Polypropylene resin composition for creating fabric texture

一种聚丙烯树脂、织物纹理的技术,应用在运输和包装、车辆部件等方向,能够解决纤维素纤维缠结尺寸减小、降低塑料零件质量、加工成本增加等问题

Active Publication Date: 2011-06-08

HYUNDAI MOTOR CO LTD +2

View PDF3 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the secondary process leads to entanglement of the cellulose fibers and a reduction in their size, so when the resulting resin is used in plastic parts for vehicle interior parts with an embossed surface, the texture of the fabric is reduced, instead due to the additional process Increased processing costs

In addition, the existing cellulose fibers or synthetic cellulose fibers are carbonized at about 250°C, so the cellulose fibers are burned or discolored during the injection molding of plastic parts, thus degrading the quality of the plastic parts

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

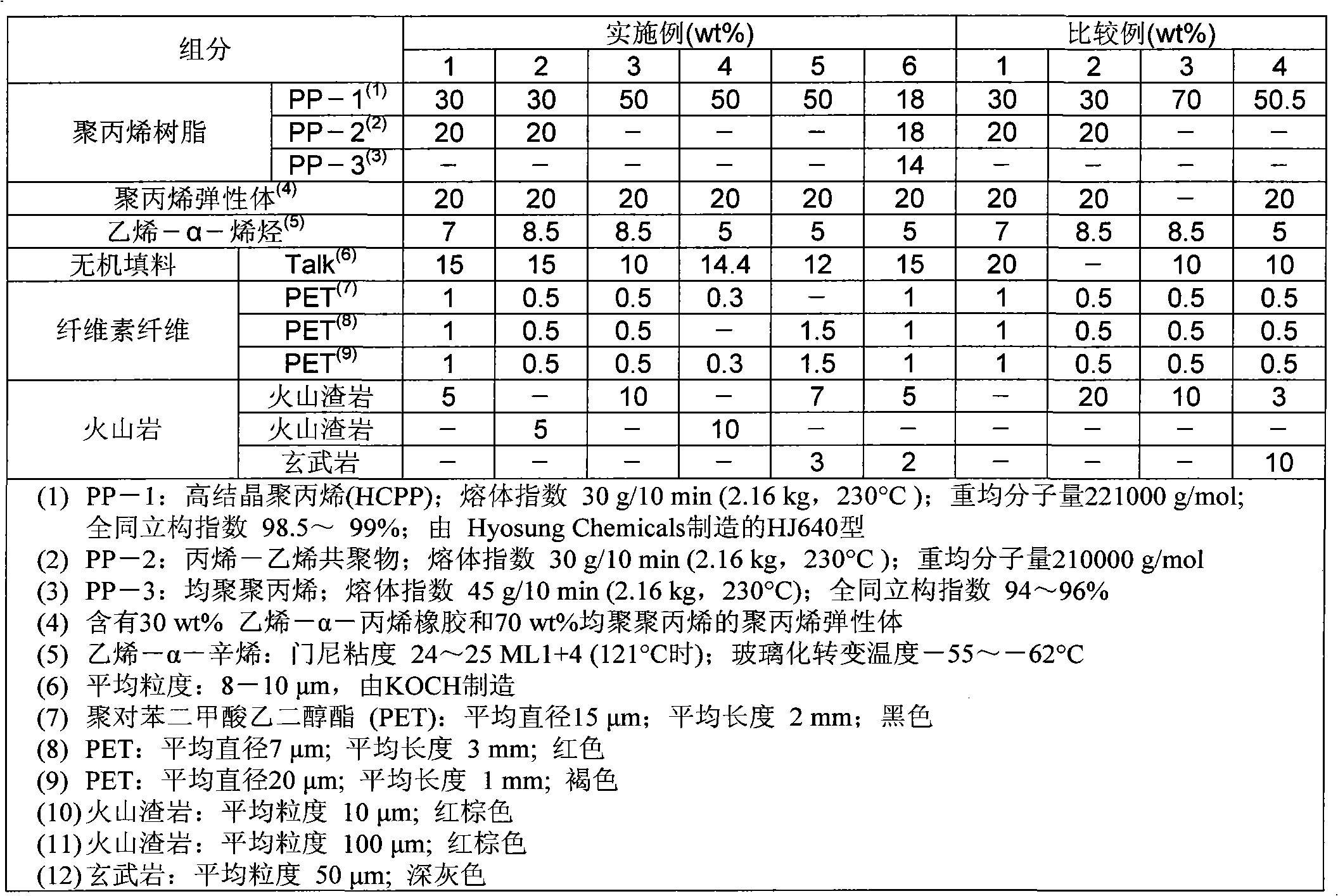

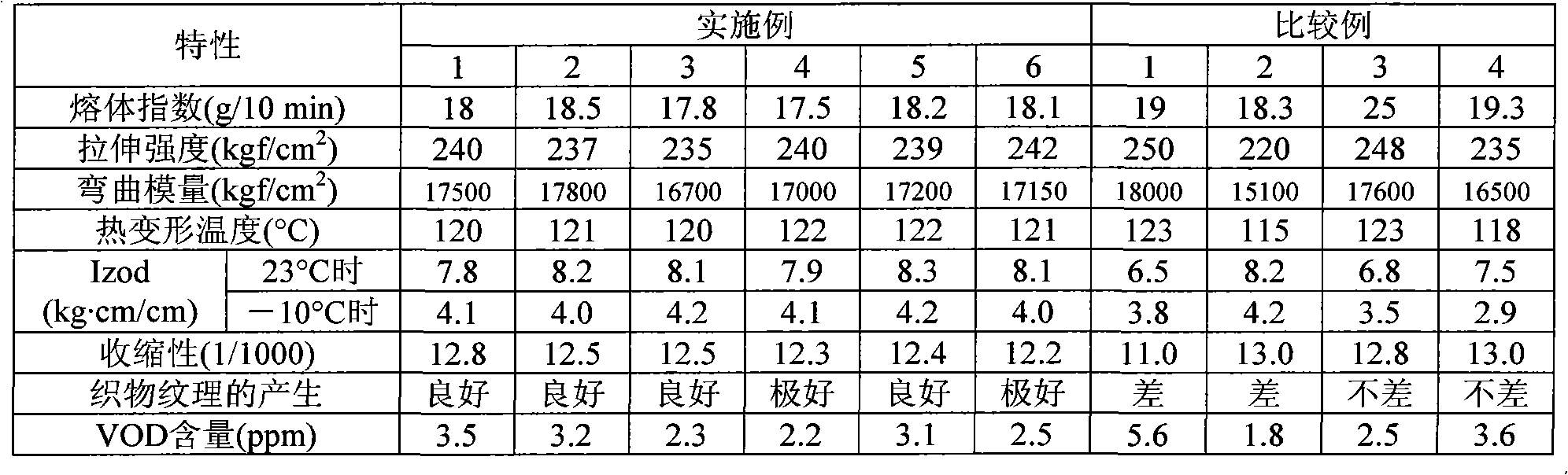

Embodiment 1-6 and comparative example 1-4

[0034] A polypropylene resin composition was prepared using the components and their ratios shown in Table 1 below, and was molded using an injection molding machine (model: LGE110, LS Cable Ltd.) at a cylinder temperature of 220°C and a molding temperature of 50°C. It was injection molded into a test piece (molded body).

[0035] [Table 1]

[0036]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of tacticity | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| degree of tacticity | aaaaa | aaaaa |

Login to View More

Abstract

According to preferred aspects, the present invention provides a polypropylene resin composition for creating a fabric texture, the polypropylene resin composition comprising: a polypropylene resin containing at least two selected from the group consisting of a homopolypropylene, a propylene-ethylene copolymer, and a high crystalline polypropylene (HCPP); a polypropylene elastomer; an ethylene-[alpha]-olefin copolymer; an inorganic filler; a cellulose fiber; and a volcanic rock. A molded product prepared using the polypropylene resin composition of the present invention has matt properties, do not cause odor due to their excellent VOC adsorption capabilities, and have excellent properties such as low temperature impact resistance, scratch resistance, etc.

Description

technical field [0001] The present invention generally relates to polypropylene resin compositions for producing textile textures. More specifically, the present invention relates to a polypropylene resin composition comprising: a polypropylene resin containing at least two selected from the group consisting of homopolypropylene, propylene-ethylene copolymer and high crystalline polypropylene (HCPP); polypropylene elastic ethylene-α-olefin copolymers; inorganic fillers; cellulose fibers; and volcanic rocks. Background technique [0002] Due to the trend of high-quality vehicles in recent years, plastic parts for vehicle interior parts such as door trims, pillar trims, etc. are required to be of excellent quality. Therefore, in order to improve vehicle interior quality, fiber covering or coating is used for plastic parts used for vehicle interior parts. However, the method of wrapping or coating plastic parts using fibers has some disadvantages, such as cost increase due to...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/12C08L23/16C08L67/02C08L23/08C08L77/00C08L1/02C08K3/22C08K3/34

CPCC08L23/0815C08L2205/02C08L23/12C08L23/10C08L23/142C08L2205/16C08L1/00C08L2666/02C08L23/16C08K7/02B60R13/00

Inventor 卢定均金大植张庚勋安秉佑刘廷烈

Owner HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com