Robot arm part

一种机器人臂、部件的技术,应用在爪臂、机械手、机械设备等方向,能够解决体积庞大、不便安装、结构复杂等问题,达到体积小、便于安装、传动平稳的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

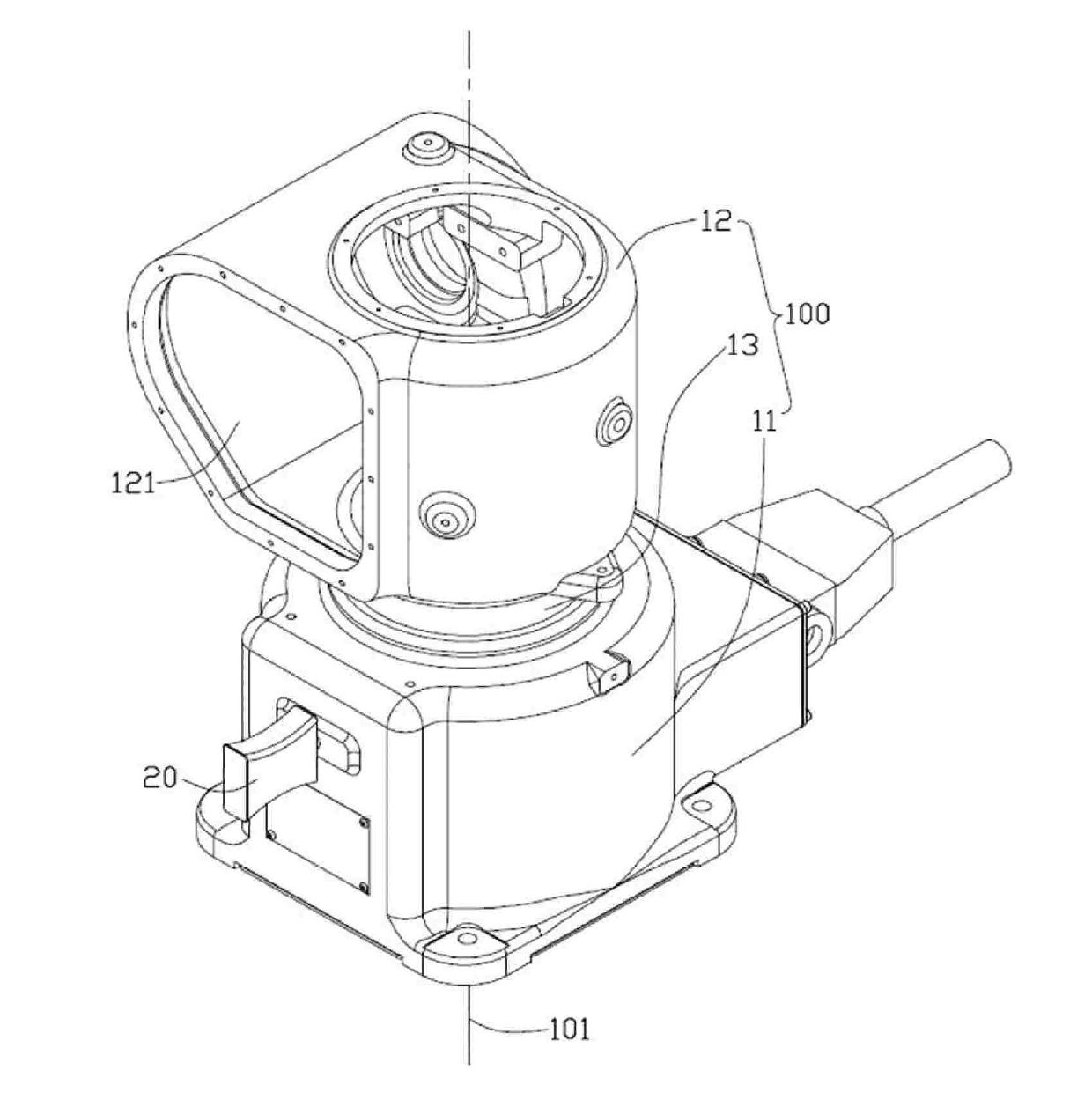

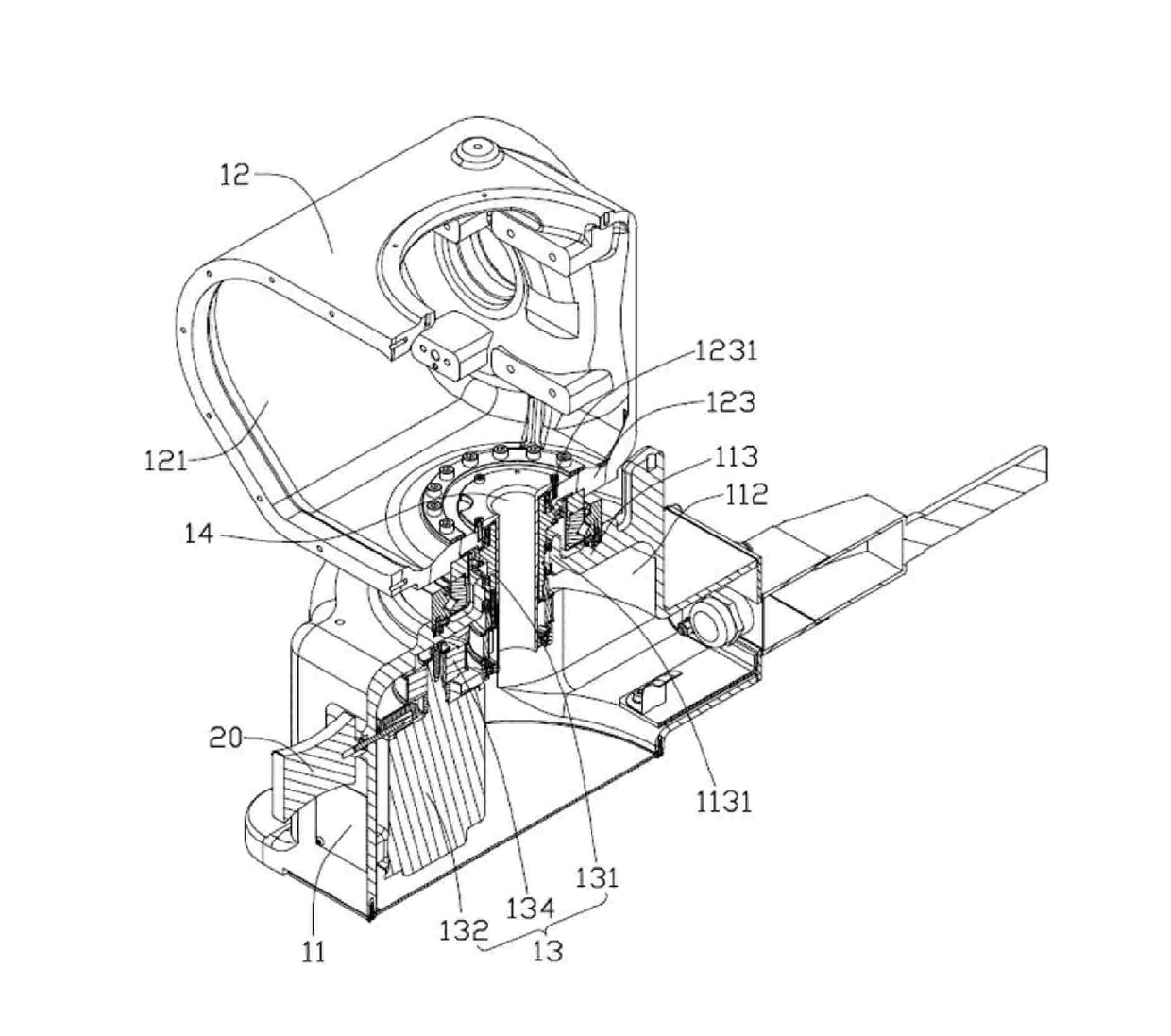

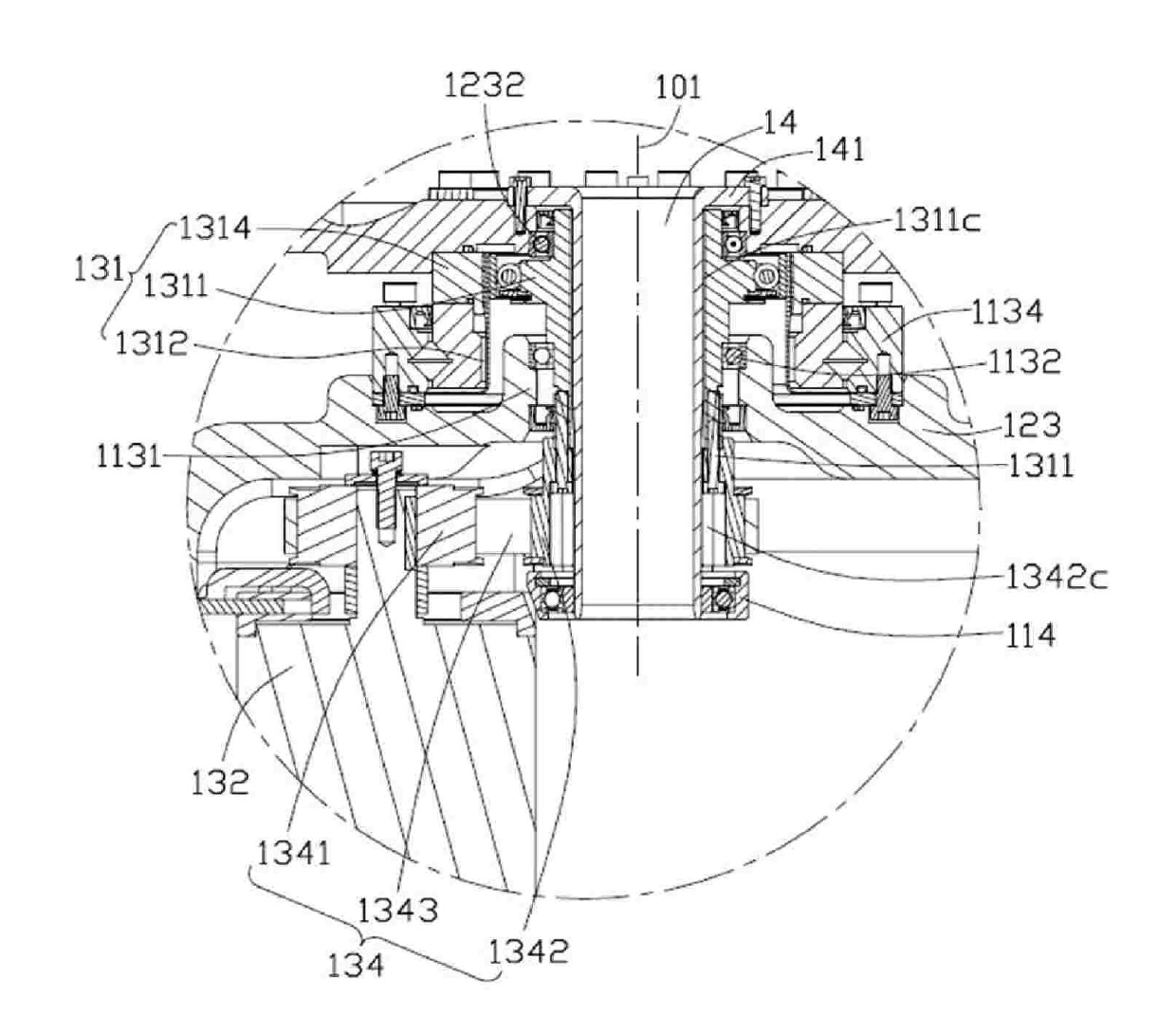

[0012] The robot arm component of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] see figure 1 and figure 2 , the robot arm part 100 according to the embodiment of the present invention includes a first hollow arm part 11 , a second hollow arm part 12 and a connection joint 13 connecting the first hollow arm part 11 and the second hollow arm part 12 . The second hollow arm part 12 is rotatable relative to the first hollow arm part 11 about the rotation axis 101 . The robot arm part 100 of this embodiment can be applied to a rotating structure of a six-axis robot near its base portion.

[0014] Both the first hollow arm portion 11 and the second hollow arm portion 12 are substantially cylindrical shells, and respectively have a first hollow portion 112 and a second hollow portion 121 . The first hollow arm portion 11 includes a first installation wall 113 , and the second hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com