Cover membrane for printed circuit board

A printed circuit board and cover film technology, applied in the direction of printed circuit components, etc., can solve the problems of poor tensile strength, dimensional stability, high cost of black polyimide film 21, non-compliance with requirements, etc., and achieve excellent resistance. The effect of folding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

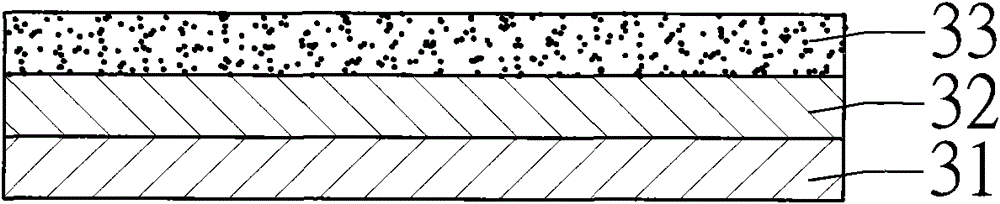

[0016] Embodiment: a kind of cover film for printed circuit board, such as image 3 As shown, it includes a core layer 32, a black composite material layer 33 with a low refractive index and an adhesive layer 31 for adhering the cover film to a printed circuit board, the core layer is fixedly sandwiched between the composite material layer and the between the adhesive layers.

[0017] In order for the covering film of this example to have the function of shielding the circuit pattern, the composite material layer includes a black substance. The cover film is composed of a mixture of resin, black substance and inorganic filler, wherein the resin is epoxy resin, the black substance is a mixture of one or more selected from black pigments, carbon powder or carbon nanotubes, and the inorganic filler is selected A mixture of one or more of titanium dioxide, boron nitride and barium sulfate. In order to maintain the folding resistance and scratch resistance of the composite materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com