Continuous quenching cooling system for strip metal

A cooling system and metal technology, applied in the direction of quenching device, heat treatment equipment, furnace, etc., can solve the problems of scratches on the surface of the saw blade, uneven cooling, unreasonable structure of the cooling system, etc., and achieve the effect of uniform cooling temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

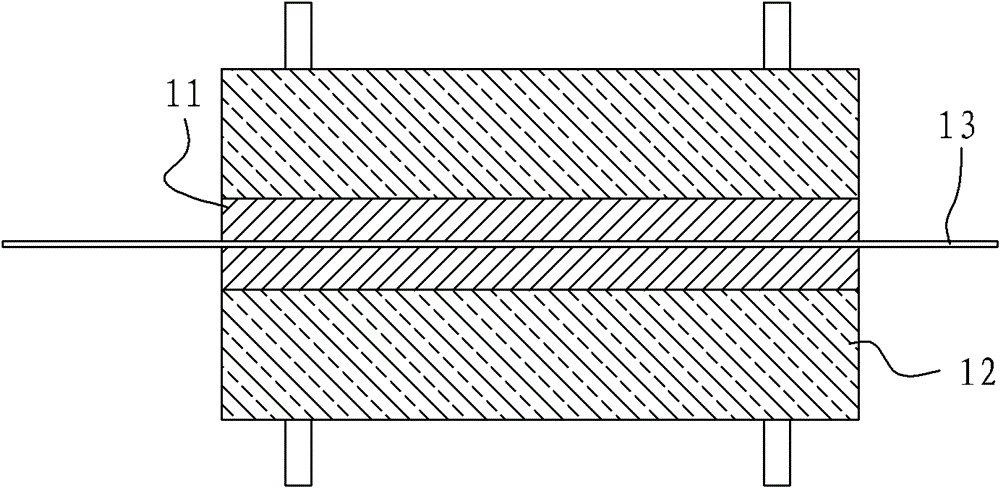

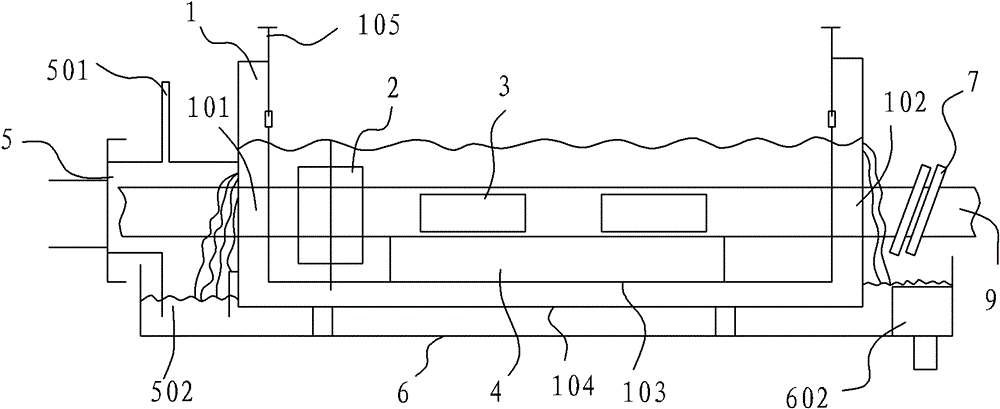

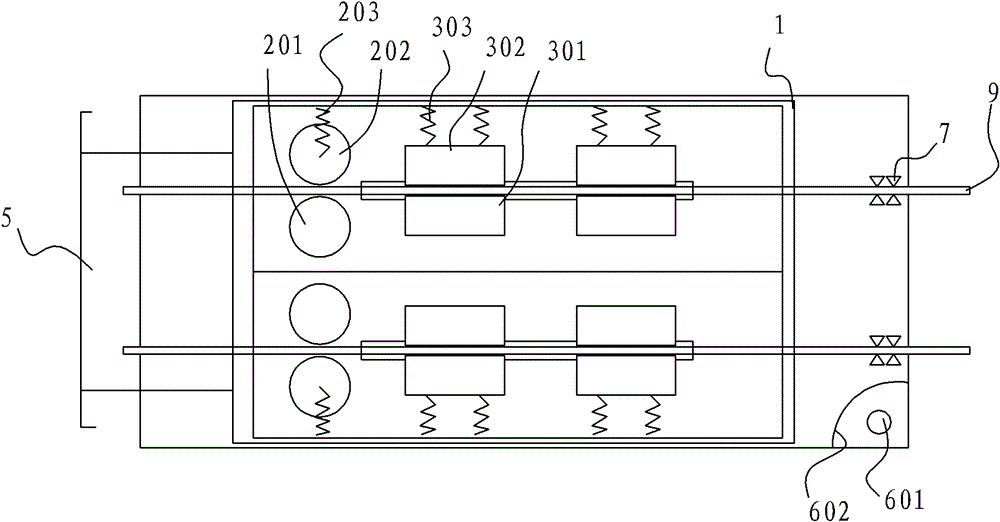

[0022] As shown in the figure, a strip-shaped metal continuous quenching cooling system is mainly used for quenching and cooling of saw blades. It includes a cooling tank 1 and a cooling liquid circulation mechanism for supplying cooling liquid to the cooling tank 1. The cooling tank 1 is used to hold the cooling liquid. , When the strip metal passes through the cooling liquid in the cooling tank, it is cooled.

[0023] The cooling tank 1 is roughly rectangular, and its opposite side walls are respectively provided with a feed inlet 101 and a discharge outlet 102 at the same height. In this embodiment, there are two feed inlets and two discharge outlets, and they correspond to each other. Of course, the cooling tank 1 can be in other shapes, such as circular. When cooling, the strip metal can pass through the feed port 101 and the discharge port 102 horizontally. A strip metal guide mechanism 2 and a straightening mechanism 3 are arranged in the cooling tank 1 .

[0024] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com