Airflow atomizer

An atomizer and air-flow technology, which is applied in the direction of injection devices and liquid injection devices, can solve the problems of poor product particle size uniformity and insufficient atomization ability, and achieve the effects of reducing energy consumption, simple structure, and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

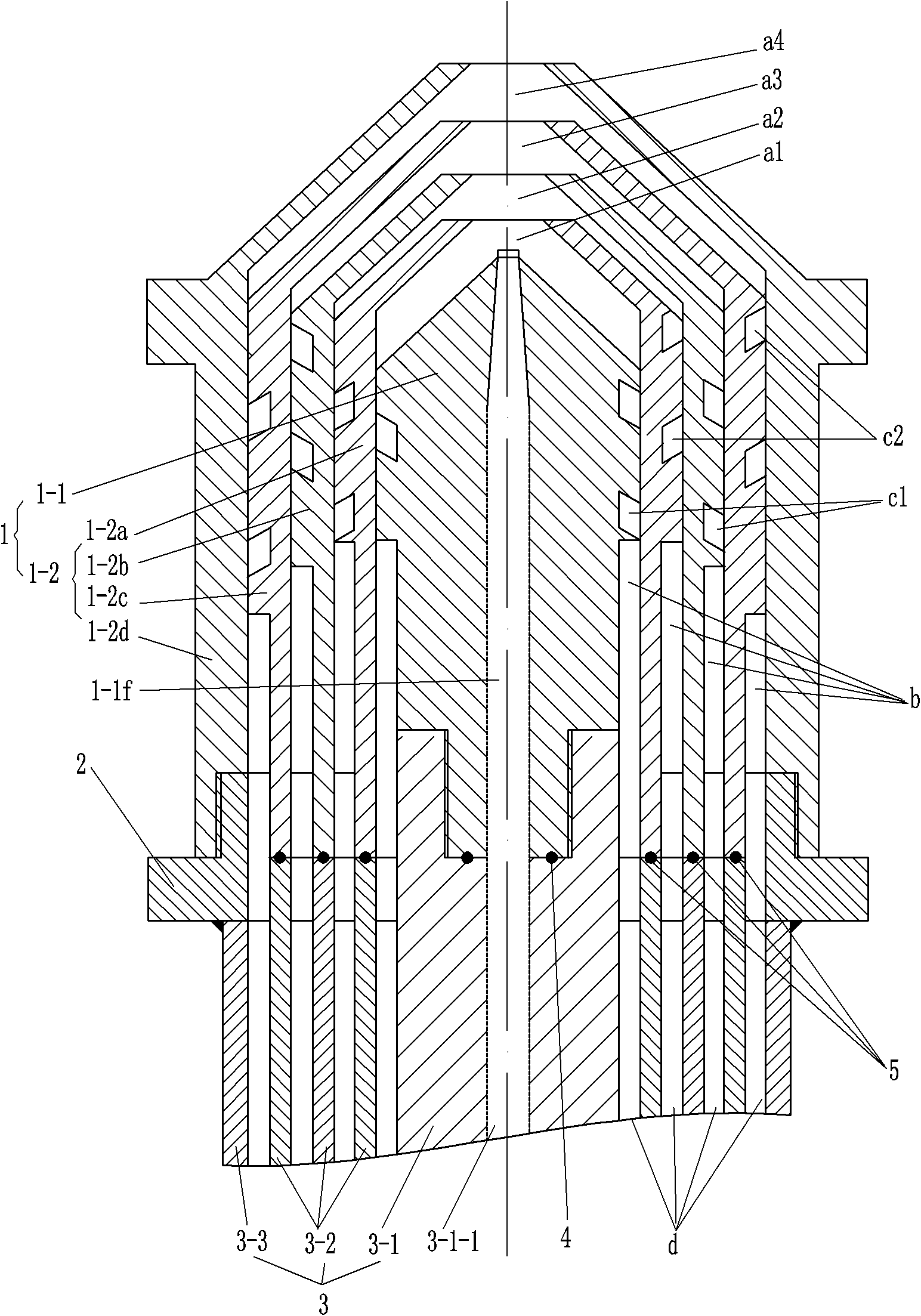

[0028] see Figure 1 to Figure 11 , This embodiment includes a spray gun 1, a hollow connecting seat 2 and a support tube 3. The spray gun 1 has five overlapping nozzles, the middle nozzle is the liquid nozzle 1-1, and the other four nozzles are the gas nozzle 1-2. The gas nozzle 1-2 includes a first gas nozzle 1-2a, a second gas nozzle 1-2b, a third gas nozzle 1-2c, a fourth gas nozzle 1-2d, and a fourth gas nozzle 1-2d from the inside to the outside. It is the gas nozzle at the outermost layer, and at the same time plays the role of the shell. The support tube 2 is connected with the outermost gas nozzle of the spray gun 1, that is, the fourth gas nozzle 1-2 d by the hollow connecting seat 2.

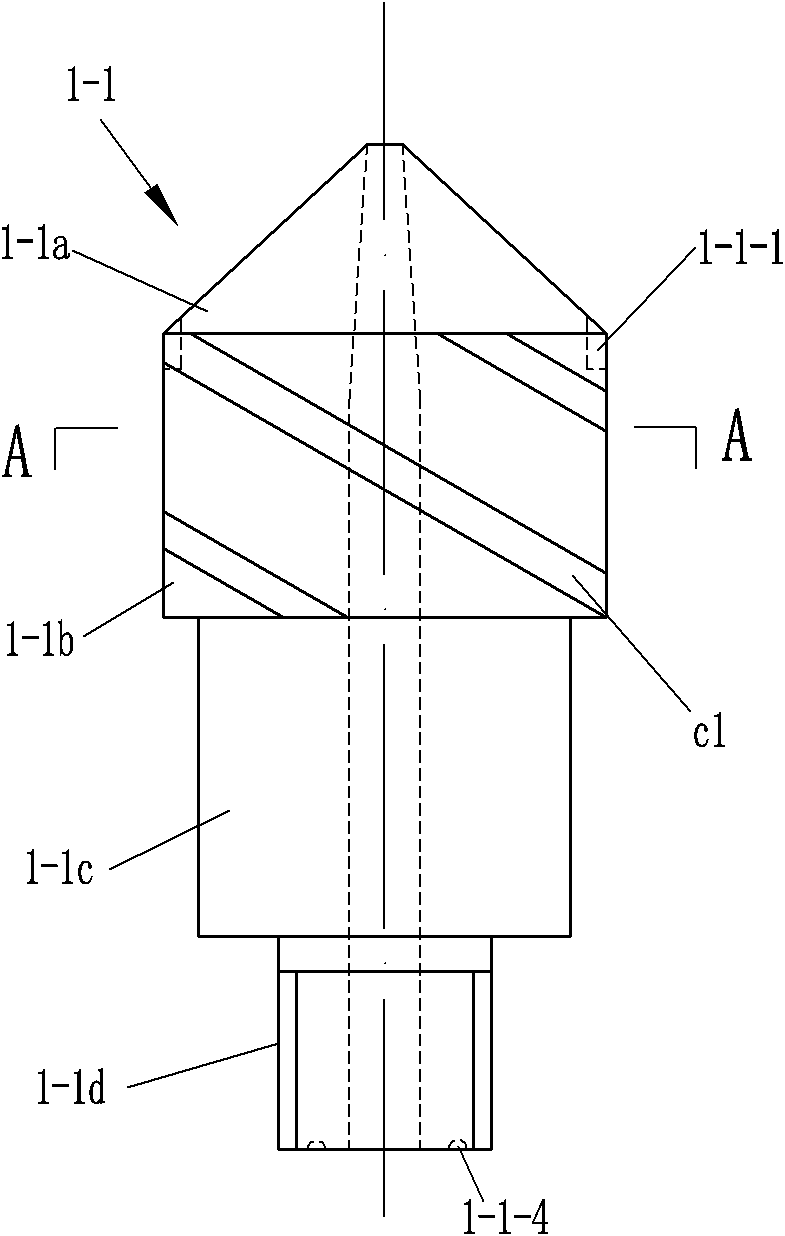

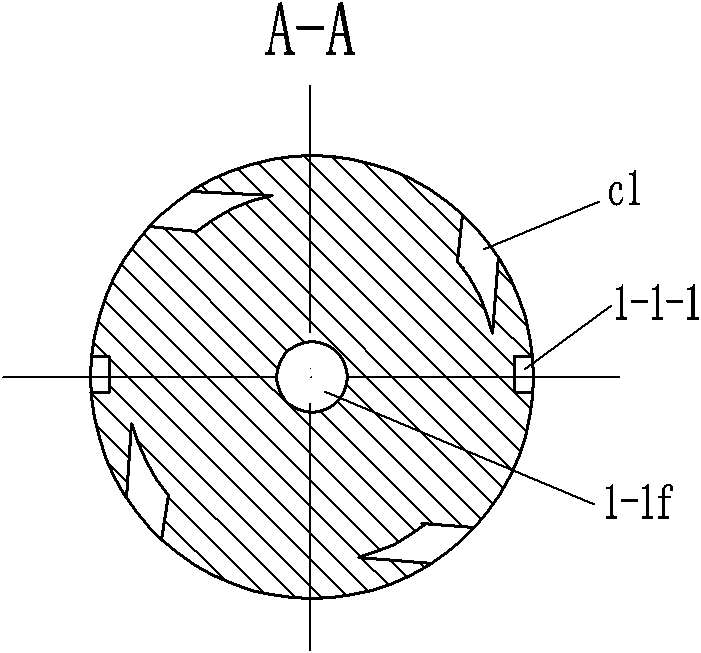

[0029] The material liquid nozzle 1-1 includes a tapered head 1-1a and a cylinder, and the material liquid nozzle 1-1 is provided with a material liquid hole 1-1f. The gas nozzle 1-2 includes a tapered head and a cylinder. The inner cavity of the conical head 1-2a-a of the first gas n...

Embodiment 2

[0038] see Figure 12 to 14 , Example 2 has 4 nozzles stacked one on top of the other, the middle nozzle is the liquid nozzle 1-1, and the other 3 nozzles are the gas nozzle 1-2. The gas nozzle 1-2 includes a first gas nozzle 1-2a, a second gas nozzle 1-2e, and an outermost gas nozzle 1-2d from the inside to the outside, and the spiral grooves on two adjacent nozzles rotate in opposite directions. Compared with Embodiment 1, there is one less gas nozzle, and the gap of the second gas nozzle 1-2e is an annular gap, and other structures are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com