Motor extending shaft of full-automatic sewage pollution-cleaning machine

A shaft extension, fully automatic technology, applied in the direction of mobile filter element filter, filter separation, separation method, etc., can solve the problems of small load torque, function elimination, etc., and achieve the effect of increasing the transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

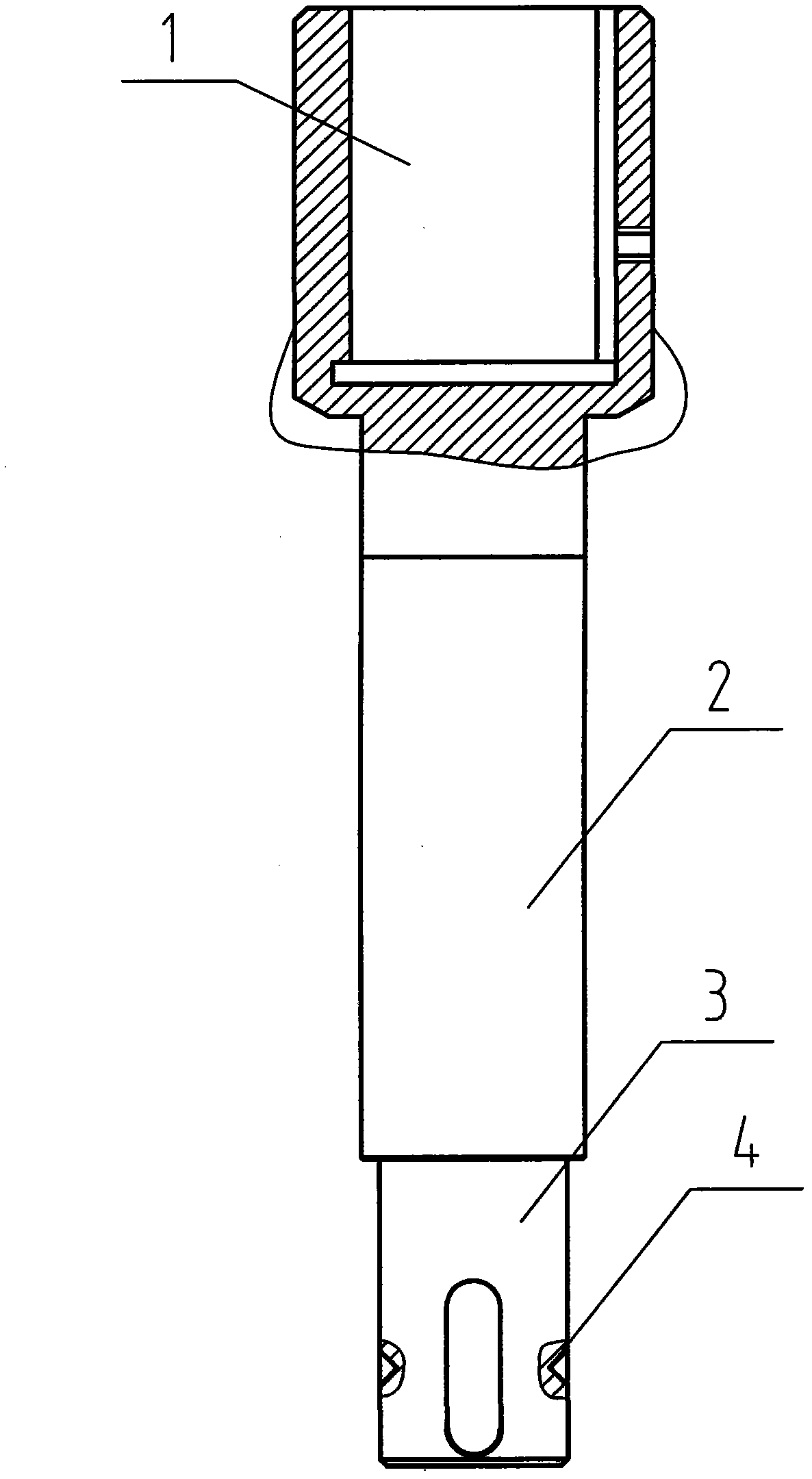

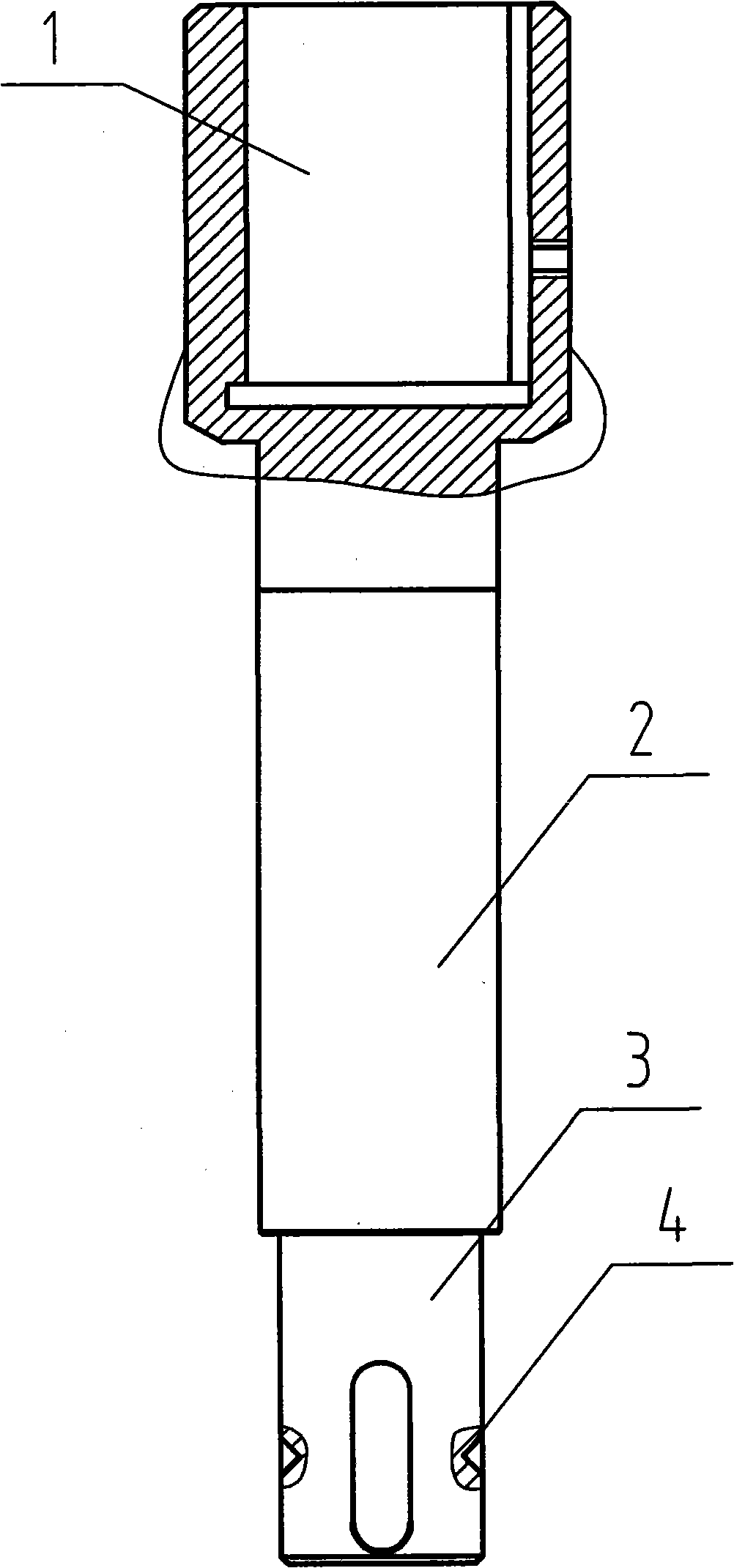

[0011] Specific examples of the present invention are attached figure 1 Shown, now compare figure 1 The specific instructions are as follows:

[0012] Such as figure 1 As shown, the motor extension shaft includes a motor extension shaft body 2 and a single key shaft 3 at the lower part. The motor extension shaft body is provided with a motor extension shaft hole 1, and the output shaft of the reducer is inserted into the motor extension shaft hole 1. Two fastening screws 4 are provided on both sides of the shaft 3.

[0013] The present invention is not limited to this embodiment, and any equivalent concepts or changes within the technical scope disclosed in the present invention are all included in the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com