Equipment calibration method and output device

A calibration method and equipment technology, applied in the field of color management, can solve problems such as different, inability to adapt to equipment calibration requirements, and 4 curves that cannot consider CMYK correlation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

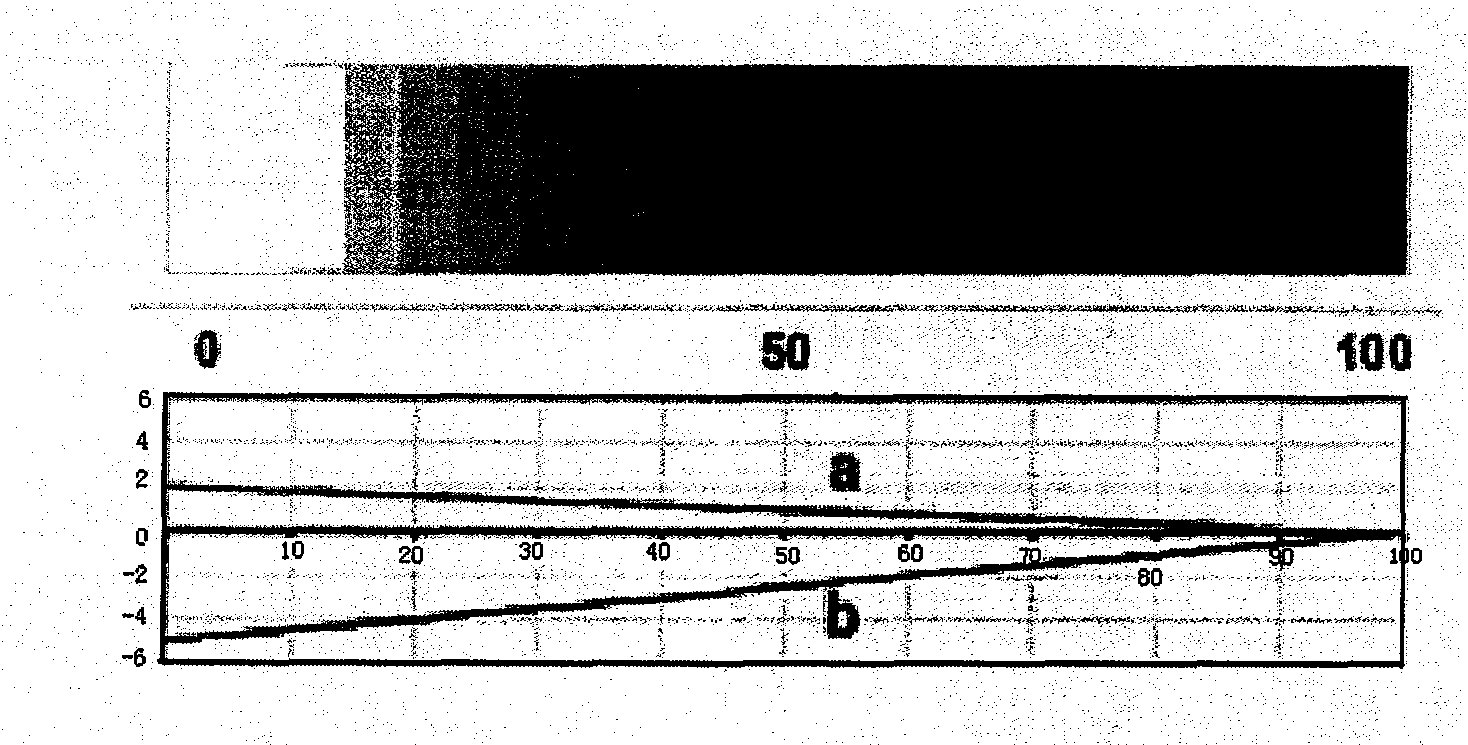

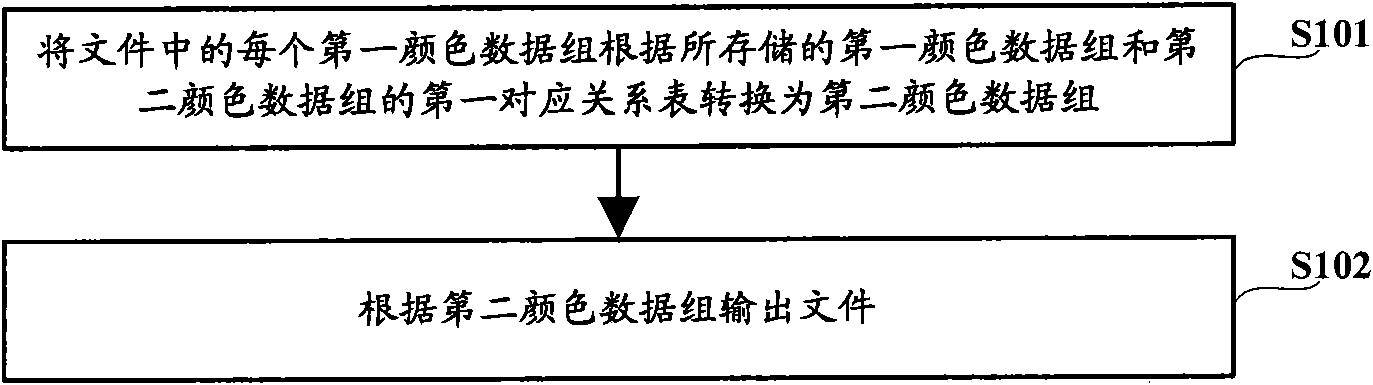

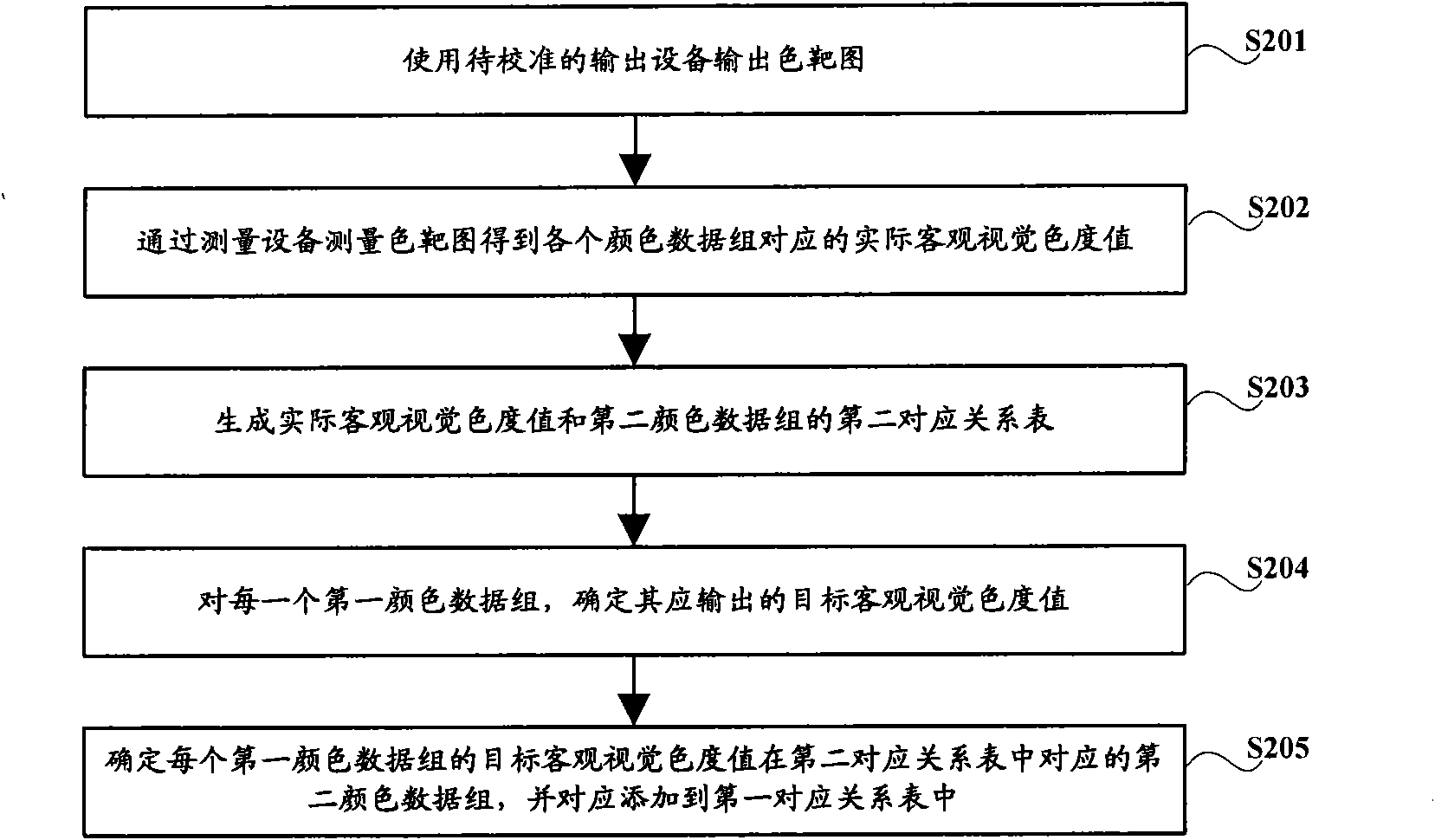

[0044] An embodiment of the present invention provides an equipment calibration method and an output device. Before calibrating the equipment, the color target map is output, and the second color data group and the actual objective visual chromaticity value are obtained by measuring the objective visual chromaticity value of the color target map. Correspondence table, then for each first color data group, look for the actual objective visual chromaticity value that is equal to the target objective visual chromaticity value that the color data group should output, obtain the corresponding relationship table and the first color data group should Output the second color data set corresponding to the Lab measured value equal to the target Lab value, and associate the first color data set with the second color data set to form the color of the first color data set and the second color data set The data group correspondence table, so that when the file is output, the color data group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com