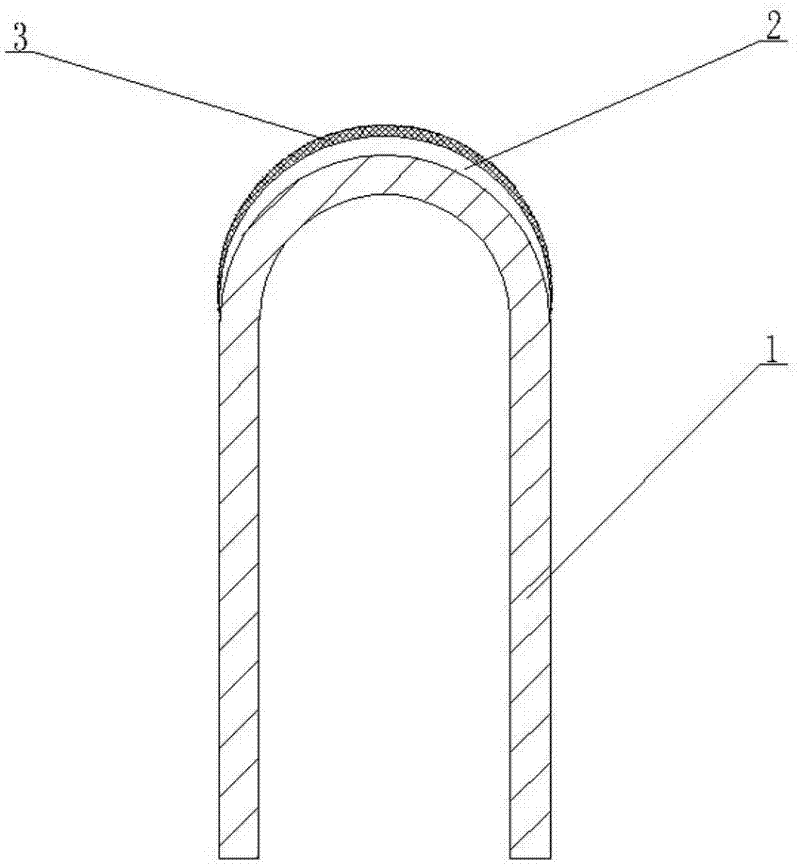

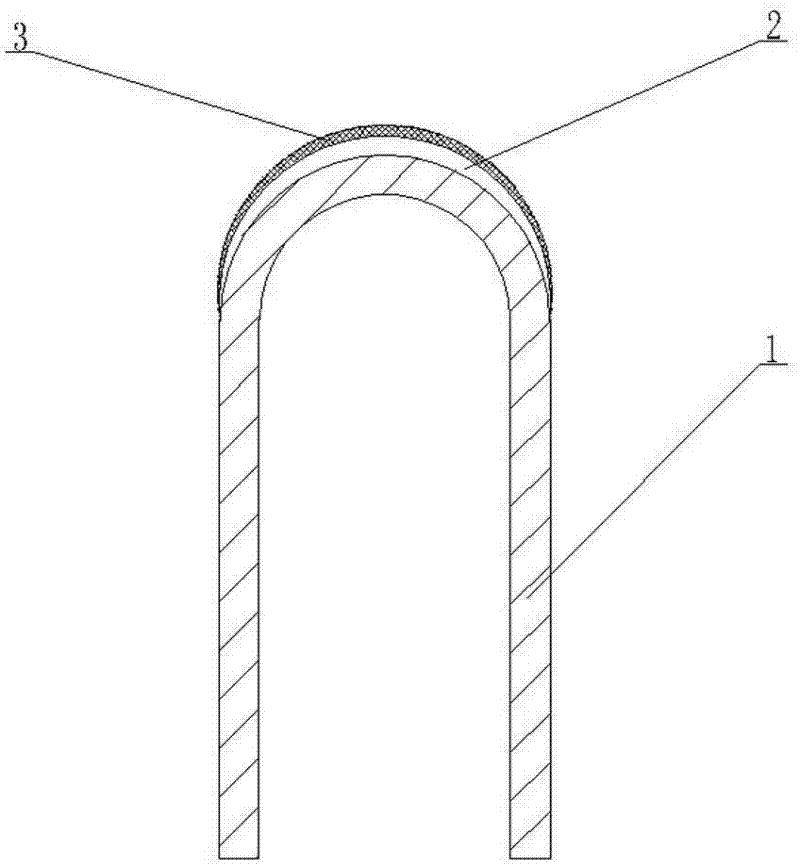

High-power ceramic output cap for microwaves and production method thereof

A production method and high-power technology, applied in the direction of microwave heating, etc., can solve the problems of uneven ceramic volume density, easy deformation of ceramic body, uneven force of ceramics, etc., so as to improve the pass rate of ceramics, avoid ceramic lack of porcelain, The effect of fast precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: A production method of a high-power ceramic output cap for microwaves, the proportion of its components is calculated in parts by weight, including the following process steps:

[0032] (1) Raw material ball mill: 90 parts of aluminum oxide, 1 part of calcium carbonate, 1 part of silicon oxide, 2 parts of kaolin, 1.5 parts of talcum powder, 1 part of zirconia, 5 parts of binder polyvinyl alcohol, 1 part of release type Agent stearate, 1 part of dispersant sodium polyacrylate and 1 part of defoamer polyester fiber are poured into a ball mill, and 60 parts of deionized water are added, and crushed at a speed of 30 rpm for 12 hours to obtain an average particle size It is a paste slurry of 1.5-10 microns; the paste slurry is dried with a spray granulation tower to obtain a granular powder with an average particle size of 40-60 microns;

[0033] (2) Raw material iron removal: put the granular powder obtained in step (1) into an iron removal device to remove ir...

Embodiment 2

[0040] Embodiment 2: A production method of a high-power ceramic output cap for microwaves, its component ratio is calculated in parts by weight, including the following process steps:

[0041] (1) Raw material ball milling: 94 parts of aluminum oxide, 2 parts of calcium carbonate, 2 parts of silicon oxide, 3 parts of kaolin, 2.5 parts of talcum powder, 2 parts of zirconia, 9 parts of binder polyvinyl alcohol, 2 parts of release type Agent stearate, 3 parts of dispersant sodium polyacrylate and 2 parts of defoaming agent polyester fiber are poured into a ball mill, and 70 parts of deionized water are added, and crushed at a speed of 40 rpm for 10 hours to obtain an average particle size It is a paste slurry of 1.5-10 microns; the paste slurry is dried with a spray granulation tower to obtain a granular powder with an average particle size of 40-60 microns;

[0042] (2) Raw material iron removal: put the granular powder obtained in step (1) into an iron removal device to remove...

Embodiment 3

[0049] Embodiment 3: A kind of production method of high-power ceramic output cap for microwave, its component ratio is counted by weight parts, comprises the following process steps:

[0050] (1) Raw material ball mill: 92 parts of aluminum oxide, 1.5 parts of calcium carbonate, 1.5 parts of silicon oxide, 2.5 parts of kaolin, 2 parts of talcum powder, 1.5 parts of zirconia, 7 parts of binder polyvinyl alcohol, 1.5 parts of release type Agent stearate, 2 parts of dispersant sodium polyacrylate and 1.5 parts of defoamer polyester fiber are poured into a ball mill, and 65 parts of deionized water are added, and the average particle size is obtained by pulverizing at a speed of 35 rpm for 11 hours It is a paste slurry of 1.5-10 microns; the paste slurry is dried with a spray granulation tower to obtain a granular powder with an average particle size of 40-60 microns;

[0051] (2) Raw material iron removal: put the granular powder obtained in step (1) into an iron removal device ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com