Machining system and robot system

A processing system and robot technology, applied in the direction of metal processing machinery parts, metal processing, general control system, etc., can solve the problems of not being able to improve processing efficiency, achieve high-speed processing, improve processing efficiency, high-precision and processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

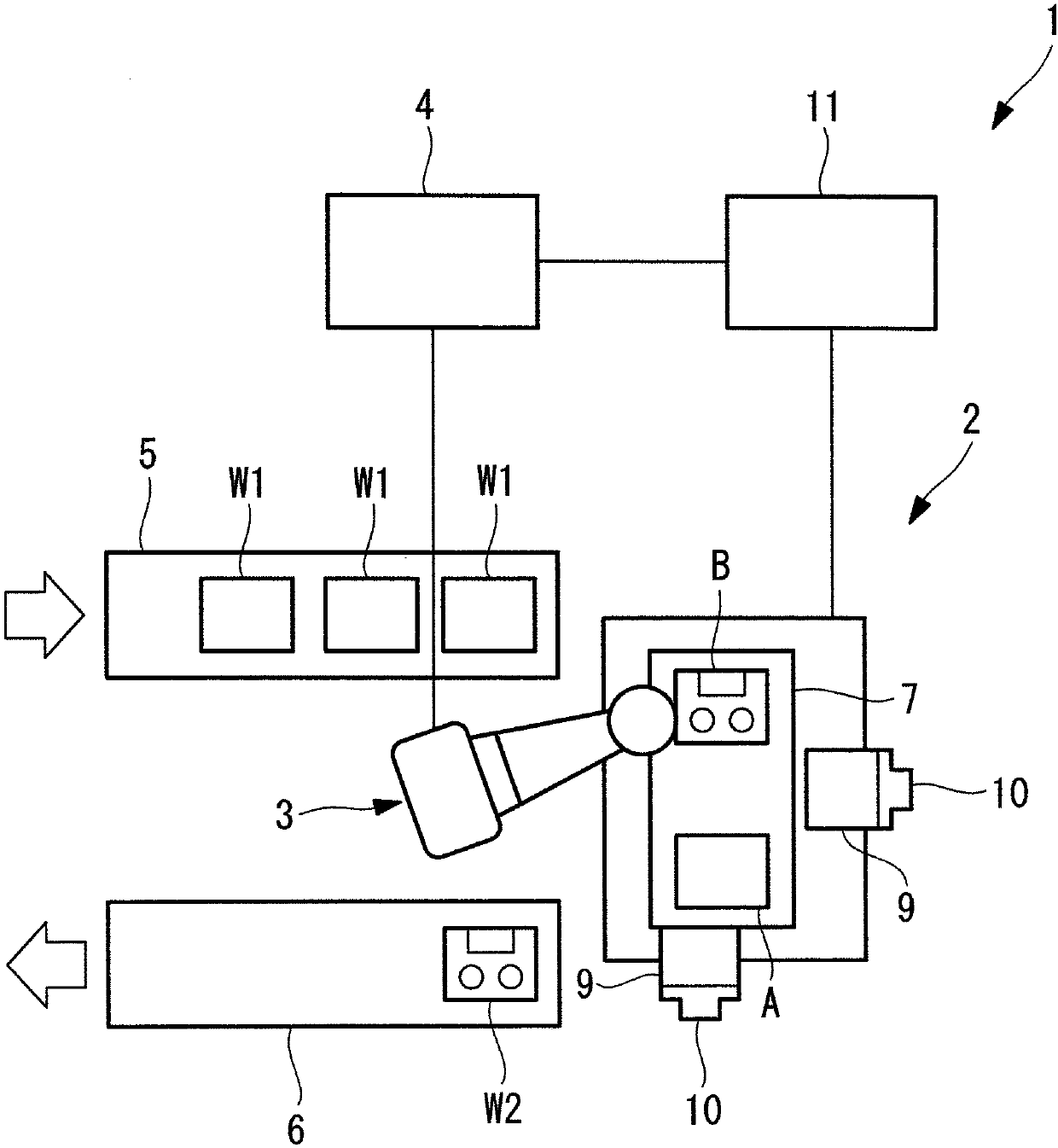

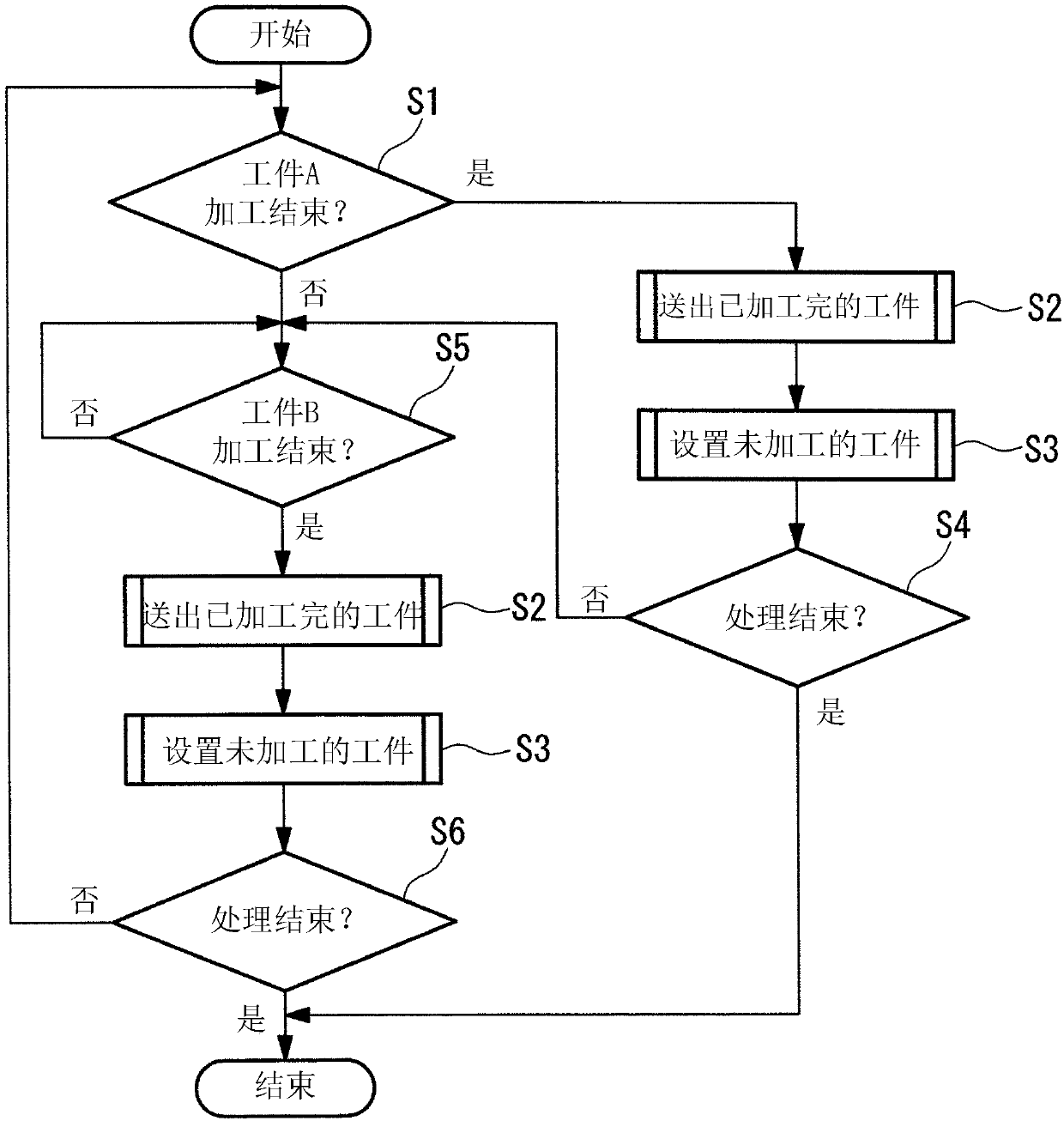

[0050] Next, a processing system 1 according to an embodiment of the present invention will be described with reference to the drawings.

[0051] The processing system 1 of the present embodiment is as figure 1 As shown, it includes: a machine tool 2, a robot 3, a robot control device (robot control unit) 4 for controlling the robot 3, a supply conveyor 5 for supplying an unprocessed workpiece W1, and a sending conveyor for sending out a processed workpiece W2. 6.

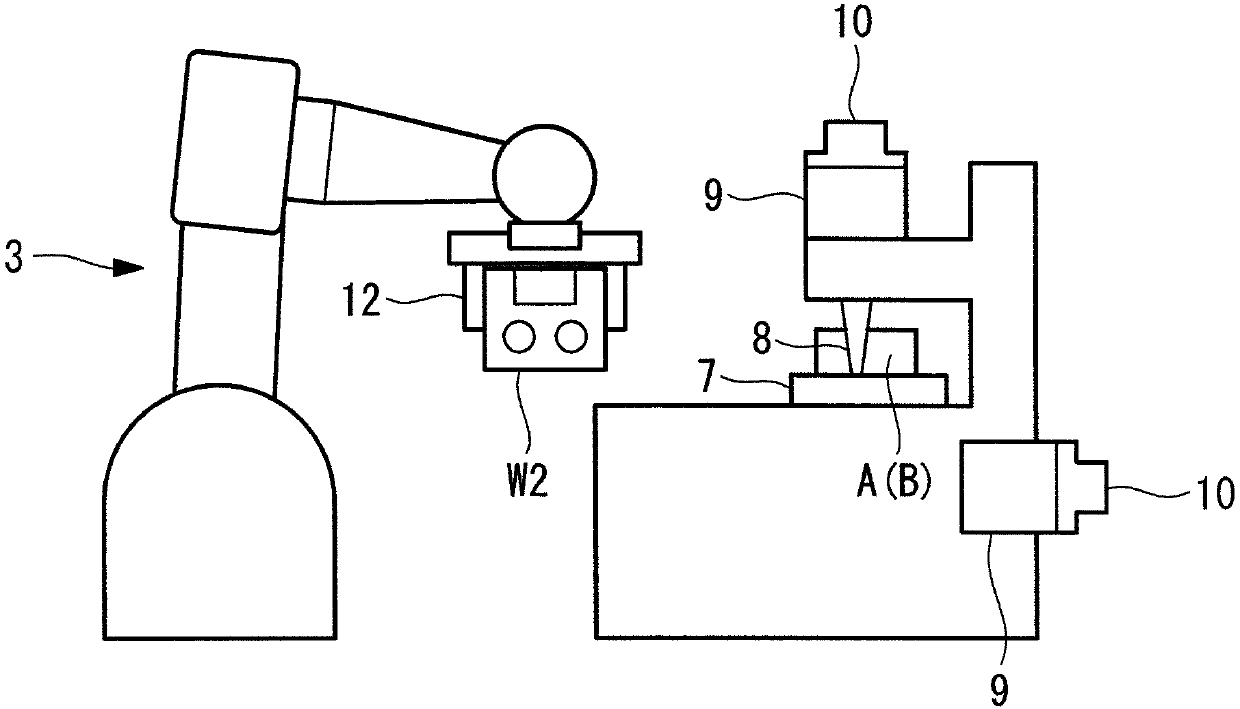

[0052] like figure 1 as well as figure 2As shown, the machine tool 2 is equipped with: a worktable 7, which fixes the workpiece W1 on the upper surface and moves the workpiece W1 in two horizontal directions; a tool shaft 8, which moves a tool such as a drill bit up and down along a vertical axis and makes the The drill blade rotates around the vertical axis; the motor 9 drives the table 7 and the tool shaft 8; the encoder 10 detects the rotation angle of each motor 9; 10 detected rotation angle to control eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com