Method and arrangement in tail threading of a web in the dryer section of a fiber web machine

A fiber web machine and drying section technology, which is applied in papermaking, papermaking machines, textiles and papermaking, etc., can solve problems such as insufficient description of technical personnel, damage to valuable equipment and equipment of papermaking machines, and uncertainty in tail threading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

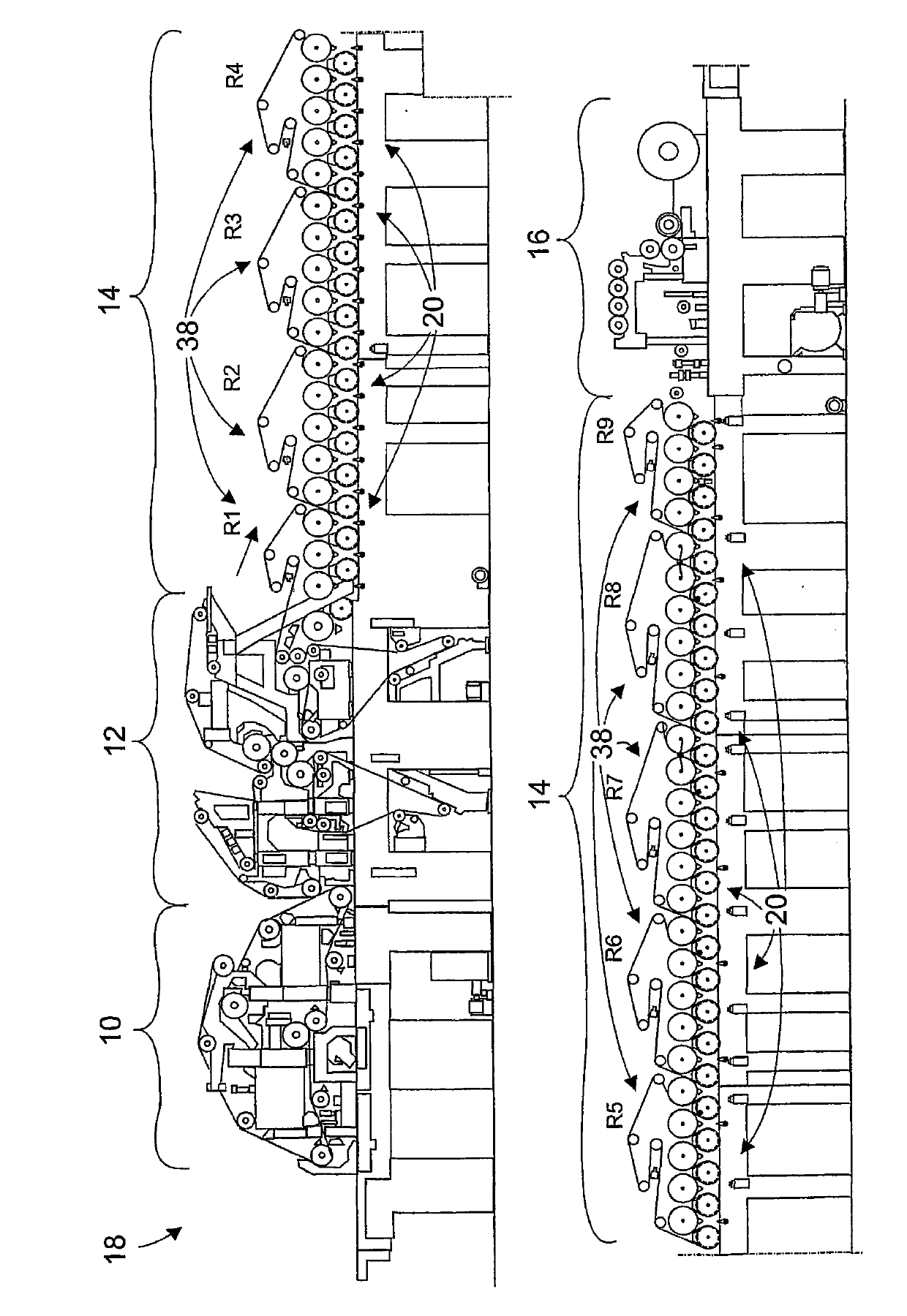

[0025] figure 1 A conventional fiber web machine 18 is shown viewed from the side. The fiber web machine 18 comprises (as a continuous partial entity) a forming section 10 , a press section 12 , a drying section 14 and a finishing section 16 . according to figure 1 In the fiber web machine of , the finishing section only consists of machine rolls. The method and apparatus of the present invention are designed for tail threading in the dryer section 14 of a fiber web machine 18 using only an above-located single fabric run 20 . The drying section 14 includes a continuous drying cylinder bank 38 according to figure 1 There are 9 dryer groups 38 in the fiber web machine. Dryer groups 38 are identified individually by symbols R1-R9. Advantageously, the web is full width during tail threading.

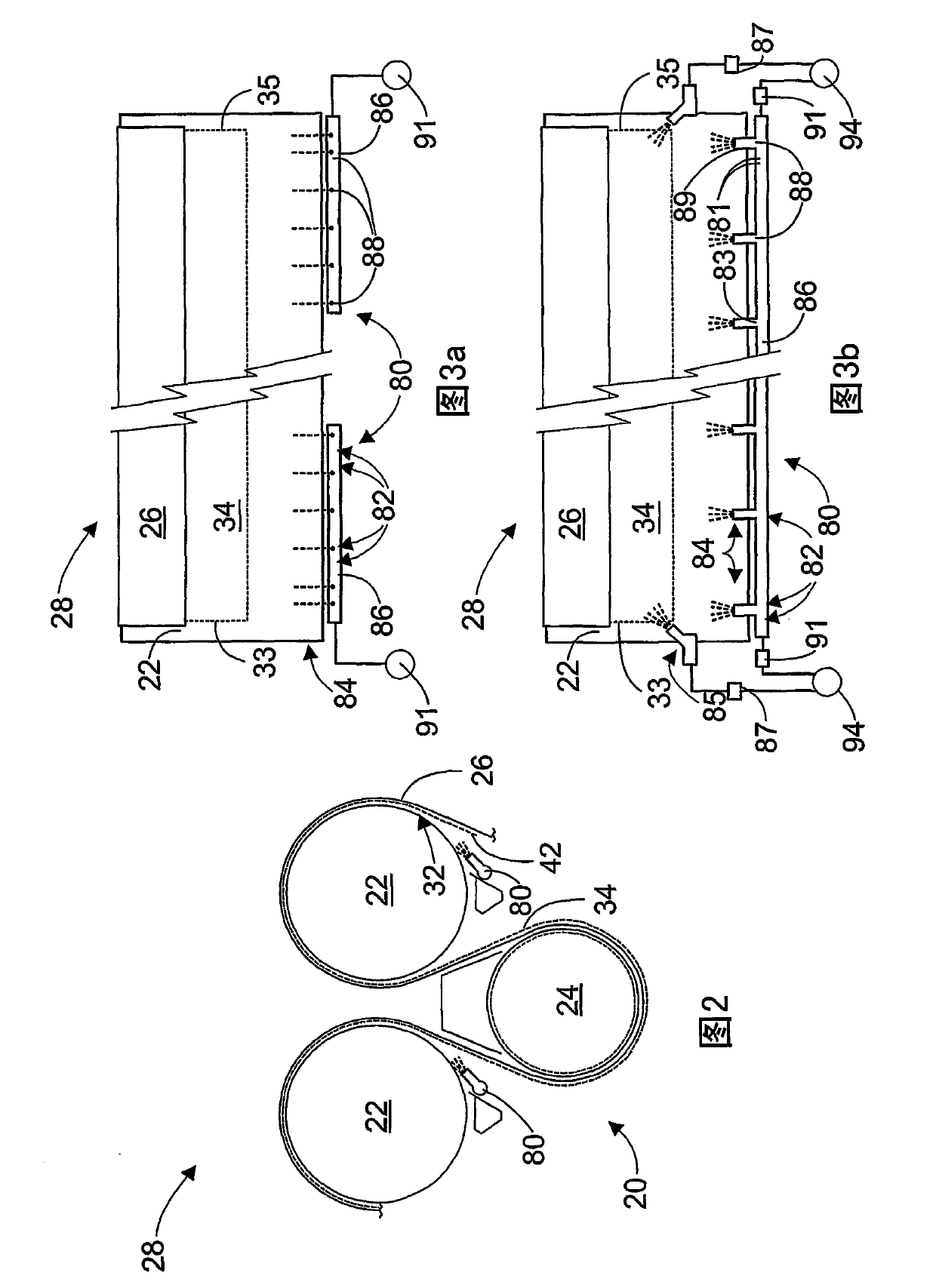

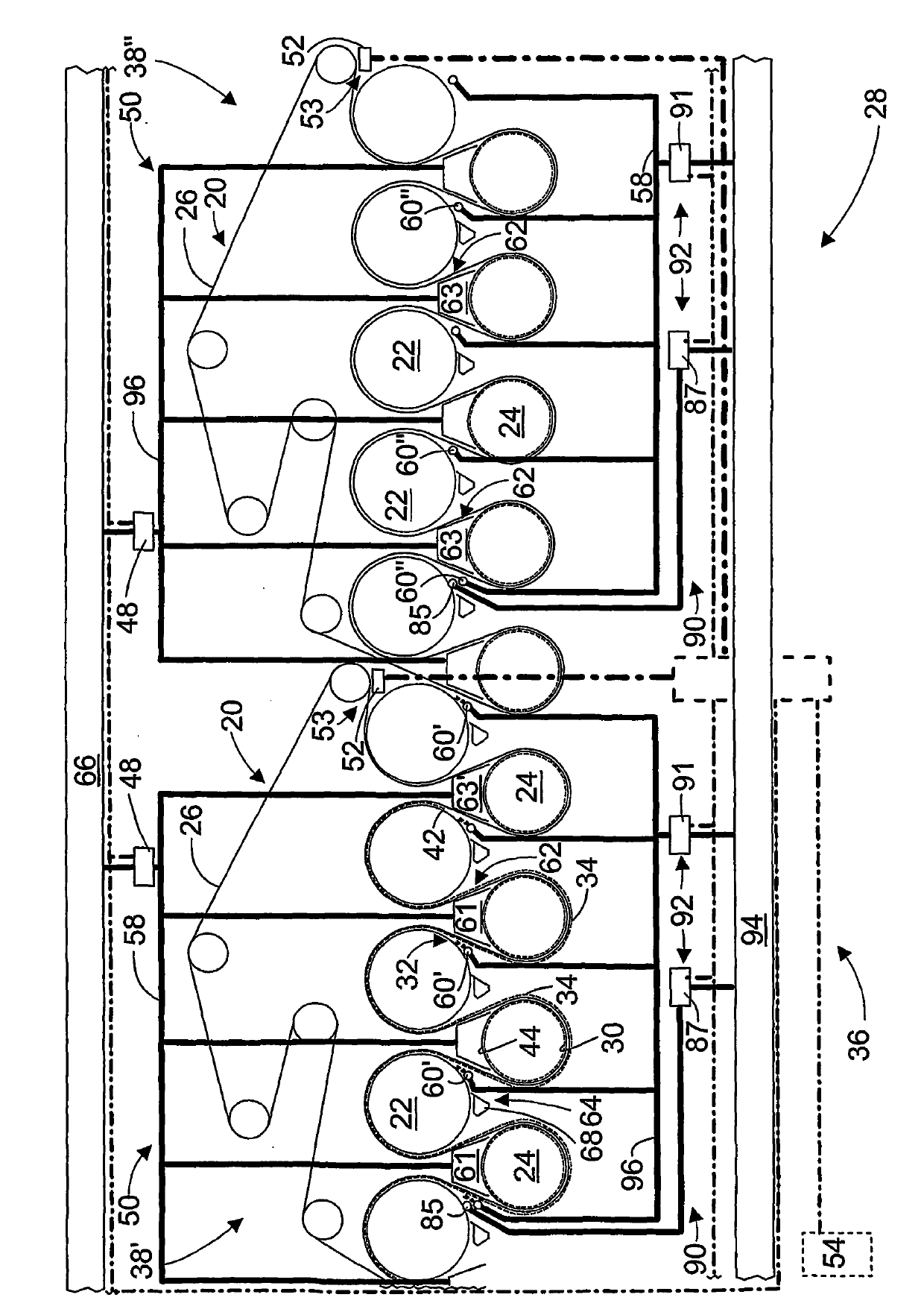

[0026] In the tail threading of the web 34 in the dryer section 14, figure 1 The illustrated fiber web machine 18 may have figure 2 Shown is a device 28 according to the invention....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com