Improved rotary disk type potato harvester

A turntable type, potato technology, applied in the direction of digging harvesters, harvesters, excavators, etc., can solve the problems of high cost of use, slow separation speed, heavy body, etc., to prolong the service life of the machine and not easily damaged by the machine , fast and fully separated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

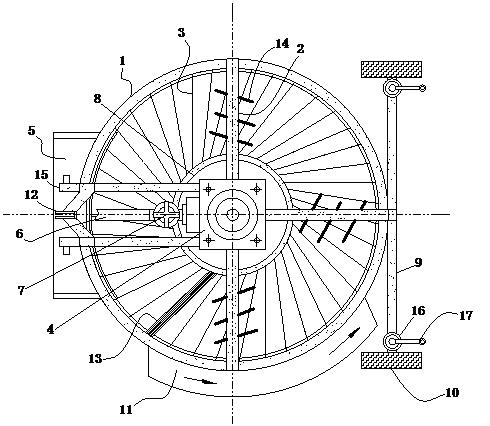

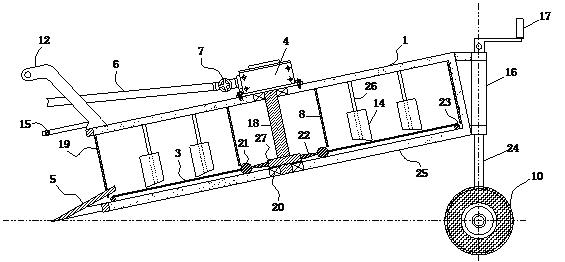

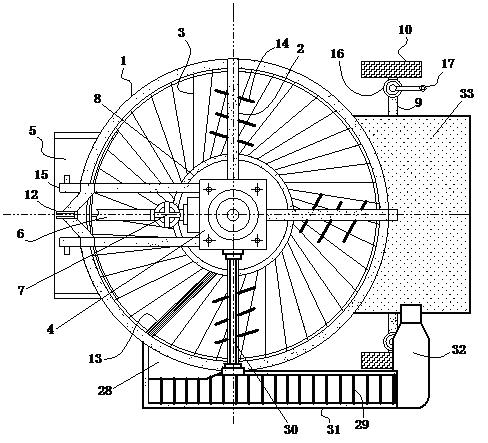

[0018] Below in conjunction with accompanying drawing, the practical invention is described in detail.

[0019] see figure 1 and figure 2 Among them, an improved turntable potato harvester mainly includes a built-in turntable separation mechanism in a disc-type frame body, a transmission mechanism is installed on the upper end, and an inclination adjustment mechanism is connected to the rear end of the disc-type frame body. It is characterized in that: the disc-type The frame body includes an upper disk support 1 connected to a circular body through a support frame 2 and a lower end disk support 25, and several support frames 2 are respectively arranged in the disks of the upper end disk support 1 and the lower end disk support 25. Connected with each other, on the disk of the upper end disk support 1 and the lower end disk support 25, the inner circle guard plate 8 and the outer circle guard plate 19 are welded again, and an input port and a Digging shovel 5, the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com