Built-in main-splicing clamp for car body

A car body and fixture technology, applied in auxiliary devices, manufacturing tools, auxiliary welding equipment, etc., can solve problems such as affecting the proximity of welding tongs, difficult to achieve flexible production, etc., to solve the bottleneck of production scale, avoid repeated construction, and close Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

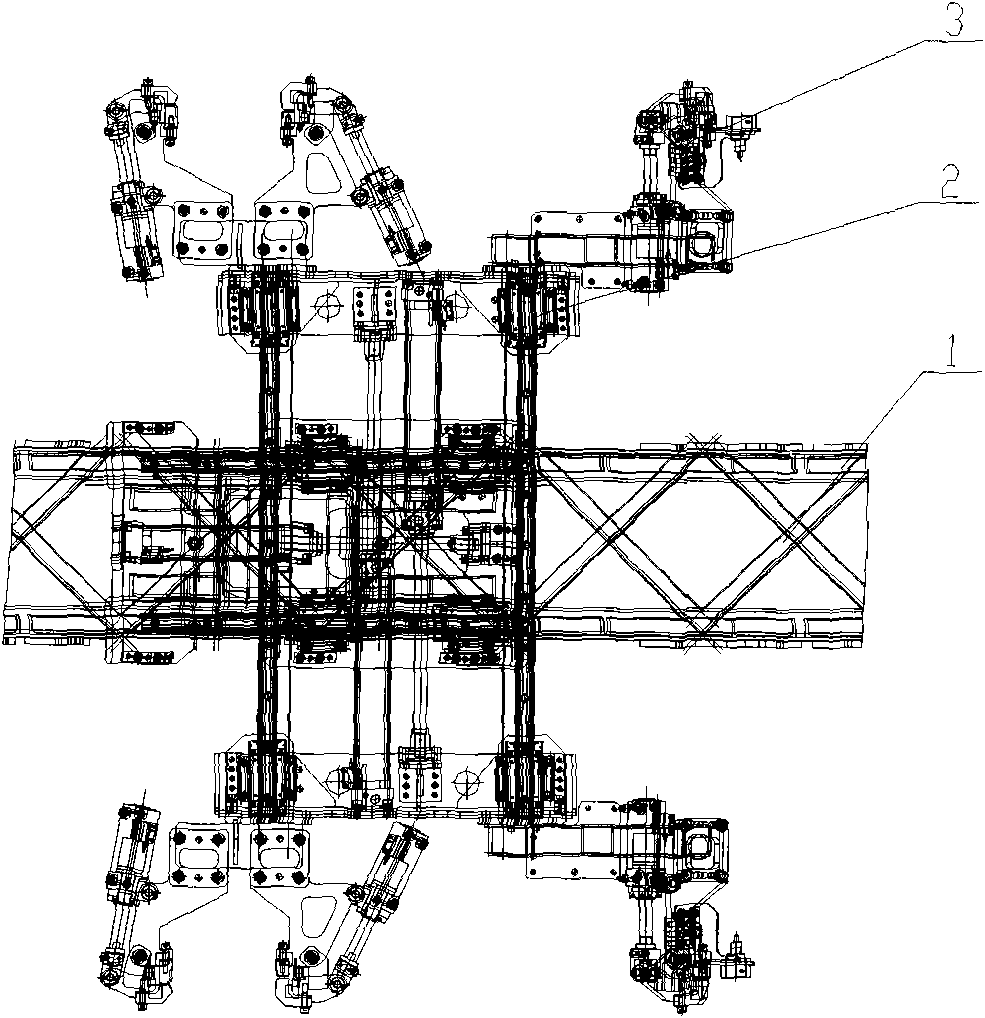

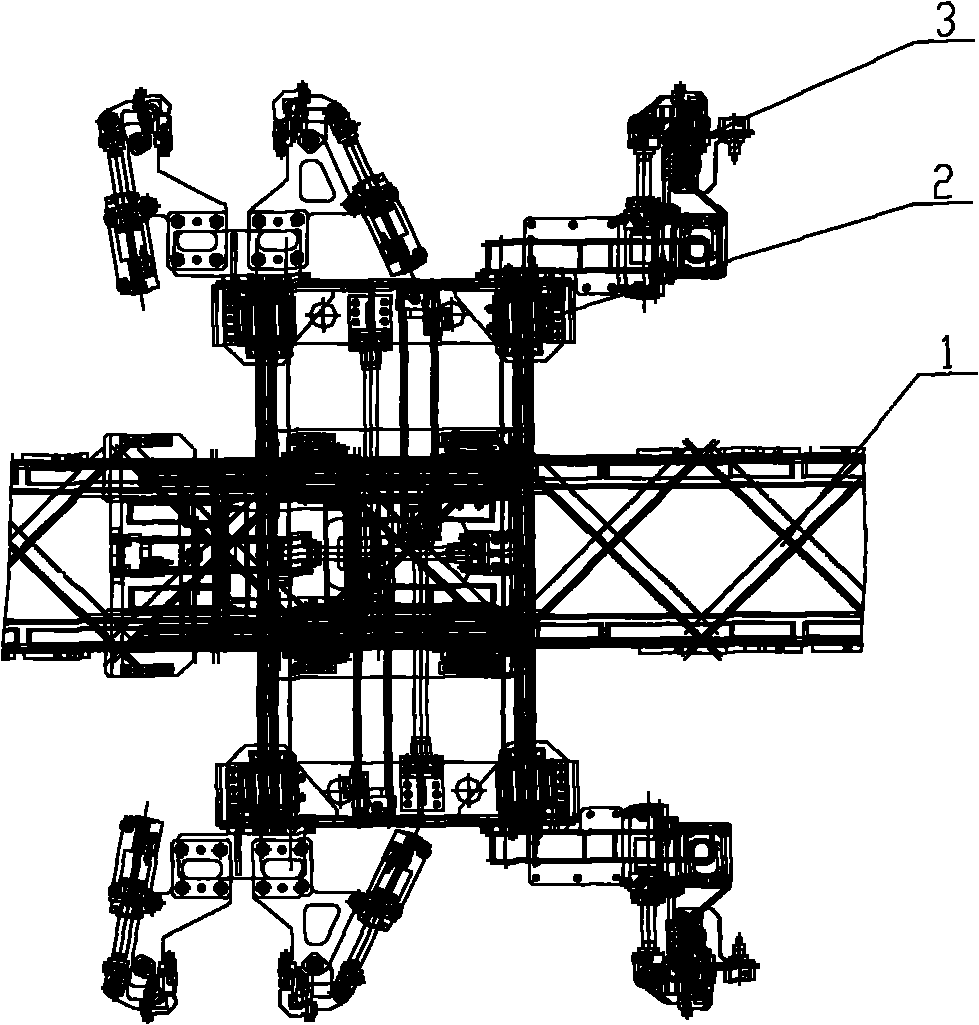

[0013] Below in conjunction with accompanying drawing, the present invention will be further described: as figure 1 As shown, the built-in main jig of a car body is characterized in that it is composed of a built-in jig body and a lower jig of the vehicle body, wherein the built-in jig body is composed of a jig body skeleton 1, an opening mechanism 2, and a body positioning clamping part 3, and the body positioning The clamping part 3 is fixedly connected to the opening mechanism 2, and the opening mechanism is fixedly connected to the framework of the clamp body 1, connected with the lifting mechanism and suspended in the air; the lower clamp of the vehicle body is clamped by the positioning clamping part of the vehicle body and the positioning of the built-in clamp body The mechanism is composed of a built-in clamp body that is located on the ground and connected with the lifting mechanism.

[0014] At the previous station of the main assembly station, after the pre-assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com