Vehicle transporting manipulator adopting gear-type clamping mechanism

A technology of clamping mechanism and manipulator, which is applied in the field of automobile handling equipment and automobile handling manipulator, can solve the problems of large and complex overall equipment, increase the operation procedure and time of entering and exiting the car, so as to improve the possibility, solve the problem of two-way entering and exiting the car, and be reliable. sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific drawings and embodiments.

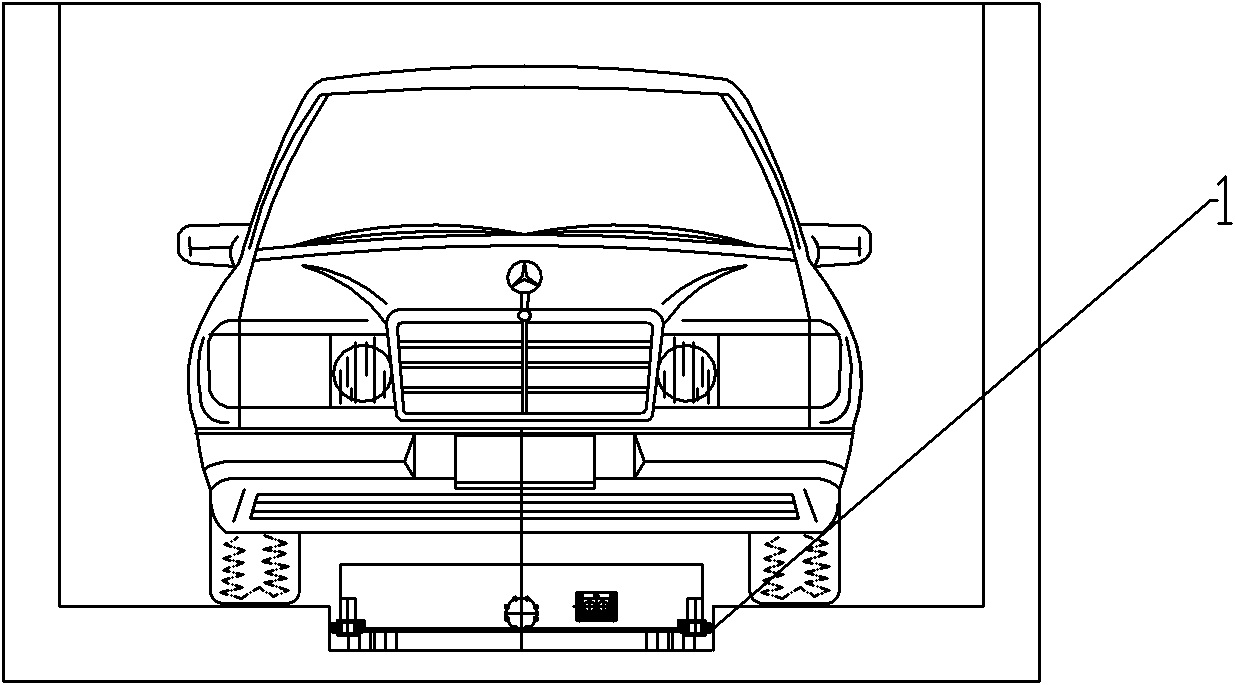

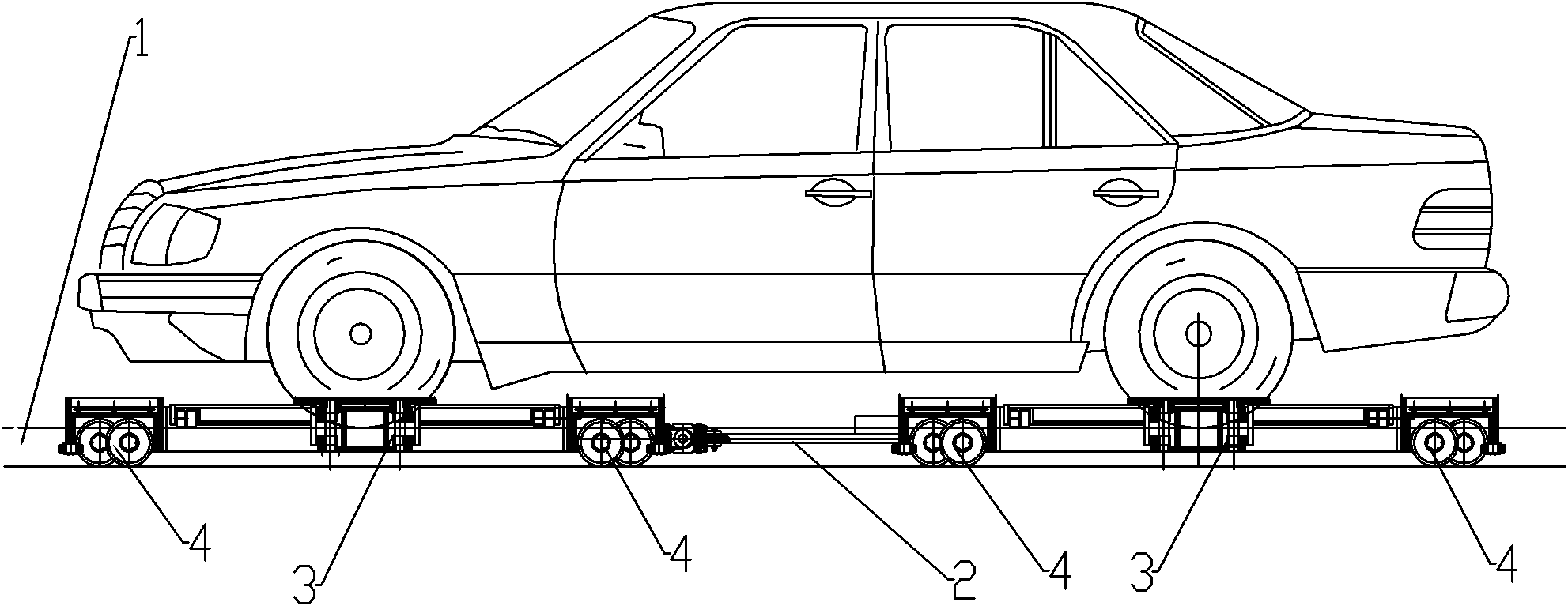

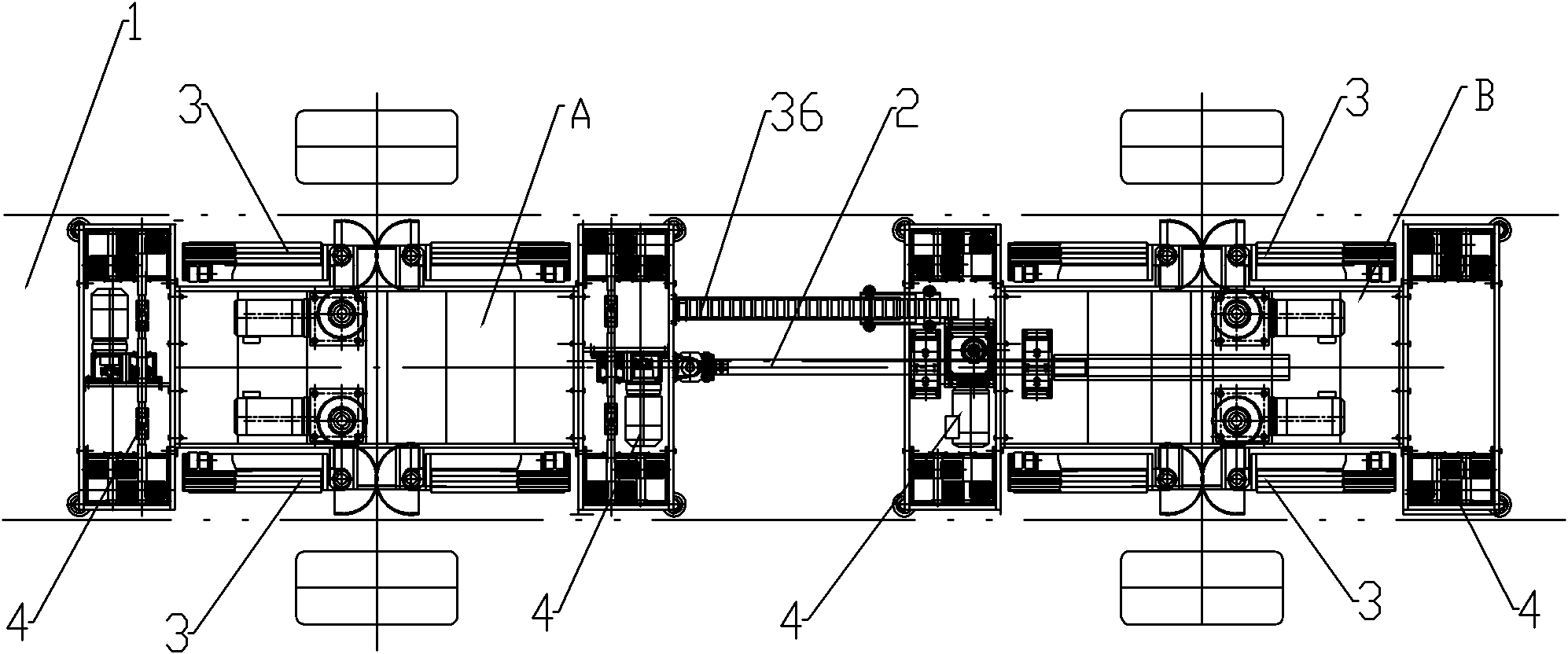

[0036] The present invention proposes a manipulator that adopts a gear-type clamping mechanism to carry a car, and its overall layout is as follows: Figure 1.1~Figure 1.3 As shown, the working channel 1 of the manipulator is arranged on the warehouse position, and the working channel 1 is a shallow ditch about 100 mm lower than the parking space and about 1000 mm wide. The car handling manipulator works in the working channel 1 under the chassis of the car, and it is mainly composed of a front car body A and a rear car body B. The front car body A and the rear car body B are respectively connected to a pair of front wheels and a pair of The rear wheels are correspondingly matched; the front body A and the rear body B each have an independent running mechanism 4 and a clamping mechanism 3; a distance adjustment mechanism 2 is arranged between the front body A a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com