Modular float mounting micro rectangular electric connector

An electrical connector, micro-rectangle technology, applied in the direction of connection, installation of connection components, components of connection devices, etc., can solve the problems of only one-to-one connection, processing error, inconvenient installation, etc., and achieve the effect of accurate connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

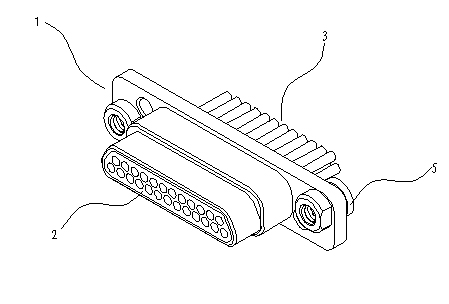

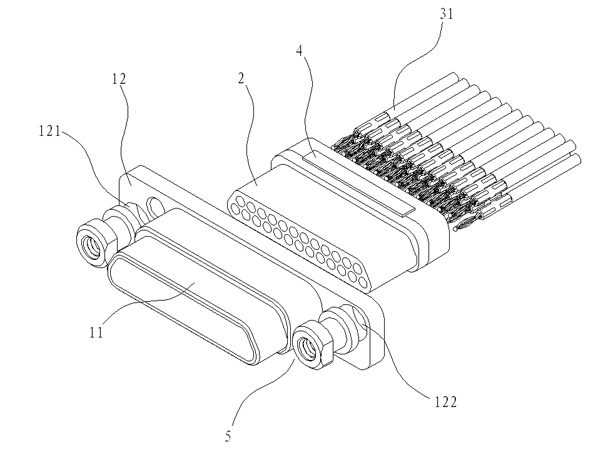

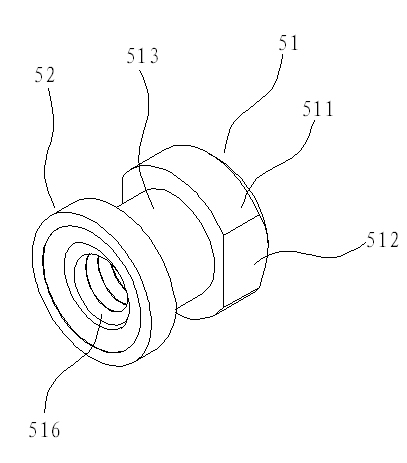

[0015] Figure 1-4 As shown, the modular floating micro-rectangular electrical connector mainly includes a housing 1 , an insulator 2 , a contact component 3 , epoxy glue 4 and a floating component 5 . The contact assembly 3 is formed by crimping high-temperature wires 31. The contact assembly 3 is fixed in the insulator 2 through epoxy glue 4. The insulator 2 passes through the large shell plate 12 of the shell 1 and the shell body 11 and is fixed in the shell 1. Left and right holes 121, 122 are respectively arranged on the large shell plate 12 at both ends of the outer casing 11. A floating assembly 5 is installed in the left and right holes. The floating assembly 5 includes a rivet sleeve 51 and a rivet pad 52. Shaft shoulder 514 is arranged, and the other end of rivet sleeve 51 is provided with anti-rotation boss 511, and the outer circular surface of anti-rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com