Paper feeding roll with non-bloomed surface

A technology of paper feed roller and rubber roller, which is applied in the directions of pile separation, layered products, transportation and packaging, etc., can solve the problem of frost spray on the surface of the paper feed wheel, and achieve the effect of reducing frost spray and excellent wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

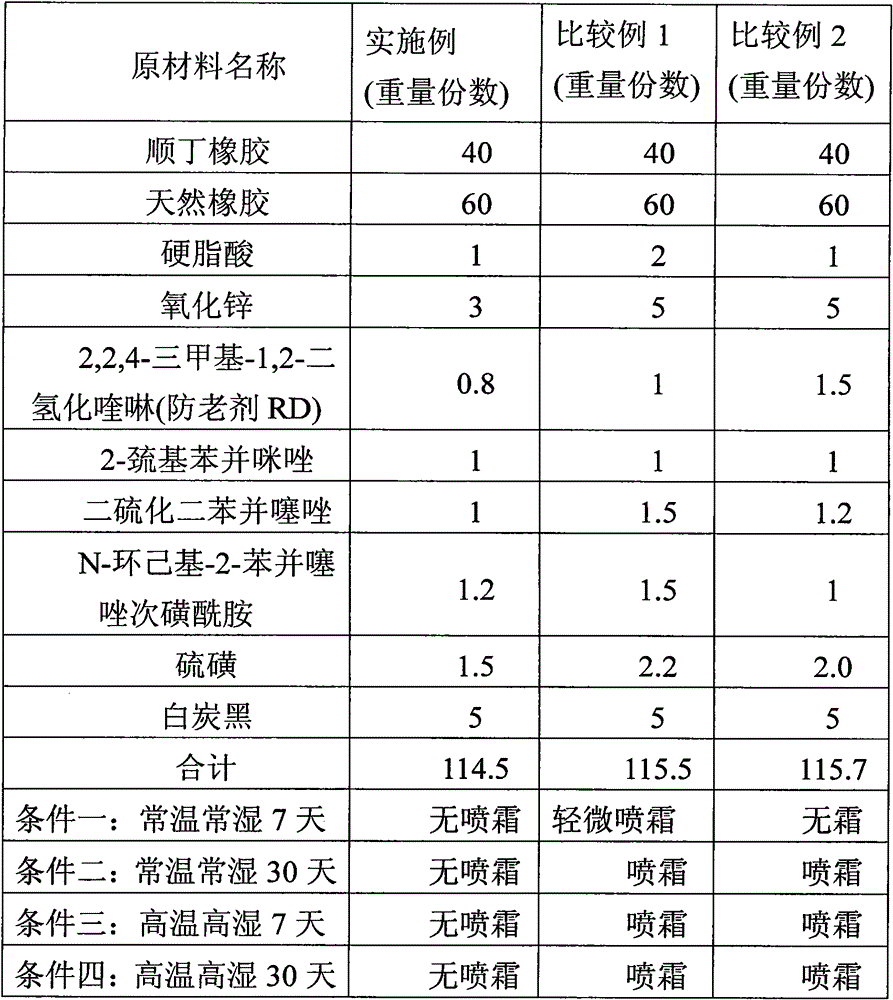

[0026] Table 1 is a specific embodiment of the present invention and two prior art (comparative example 1 and comparative example 2) formula and performance test method, data, the content of various compositions can be in the technical scheme of above-mentioned summary of the invention part Test options within the range mentioned in order to obtain products with better performance.

[0027] Table 1

[0028]

[0029] The raw materials used in the above rubber composition are all commercially available products.

[0030] Butadiene rubber and natural rubber in Table 1 can also be used alone.

[0031] The making of paper feed wheel (cover) of the present invention adopts well-known rubber production technology to carry out. The various components in the rubber composition are mixed according to the usual process, and then molded into a long tube shape. The molding temperature is 150°C. The vulcanization time depends on the amount of the vulcanization system. Usually, the vulc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com