Device for cleaning a roll of a rolling mill

A technology of cleaning device and nozzle, applied in the field of backup rolls or work rolls, and the roll field of skin-pass mills (laminoir skin-pass), which can solve the problems of increased waste, waste of cleaning liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

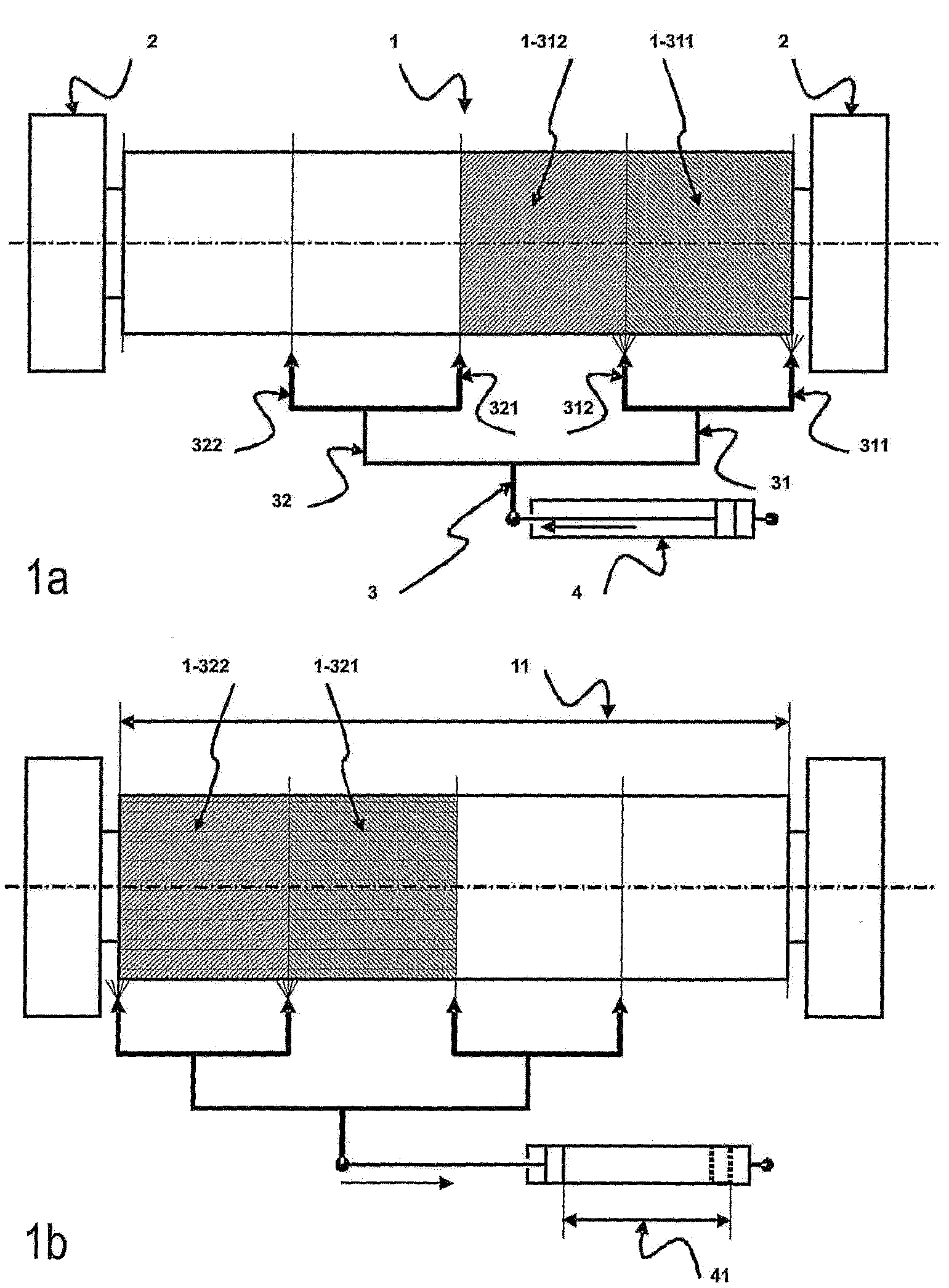

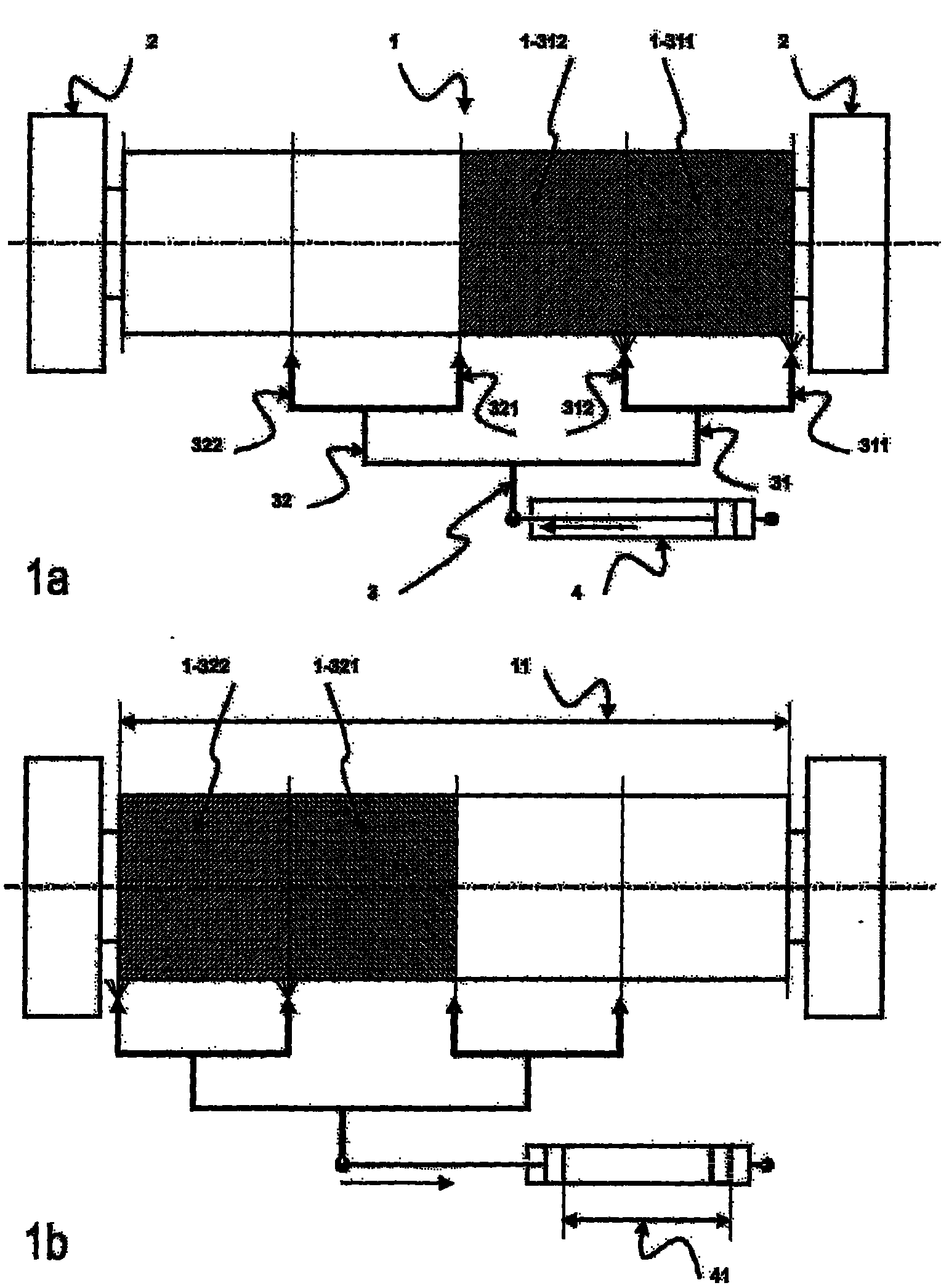

[0021] The figure is divided into two parts 1a and 1b. These two parts show the mill roll 1 supported by bearings 2 . The cleaning device 3 can move towards the roller 1 parallel to the axis 5 of the roller 1 under the action of the jack 4 . The cleaning device 3 comprises two supports 31 and 32 which each ensure the supply of cleaning liquid to four nozzles 311 , 312 and 321 , 322 which are divided into A pair of nozzles and a second pair of nozzles are provided on each of said two supports 31 , 32 .

[0022] During the extended phase of the jack 4 shown in part 1a of said figure, the two first nozzles 311, 312 work and respectively clean the first zone 1-311 and the second zone 1-312 of the roll, said The two areas are juxtaposed. The second pair of nozzles 321, 322 are inactive.

[0023] During the retraction phase of the jack 4 shown in part 1b of the figure, the second pair of nozzles 321, 322 work and respectively clean the third zone 1-321 and the fourth zone 1-322 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com