Device for the tensioning of a leno thread for a doup heddle device for a weaving machine

An equipment and heddle technology, applied in the field of looms, can solve the problems of insufficient compensation for high tension changes, complex structures, etc., and achieve the effect of reducing the risk of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

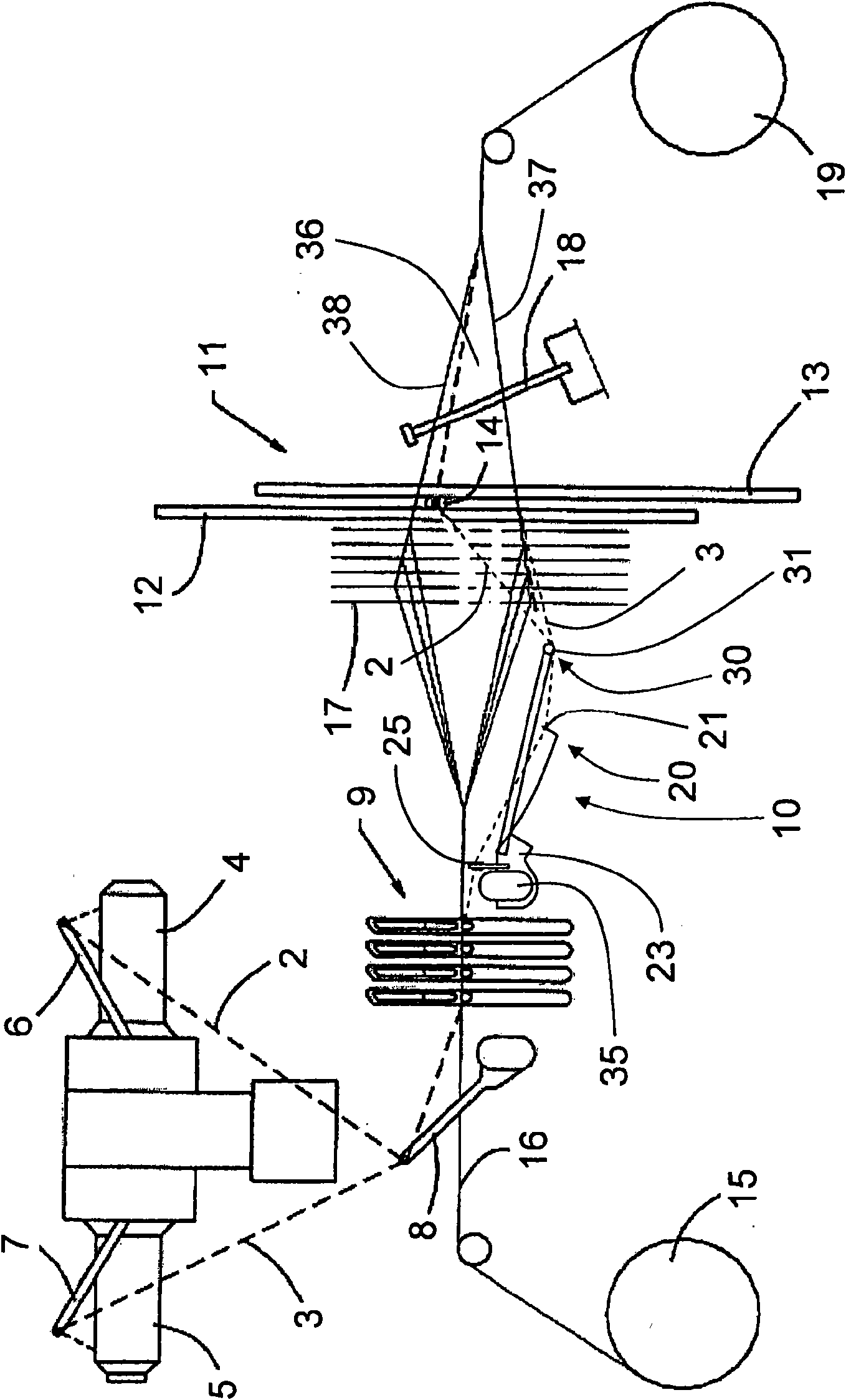

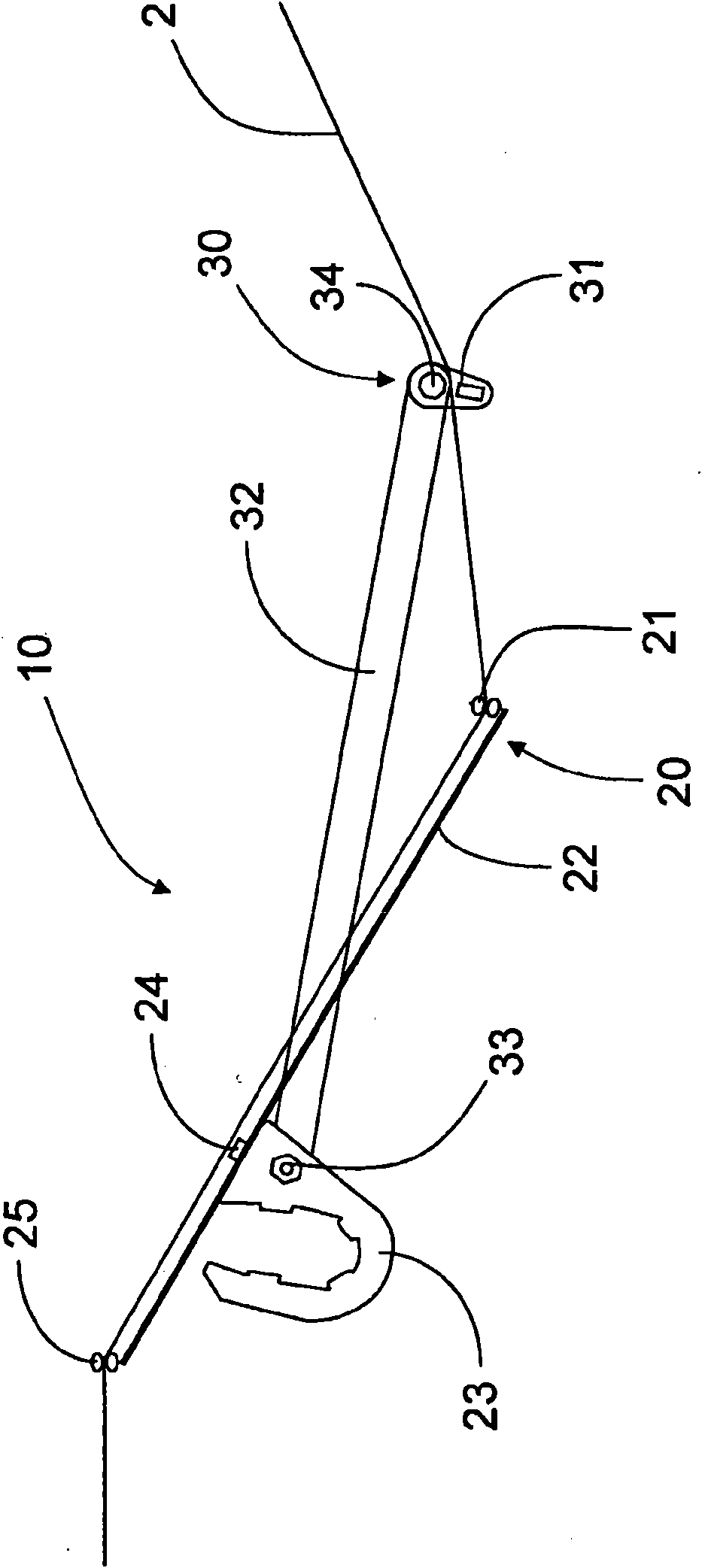

[0021] in figure 2 In the loom shown, the two leno threads 2 and 3 pass through the thread compensator 6 or 7, the fixedly positioned thread guide 8, the warp automatic stop device 9, and the device 10 according to the present invention each from a thread supply The spool (for example, the spool 4 or 5) is brought to the heddle device 11. It can be seen from DE3818680 C1 that the twisted heddle device 11 can be composed of two lifting heddles 12 and 13, and the lifting heddles 12 and 13 can interact with the twisted heddle 14, so that each lifting heddle 12, 13 can lift the twisted heddle 14. The warp beam 15 with the warp threads 16, the shed forming device 17, the reed 18, and the cloth shaft 19 are also schematically shown. The leno thread 2 guided through the twisted heddle 14 is also called a fixed leno thread, while the leno thread 3 guided around the twisted heddle 14 and between the associated lifting heddles 12, 13 is also called an alternating leno thread. Line or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com