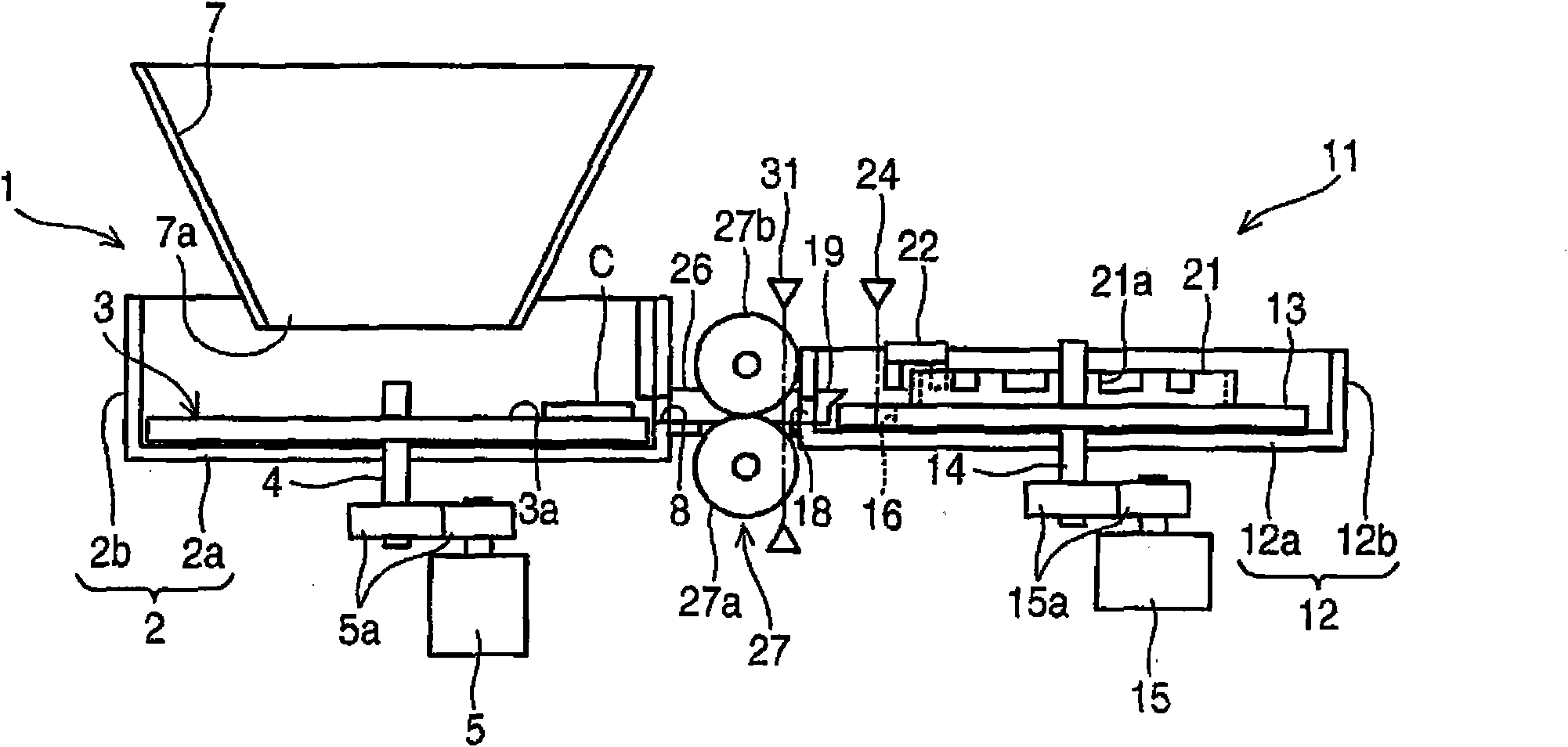

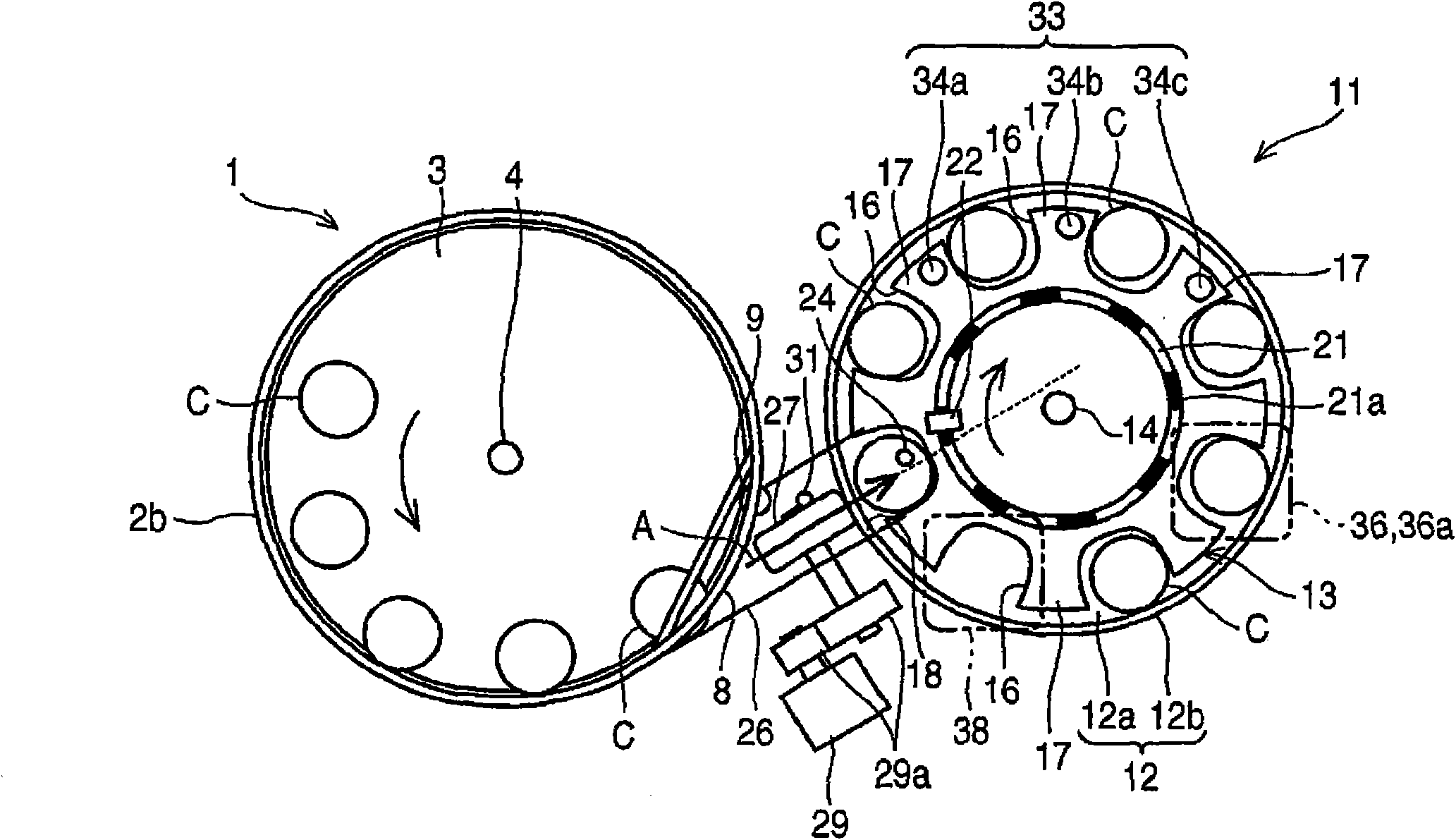

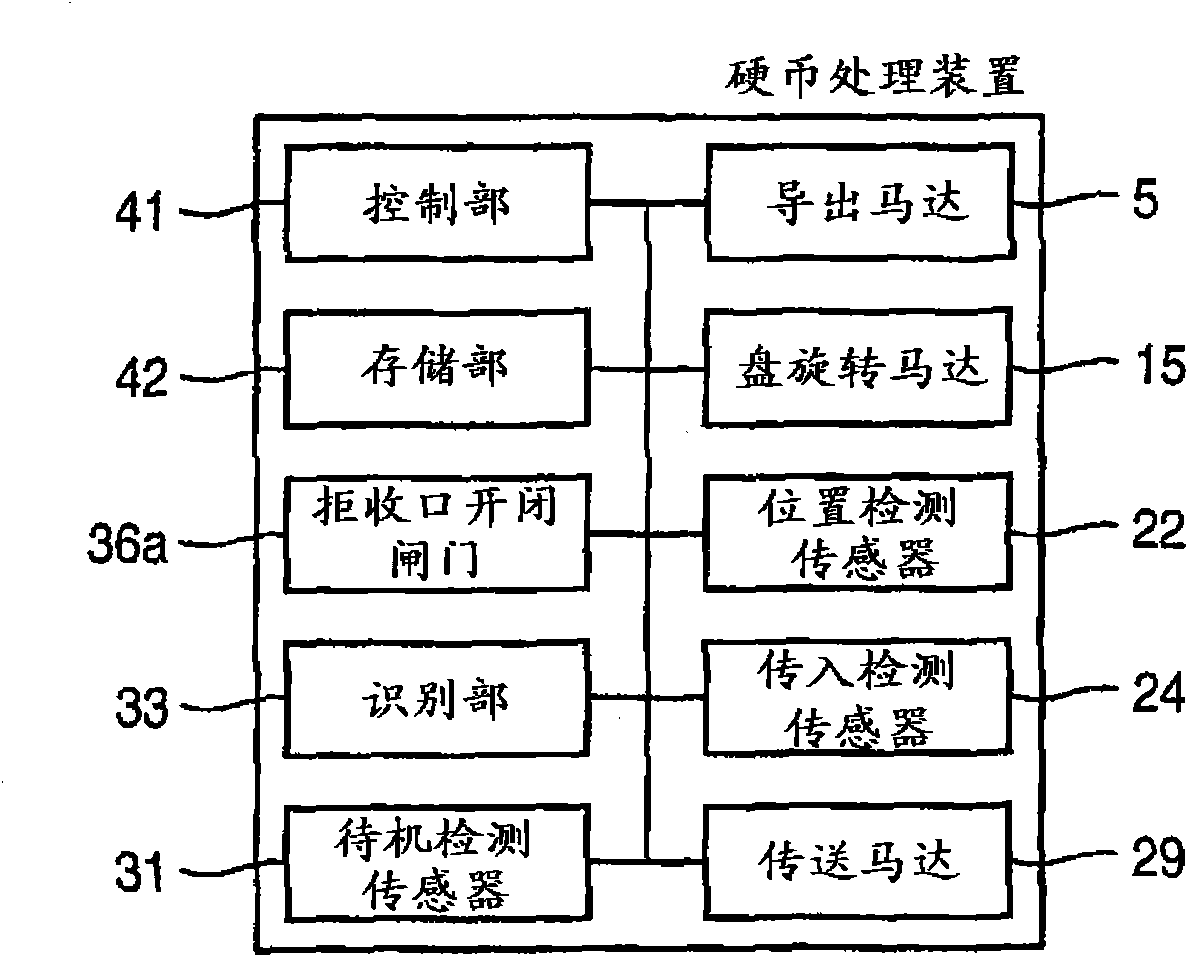

[0067] figure 1 , figure 2 Center 1 is the lead-out unit of the coin handling device.

[0068] 2 is the lead-out case of the lead-out unit 1, which is a bottomed cylindrical member having a height capable of accommodating approximately 100 or more coins C, and its bottom plate 2a is arranged horizontally.

[0069] 3 is a deriving rotary disk, which is horizontally arranged in the deriving housing 2, and is centered on the rotating shaft 4 supported in the center of the bottom plate 2a of the deriving housing 2 to the deriving direction ( figure 2The disk rotating in the counterclockwise direction) has a diameter such that a gap that cannot sandwich the coin C of the minimum thickness among the coins C to be processed is formed between the inner peripheral surface of the side wall 2b of the outlet case 2. The diameter is rotationally driven by the drive force transmitted from the lead-out motor 5 serving as a disk drive source to the rotary shaft 4 through the gear train 5...

Embodiment 2

[0154] Next, use Figure 10 and Figure 11 The coin handling device of this embodiment will be described.

[0155] In addition, the same parts as in the above-mentioned first embodiment are given the same symbols and their descriptions are omitted.

[0156] The coin handling apparatus of this embodiment has the same configuration as that of the first embodiment described above.

[0157] In addition, although the operation of the coin sorting process is the same as that of the above-mentioned embodiment 1 in principle, it is different from the above-mentioned embodiment 1 in that the following abnormal control is performed. Figure 5 As shown in the fifth coin C displayed, the control unit 41 temporarily stops feeding the conveying roller pair after passing the feeding end determination time T5 from when the feeding detection sensor 24 detects the fed coin C (ON). 27 of the drive, when using the standby detection sensor 31 to confirm the existence of the standby coin thereaf...

Embodiment 3

[0171] Next, use Figure 12 and Figure 13 The coin handling device of this embodiment will be described.

[0172] In addition, the same code|symbol is attached|subjected to the same part as the said Example 1, and the description is abbreviate|omitted.

[0173] The coin handling apparatus of this embodiment has the same configuration as that of the first embodiment described above.

[0174] In addition, it is different from the first embodiment in that the operation of the coin sorting process is changed in the stopping time of the drive of the conveyance plate 13 . Therefore, the intermittent driving in this embodiment is not intermittent driving of a fixed period, but non-periodic intermittent driving in which the driving of the stopped conveying tray 13 is started when the driving of the conveying roller pair 27 holding the waiting coins is stopped. In addition, the driving time of about one pitch of the coin storage unit 16 , that is, the driving time based on the stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com